RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

Page 14

INSTALLATION

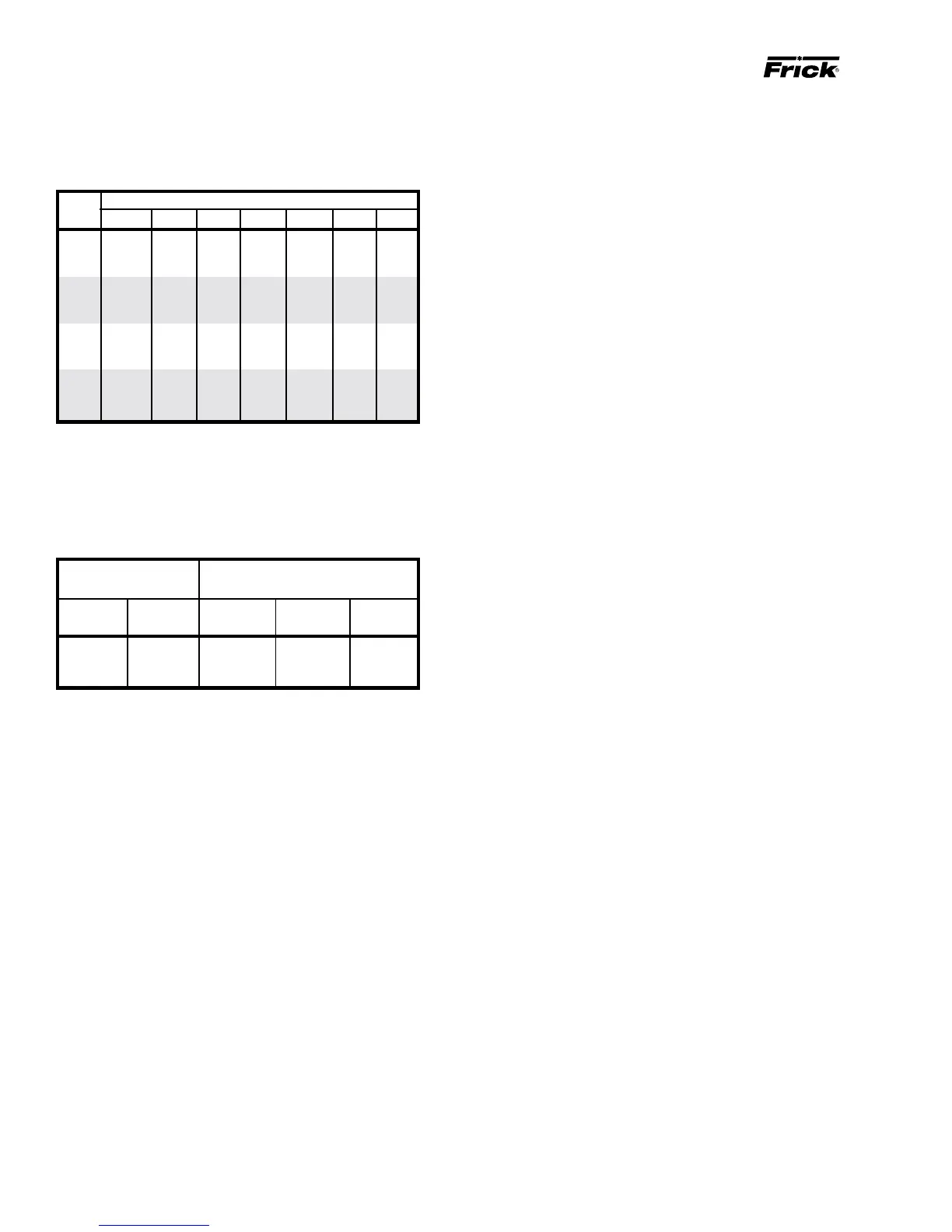

CURRENT TRANSFORMER (CT) RATIOS

The CT ratio for various motor sizes (with a 5 amp second-

ary) is given in the following table:

