RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

Page 4

FOUNDATION

Each RXB PLUS Rotary Screw Compressor Unit is shipped

mounted on a wood skid which must be removed prior to unit

installation. CAUTION: Allow space for servicing both ends

of the unit. A minimum of 24 inches is recommended.

The first requirement of the compressor foundation is that it

must be able to support the weight of the compressor pack-

age including coolers, oil, and refrigerant charge. Screw

compressors are capable of converting large quantities of

shaft power into gas compression in a relatively small space

and a mass is required to effectively dampen these rela-

tively high frequency vibrations.

Firmly anchoring the compressor package to a suitable foun-

dation by proper application of grout and elimination of pip-

ing stress imposed on the compressor is the best insurance

for a trouble free installation. Use only the certified general

arrangement drawings from Frick to determine the mount-

ing foot locations and to allow for recommended clearances

around the unit for ease of operation and servicing. Foun-

dations must be in compliance with local building codes and

materials should be of industrial quality.

The floor should be a minimum of 6 inches of reinforced con-

crete and housekeeping pads are recommended. Anchor bolts

are required to firmly tie the unit to the floor. Once the unit is

rigged into place (See HANDLING and MOVING), the feet must

then be shimmed in order to level the unit. The shims should

be placed to position the feet roughly one inch above the house-

keeping pad to allow room for grouting. An expansion-type

epoxy grout must be worked under all areas of the base with

no voids and be allowed to settle with a slight outward slope so

oil and water can run off of the base.

When installing on a steel base, the following guidelines should

be implemented to properly design the system base:

1. Use I-beams in the skid where the screw compressor will be

attached to the system base. They should run parallel to the

package feet and support the feet for their full length.

2. The compressor unit feet should be continuously welded to

the system base at all points of contact, or bolted.

3. The compressor unit should not be mounted on vibration

isolators in order to hold down package vibration levels.

4. The customer’s foundation for the system base should fully

support the system base under all areas, but most certainly

under the I-beams that support the compressor package.

When installing on the upper floors of buildings, extra pre-

cautions should be taken to prevent normal package vibra-

tion from being transferred to the building structure. It may

be necessary to use rubber or spring isolators, or a combi-

nation of both, to prevent the transmission of compressor

vibration directly to the structure. However, this may increase

package vibration levels because the compressor is not in

contact with any damping mass. The mounting and support

of suction and discharge lines is also very important. Rub-

ber or spring pipe supports may be required to avoid excit-

ing the building structure at any pipe supports close to the

compressor package. It is best to employ a vibration expert

in the design of a proper mounting arrangement.

In any screw compressor installation, suction and discharge lines

should be supported in pipe hangers (preferably within 2 ft. of

vertical pipe run) so that the lines won’t move if disconnected

from the compressor. See table for Allowable Flange Loads.

A licensed architect should be consulted to determine the

proper foundation requirements for any large engine or tur-

bine drive.

