RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

Page 34

OPERATION

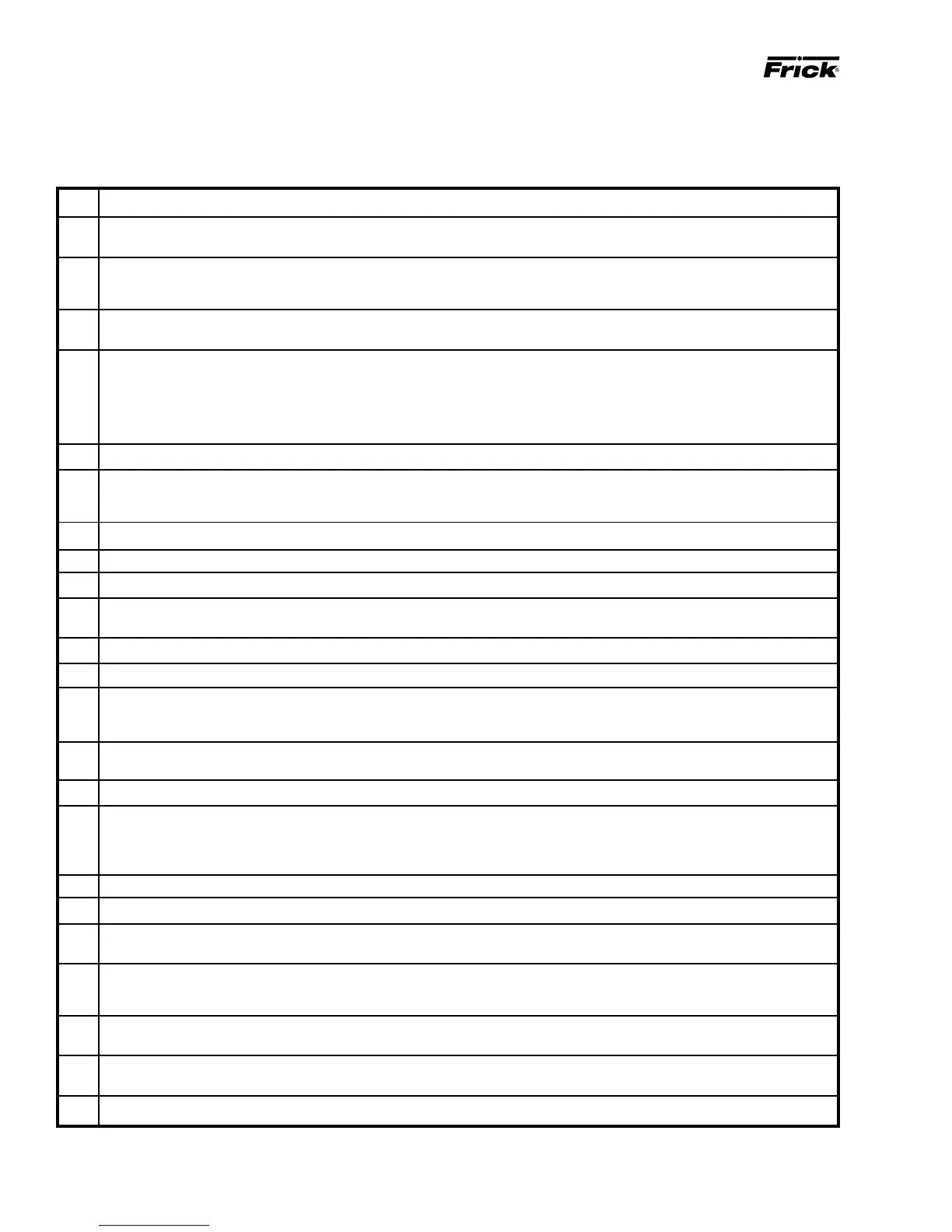

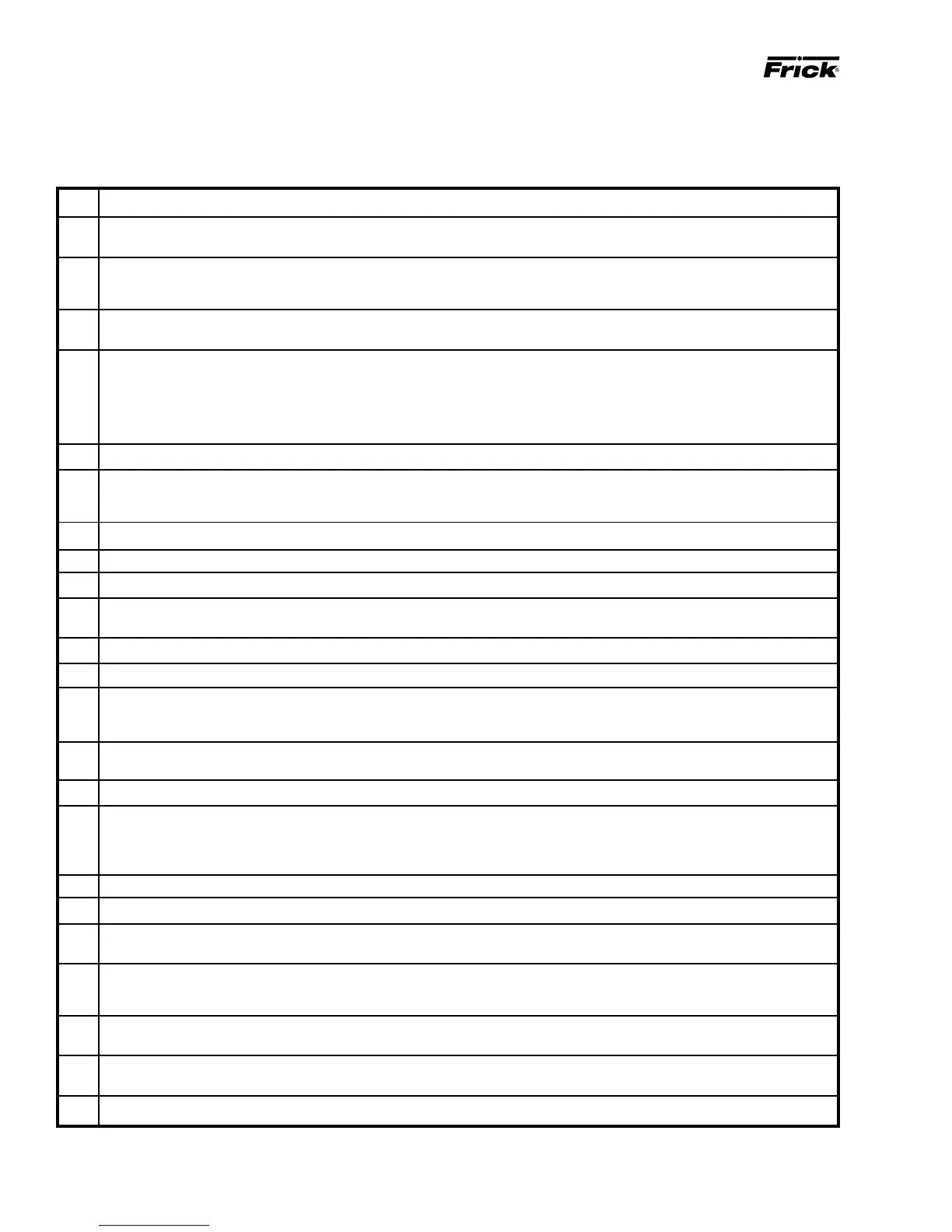

PRESTART CHECKLIST

All check points in the following list must be completed before placing the compressor unit in operation. Only when the checklist

is completed will the unit be ready for initial start-up.

CHECKPOINT

Ammonia Units: Only refrigerant grade Ammonia as specified by International Institute of Ammonia Refrigeration

(IIAR) Bulletin # 110, Section 3.3 should be used with FRICK equipment.

Unit pressure test. Close suction and discharge service valves, and isolation valve to low pressure transducer.

Introduce pressure to unit and check for leaks. CAUTION: Do NOT exceed 80% of relief valve and/or 100% of

the vessel’s design working pressure.

Charge unit with proper amount and grade of oil. Oil level should be between the two

sight glasses on the oil separator.

Evacuate unit and system to 29.88" Hg. vacuum (1000 microns) to ensure that the system

is free of moisture and noncondensable gases. Additional information regarding

evacuation is detailed in the following publications:

AMMONIA - International Institute Of Ammonia Refrigeration (IIAR) Bulletin # 110, Section 5.4.

HALOCARBONS - Refrigeration Service Engineering Society (RSES) Service Application Manual,

Section 83, Forms 610-57 and 630-46.

Confirm that all field wiring is complete.

With coupling center removed, check for proper compressor motor rotation. COMPRESSOR

ROTATION IS CLOCKWISE WHEN FACING COMPRESSOR SHAFT. Check for proper alignment. OPEN

compressor motor disconnect. Replace coupling center.

If applicable, check Full-Time Oil Pump for correct rotation. OPEN oil pump motor disconnect.

Confirm that motor overload and CT is properly sized.

With ALL motor disconnects OPEN, turn control power ON and check ALL voltages.

Check that oil heater circuit is on. CAUTION: The oil heater should be on 24 hours

