RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

Page 10

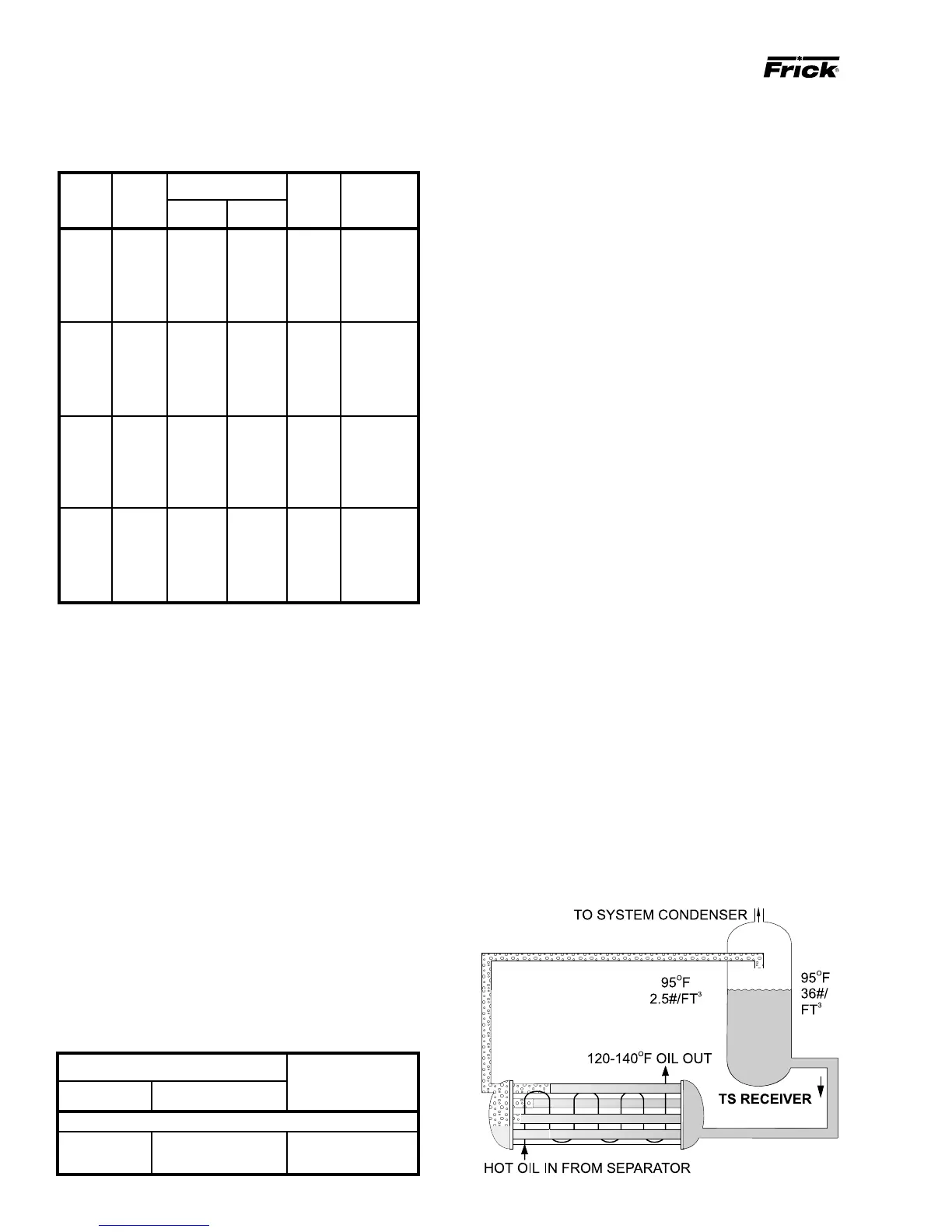

OIL COOLER DATA TABLE

SIZE - Inches APPROX

WATER FLOW

COOLER WATER CONN RANGE (GPM)

5 Foot Lengths

6" DIA. 1 NPT 10 – 23

8" DIA. 1-1/4 NPT 35 – 60

* 100 ft. liquid line. For longer runs, increase line size ac-

cordingly.