VOLTAGE

HP 200 230 380 460 575 2300 4160

20 100:5 100:5 100:5 100:5 100:5 - -

25 100:5 100:5 100:5 100:5 100:5 - -

30 200:5 100:5 100:5 100:5 100:5 - -

40 200:5 200:5 100:5 100:5 100:5 - -

50 200:5 200:5 100:5 100:5 100:5 - -

60 300:5 200:5 200:5 100:5 100:5 - -

75 300:5 300:5 200:5 200:5 100:5 - -

100 400:5 300:5 200:5 200:5 200:5 - -

125 500:5 400:5 300:5 200:5 200:5 - -

150 500:5 500:5 300:5 300:5 200:5 - -

200 800:5 600:5 400:5 300:5 300:5 100:5 50:5

250 800:5 800:5 500:5 400:5 300:5 100:5 50:5

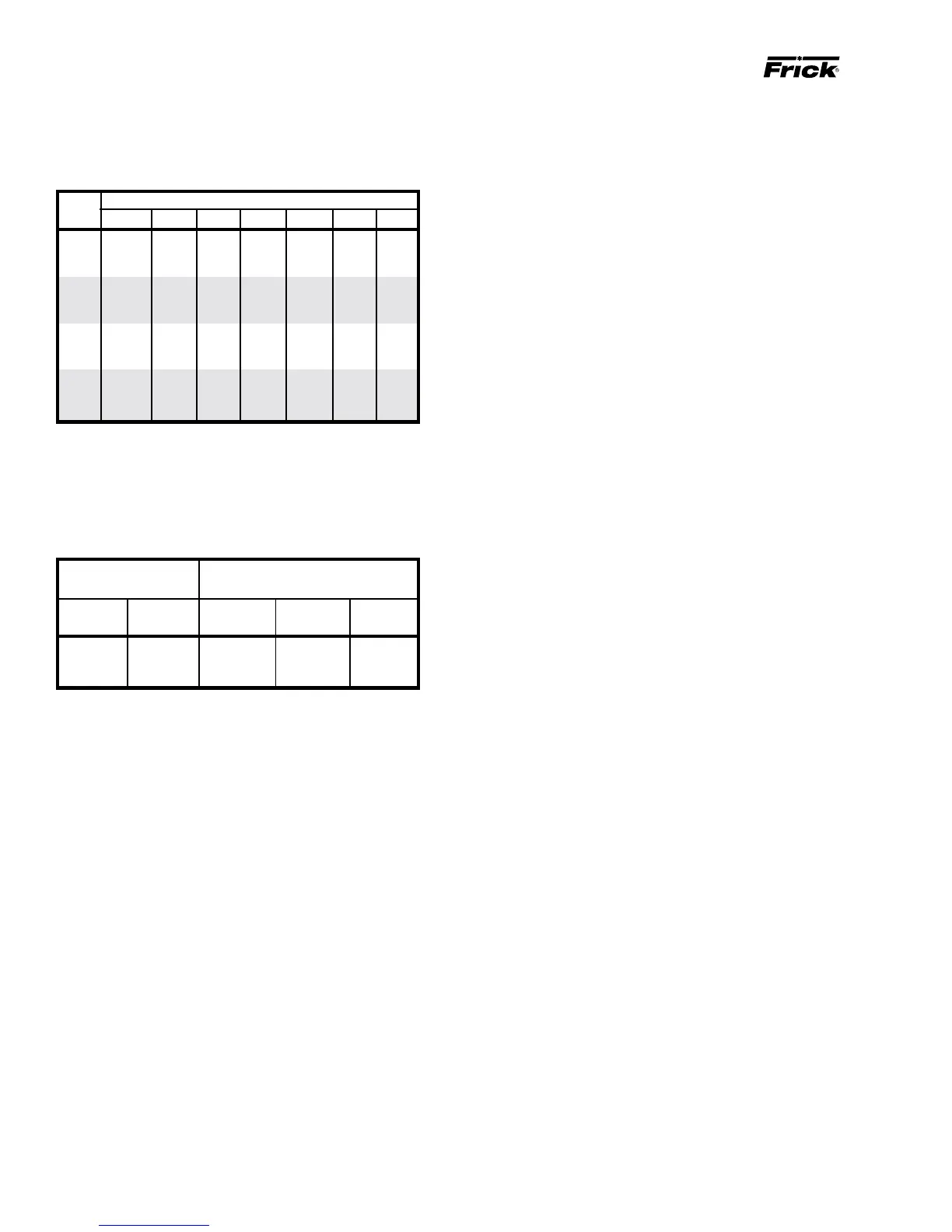

MINIMUM BURDEN RATINGS

The following table gives the minimum CT burden ratings.

This is a function of the distance between the motor starting

package and the compressor unit.

BURDEN MAXIMUM DISTANCE FROM

RATING FRICK PANEL

USING # USING # USING #

ANSI VA 14 AWG 12 AWG 10 AWG

B-0.1 2.5 15 ft 25 ft 40 ft

B-0.2 5 35 ft 55 ft 88 ft

B-0.5 12.5 93 ft 148 ft 236 ft

In addition to the starter package interlocks shown on the

starter package diagram, the following optional interlocks

are on the typical RXB PLUS Screw Compressor unit with

the SBC Microprocessor Control System wiring diagram:

1. Remote LOAD, UNLOAD, and RUN interlocks in case the

customer desires to operate the unit from a remote control

device.

2. Alarm Horn output.

3. Control solenoid valve for the economizer option.

For customer control options, consult FRICK Company.

NOTE: The microprocessor will not operate without

EPROM chips installed. When EPROM chips are not in-

stalled, the microprocessor display will typically indi-

cate two dark lines across both the upper and lower dis-

play screens.

BATTERY BACKUP

The battery backup prevents data loss during power inter-

ruption. It will maintain the adjustable setpoints stored in

RAM (Random Access Memory) for up to 1 year after power

loss. Expected battery life is 10 years. A trickle charge main-

tains the battery backup at peak charge when control volt-

age is present.

To prevent power loss, the battery backup is shipped dis-

abled. To enable the battery backup, a jumper pin located

near the top of the microprocessor circuit board (see illus-

tration page 52) must be moved from OFF (pins 1-2) to ON

(pins 2-3).

NOTE: It is not necessary to disconnect the battery

backup during extended downtime.

Loading...

Loading...