RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

Page 33

OPERATION

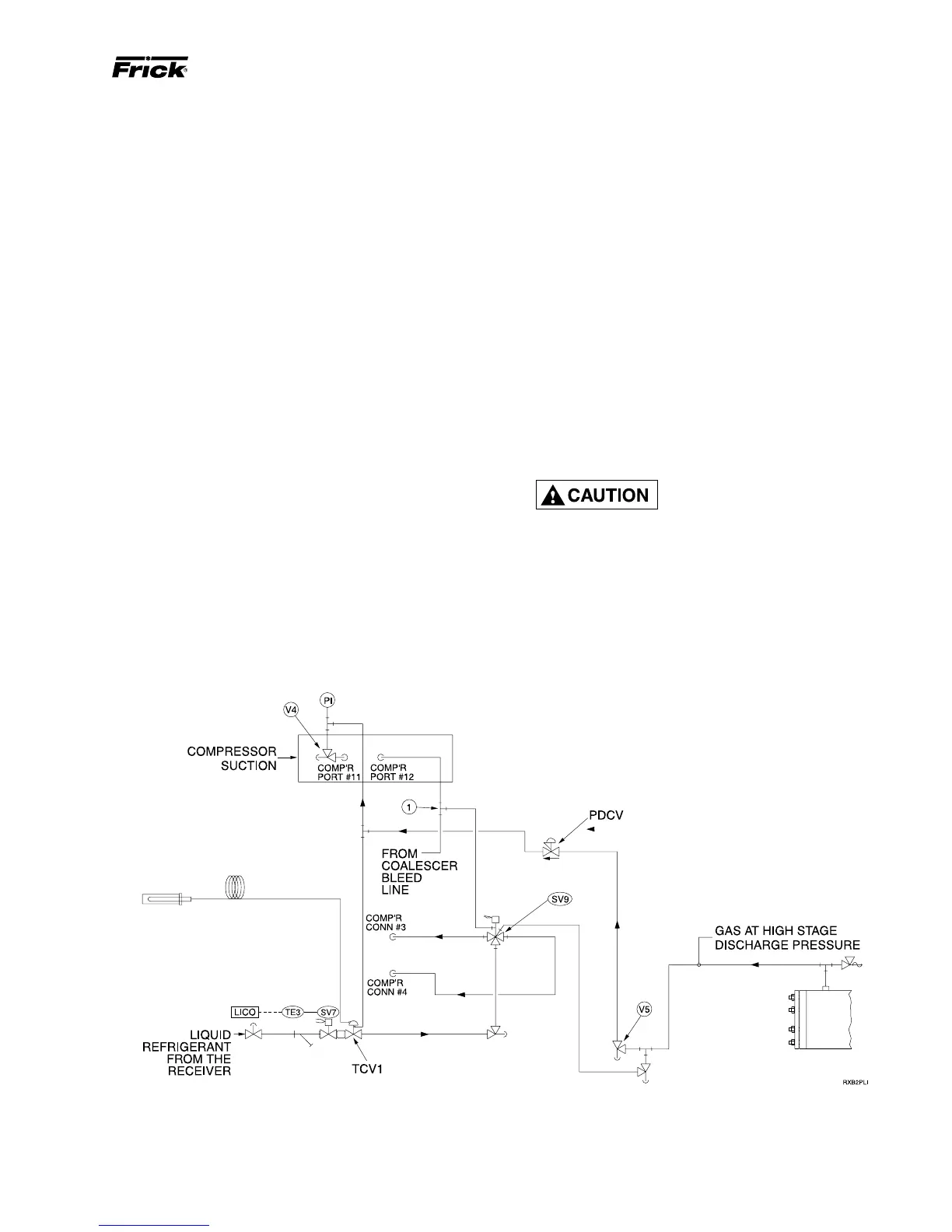

DUAL-PORT LIQUID INJECTION

The dual-port liquid injection system is designed to obtain

the most efficient compressor performance at high and low

compression ratios by permitting injection of liquid refriger-

ant into one of two ports on the compressor.

The dual-port system contains all the components of the

single-port system with the addition of a double-acting sole-

noid valve SV9 and operates as outlined.

Solenoid valve SV7 is energized by the microprocessor when

the temperature element (TE3), installed in the oil piping

after the oil filter, exceeds the LICO setpoint. Liquid refriger-

ant is then passed through the temperature control valve

TCV1 to the double-acting solenoid valve SV9. Depending

on the compressor’s operating volume ratio Vi, the micropro-

cessor will select the flow of the liquid refrigerant to either

compressor port 3 or port 4.

When the compressor operates at 3.5 or 2.2, Vi compressor

port 3 (low Vi) supplies the liquid cooling. At 5.0 Vi, port 4

(high Vi) supplies the liquid cooling.

The temperature control valve TCV1 is equalized to a con-

stant back pressure by the differential pressure control valve

PDCV.