Liquid line sizes and the additional receiver volume (quan-

tity of refrigerant required for 5 minutes of liquid injection oil

cooling) are given in the following table:

LIQ. LINE SIZE* FLOW LIQUID

REF RXB RATE VOLUME

MODEL PIPE TUBING (lb.) CU.FT.

SCH 80 OD 5 MIN

12 1/2 – 10 .3

15 1/2 – 12.5 .4

HIGH 19 1/2 – 15 .4

STAGE 24 1/2 – 20 .6

R-717 30 1/2 – 25 .7

39 1/2 – 30 8

50 3/4 – 40 1.1

12 3/4 5/8 30 .4

15 3/4 5/8 37.5 .5

HIGH 19 3/4 5/8 45 .6

STAGE 24 3/4 7/8 60 .8

R-22 30 3/4 7/8 75 1.0

39 3/4 7/8 95 1.3

50 1 1 125 1.7

12 1/2 – 2.1

15 1/2 – 2.5 .1

BOOST- 19 1/2 – 3.5 .1

ER 24 1/2 – 4.5 .1

R-717 30 1/2 – 5.5 .2

39 1/2 – 6.5 .2

50 1/2 –- 8.5 .3

12 3/4 1/2 6 .1

15 3/4 1/2 7 .1

BOOST- 19 3/4 1/2 9 .1

ER 24 3/4 1/2 12 .2

R-22 30 3/4 1/2 14.5 .2

39 3/4 1/2 18 .3

50 3/4 5/8 24 .3

WATER-COOLED OIL COOLING (OPTIONAL)

The shell and tube-type, water-cooled oil cooler is mounted

on the unit complete with all oil piping. The customer must

supply adequate water connections and install the two-way

water regulating valve. It is recommended that (local codes

permitting) the water regulator be installed on the water outlet

connection. Insert the water regulator valve bulb and well in

the chamber provided on the oil outlet connection. Deter-

mine the size of the water-cooled oil cooler supplied with

the unit, then refer to table for the water connection size

and water flow range (GPM). The water supply must be

sufficient to meet the required flow.

It is imperative that the condition of cooling water and closed

loop fluids be analyzed and maintained regularly and as

necessary to prevent corrosion of heat exchanger surfaces.

The oxygen content of river water and some other cooling

water sources will oxidize steel tubes and cause premature

failure. Careful attention to water treatment is essential to

ensure adequate life of steel cooler tubes if cooling tower

water is used. The condition of heat exchanger tubes should

be checked semiannually to prevent hazard.

NOTE: The water regulating valve shipped with the unit

will be sized to the specific flow for the unit.