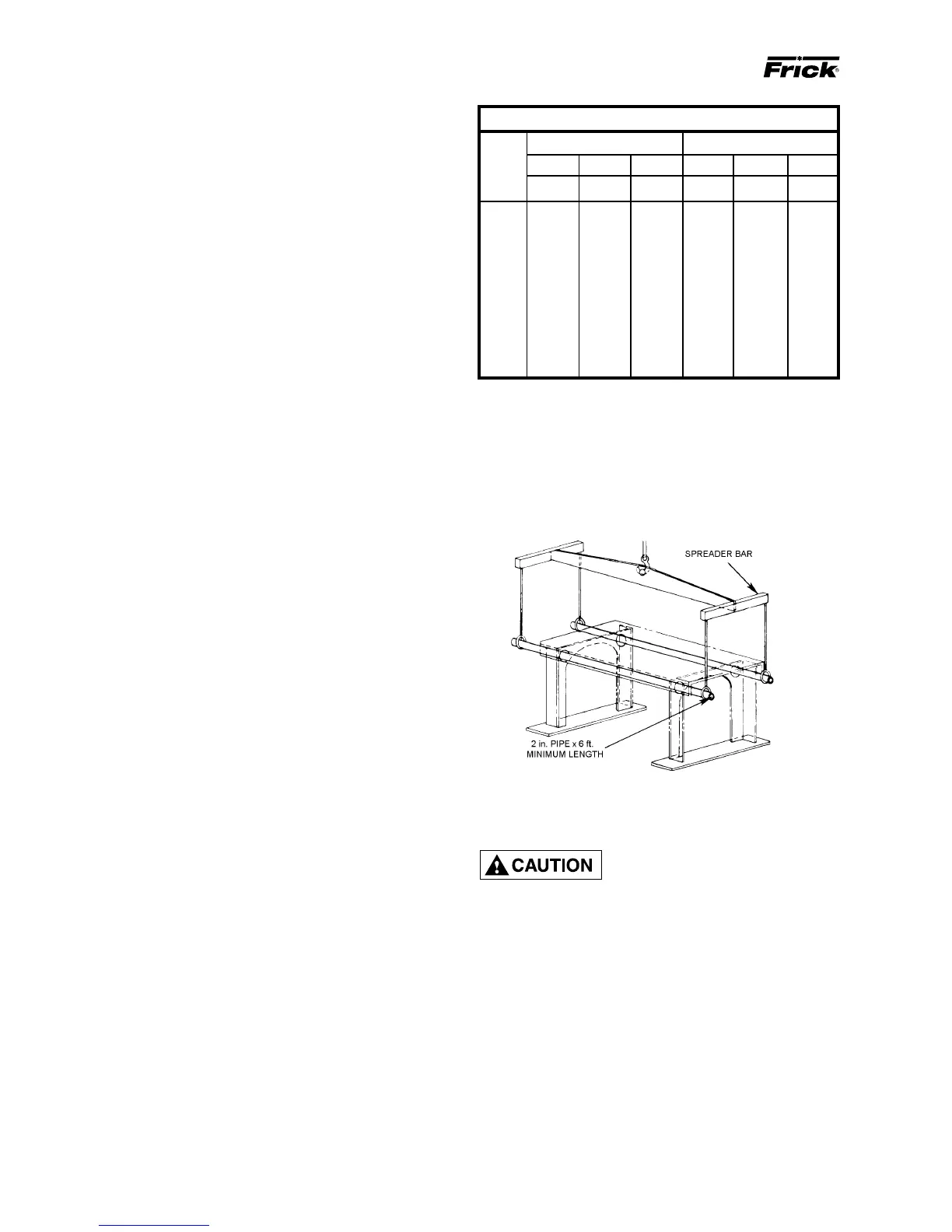

INSTALLATION

NOZ.

SIZE

NPS

(in.)

AXIAL VERT. AXIAL VERT. LAT.LAT.

M

R

M

C

M

L

PV

C

V

L

1

1.25

1.5

2

3

4

5

6

8

10

12

14

50

50

75

125

250

400

450

650

900

1200

1500

2000

50

50

75

125

250

400

450

650

900

1200

1500

2000

50

50

100

150

225

300

400

650

1500

1500

1500

1700

25

25

40

70

175

200

400

750

1000

1200

1500

1800

25

25

40

70

175

200

400

750

1000

1200

1500

1800

25

25

50

100

250

400

425

1000

1500

1500

1500

2000

ALLOWABLE FLANGE LOADS

MOMENTS (ft-lbf) LOAD (lbf)