before initial start-up is attempted.

Confirm that the Emergency Stop Button is not depressed. Disengage by gently twisting to the left.

Confirm Microprocessor function. Rotate through displays.

Rotate to the ADJUSTABLE setpoints display (2 pages) and enter setpoints including DAY, DATE, and TIME.

Return to the Operating display, then rotate back to the ADJUSTABLE setpoints display to confirm that the

proper setpoints have registered. Press [F1] to return to the Operating display.

Rotate to the ANNUNCIATOR display. Confirm that all setpoints are normal and that no

alarm or cutout indications are present. Press [F1] to return to the Operating display.

Open all oil circuit service valves to allow normal oil flow.

If applicable, start the oil pump by turning the oil pump switch to HAND. Confirm oil

pressure buildup pump rotation. Separator oil level may drop as oil filter(s) and oil

cooler fills up. Add oil as required. Allow oil pump to operate 10 minutes to flush the

lubricating circuit. Shut down oil pump. Place the oil pump switch in the AUTO mode.

Open discharge and suction service valves.

Open the oil return needle valve located at the bottom of the coalescer section of the oil separator.

Open all hydraulic control valves for the slide valve (compressor loading and unloading)

and the slide stop (volumizer).

Open all required oil cooling valves. LIQUID INJECTION: service valves should be fully

open with the exception of the bleed valve which should be opened 1/4 turn. WATER-COOLED

OIL COOLER: confirm adequate water supply is present and adjust water-regulating valve to midrange.

Close economizer service valves, if applicable. The economizer can be put into service

once normal operation is established.

Confirm that the entire refrigeration system is ready for compressor operation and that

sufficient load is available for compressor start-up.

Close compressor motor main disconnect.

Loading...

Loading...