Both the differential pressure control valve PDCV and the

double-acting solenoid valve SV9 use discharge gas to

maintain downstream pressure. The gas downstream of both

valves is bled off to the compressor suction to ensure steady

and constant operation of the valves.

LIQUID INJECTION

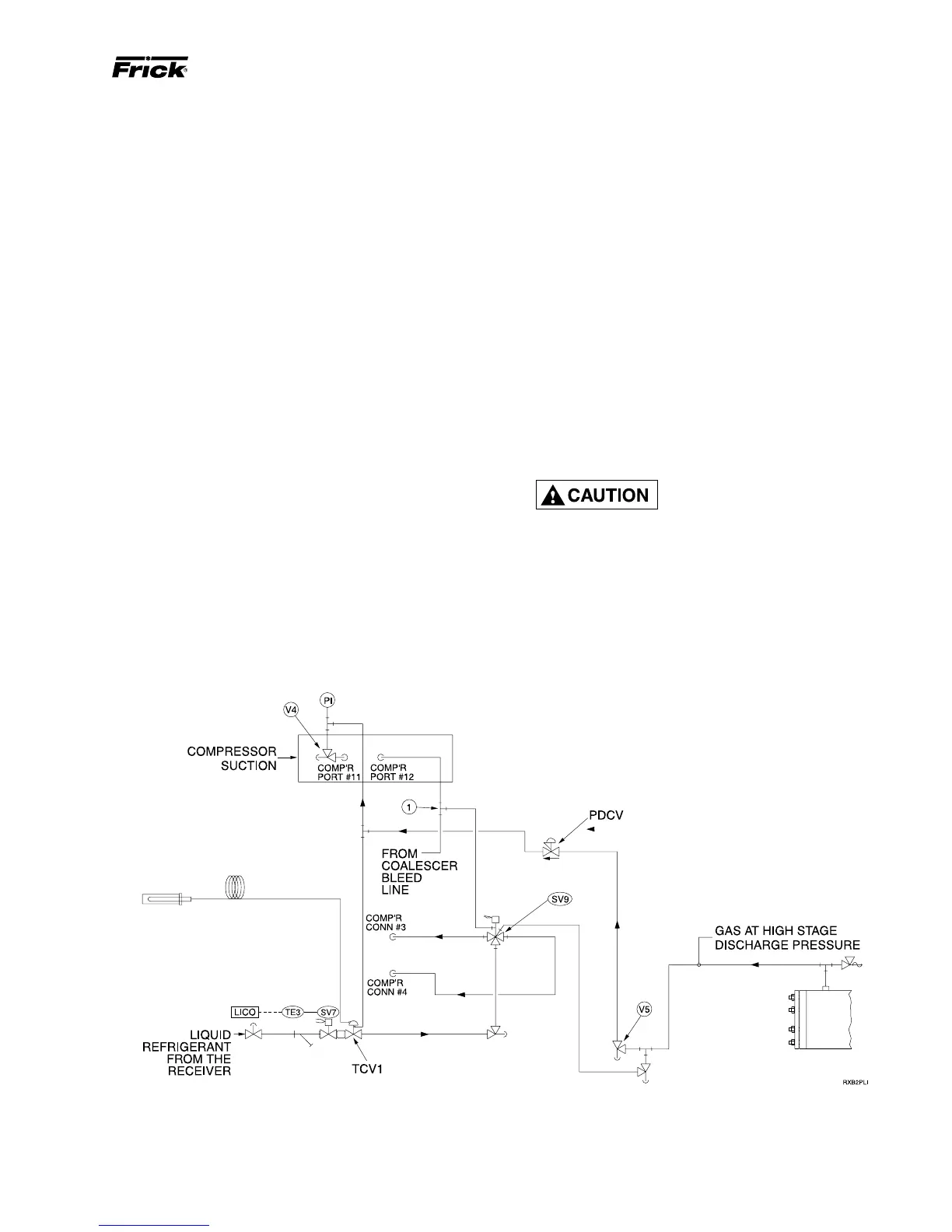

ADJUSTMENT PROCEDURE

1. Close vent valve (V4).

2. Open service valve (V5) until approximately 80 PSIG is

registered at the Pressure Indicator (PI).

3. Open vent valve (V4) until 75 PSIG is registered at the

Pressure Indicator (PI).

4. Monitor the oil temperature of the compressor. If the oil

temperature rises above 130

O

F (R-717) or 150

O

F (R-22),

open vent valve (V4) a very small amount. This will reduce

pressure on the equalizer and allow more refrigerant to flow

to the compressor. If the oil temperature drops below 110

O

F

(R-717) or 130

O

F (R-22), close vent valve (V4) a very small

amount. This will increase pressure on the equalizer. The

ideal condition is to maintain an oil temperature as stable

as possible. An incorrectly tuned liquid injection system will

cause extreme swings in the discharge temperature and

the oil temperature.

The vent valve (V4) MUST be open

at least 1/4 turn during normal op-

eration. A higher initial pressure

(step 2) may be required.

Loading...

Loading...