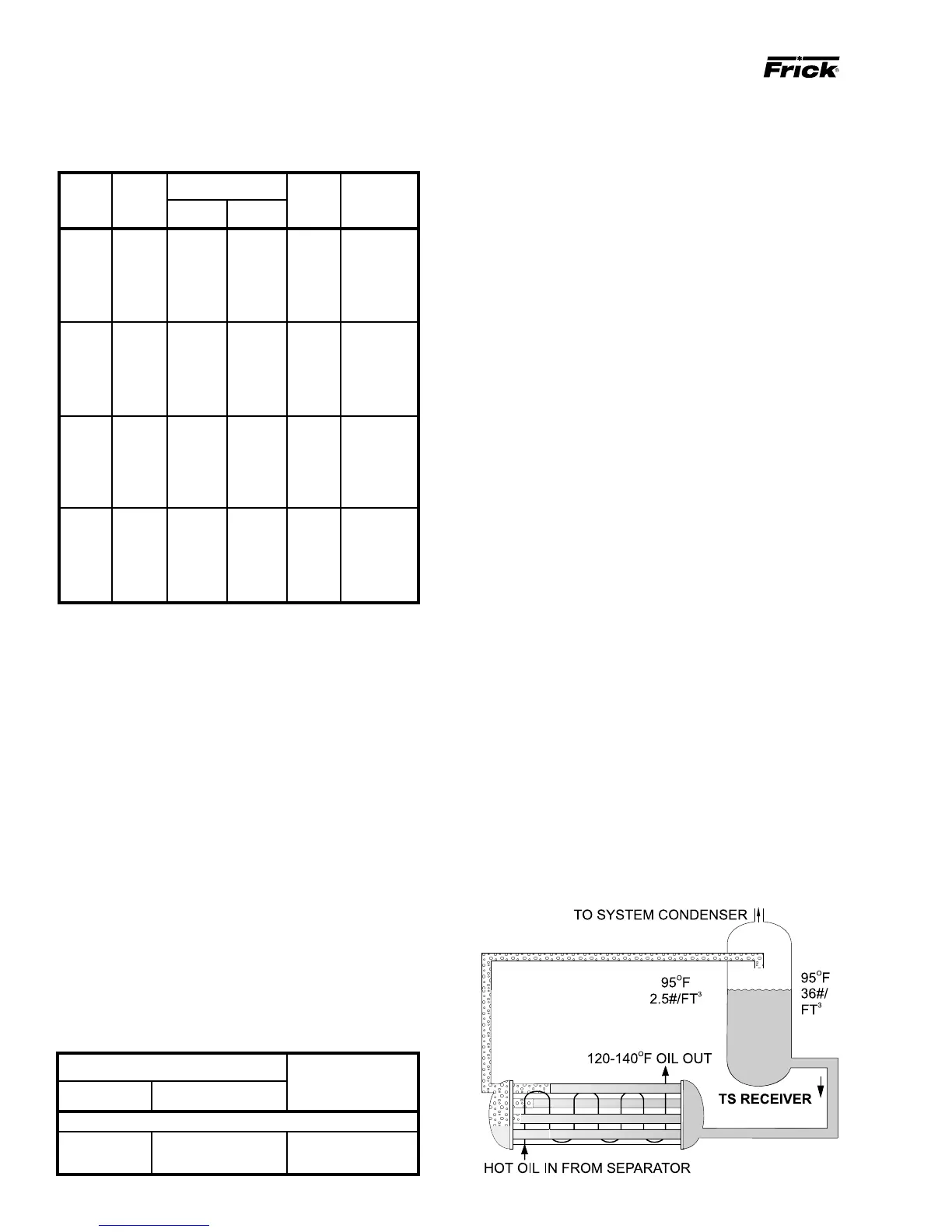

THERMOSYPHON OIL COOLING (OPTIONAL)

Thermosyphon oil cooling is an economical, effective method

for cooling oil on screw compressor units. Thermosyphon

cooling utilizes liquid refrigerant at condenser pressure and

temperature which is partially vaporized at the condenser

temperature in a shell and tube- or plate-type vessel cool-

ing the oil to within 15

O

F of that temperature. The vapor, at

condensing pressure, is vented to the condenser inlet and

reliquified. This method is the most cost effective of all cur-

rently applied cooling systems since no compressor capac-

ity is lost or compressor power penalties incurred. The va-

por from the cooler need only be condensed, not com-

pressed. Refrigerant flow to the cooler is automatic, driven

by the thermosyphon principle, and cooling flow increases

as the oil inlet temperature rises.

EQUIPMENT - The basic equipment required for a ther-

mosyphon system consists of:

1. A source of liquid refrigerant at condensing pressure and

temperature located in close proximity to the unit to mini-

mize piping pressure drop. The liquid level in the refrigerant

source must be 6 to 8 feet above the center of the oil cooler.

2. A shell and tube- or plate-type oil cooler with a 300 psi

minimum design working pressure on both the oil and re-

frigerant sides.

Due to the many variations in refrigeration system design

and physical layout, several systems for ensuring the above

criteria are possible.

SYSTEM OPERATION - Liquid refrigerant fills the cooler

tube side up to the Thermosyphon receiver liquid level.

Water or hot oil (above the liquid temperature) flowing

through the cooler will cause some of the refrigerant to boil

and vaporize in the tubes. The vapor rises in the return line.

The density of the refrigerant liquid/vapor mixture in the re-

turn line is considerably less than the density of the liquid in

the supply line. This imbalance provides a differential pres-

sure that sustains a flow condition to the oil cooler. This re-

lationship involves:

1. Liquid height above the cooler.

2. Oil heat of rejection.

3. Cooler size and piping pressure drops.

INSTALLATION

Loading...

Loading...