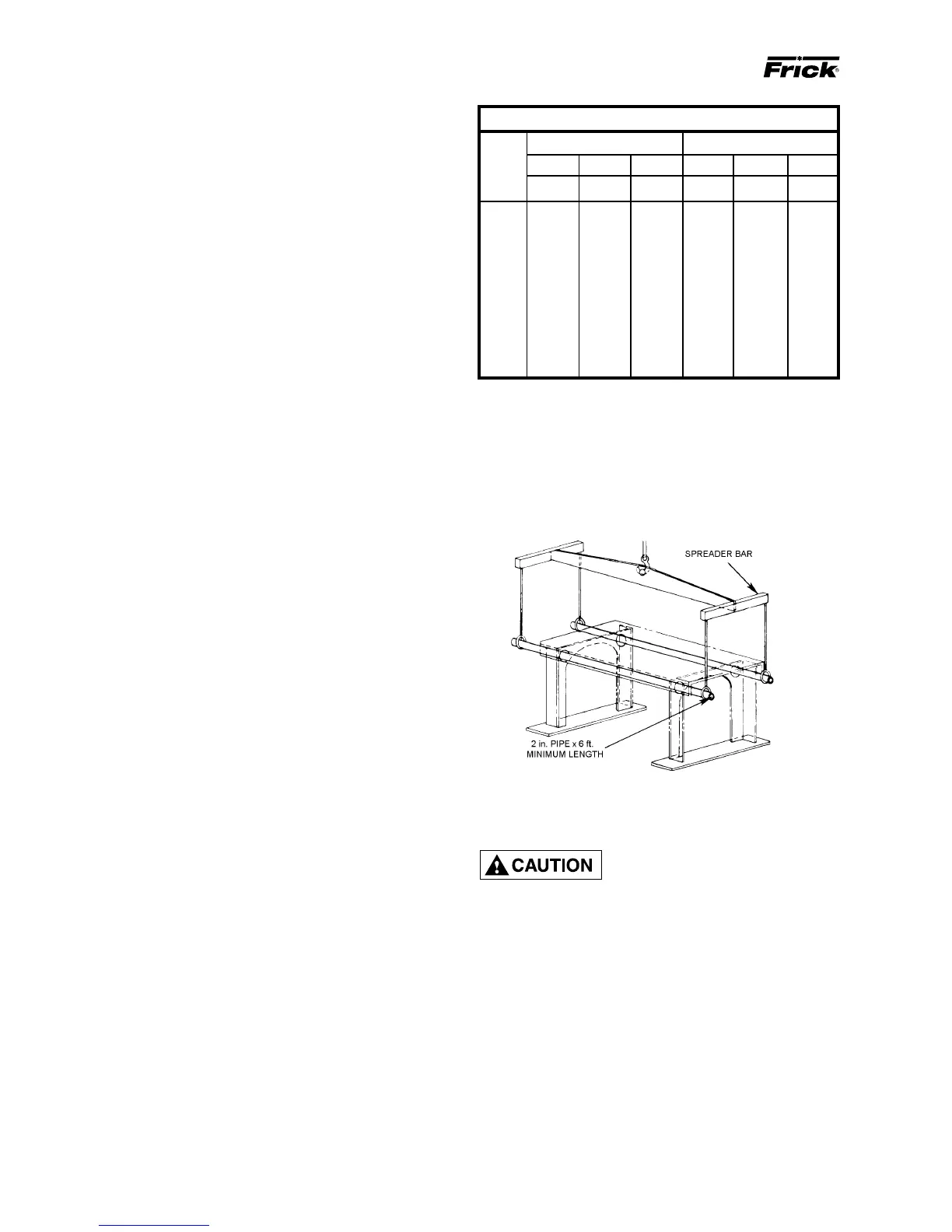

HANDLING AND MOVING

THIS UNIT MAY BE TOP HEAVY.

USE CARE WHILE HANDLING.

Spreader bars should be used on

both the length and width of the package to prevent

bending of oil lines and damage to the package.

The unit can be moved with rigging, using a crane or forklift.

The recommended method is to insert lengths of 2" pipe

through the lifting holes in the vertical supports (see FIG. 1).

Alternatively, hooks may be used in rigging, inserting them

in the lifting holes (see FIG. 2).

Use CAUTION in locating the lifting ring. If no motor is

mounted, the lifting ring should be moved off center to the

compressor side of the unit because 60 percent of the weight

is toward the compressor end. If a motor is mounted, ap-

propriate adjustment in the lifting point should be made to

compensate for motor weight. Adjustment of the lifting point

must also be made for any additions to the standard pack-

age, such as an external oil cooler, etc., as the center of

balance will be affected.

FIG. 1 - RECOMMENDED LIFTING METHOD

When applying screw compressors at high pressures, the

customer must be prepared for package vibration and noise

higher than the values predicted for normal refrigeration duty.

Proper foundations and proper installation methods are vi-

tal; and even then, sound attenuation or noise curtains may

be required to reduce noise to desired levels.

For more detailed information on Screw Compressor Foun-

dations, please request Frick publication S70-210 IB.

Loading...

Loading...