RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

Page 9

LIQUID INJECTION OIL COOLING

The liquid injection system provided on the unit is self-con-

tained but requires the connection of the liquid line sized as

shown in the table and careful insertion of the expansion

valve bulb into the thermowell provided in the separator. High

pressure gas is connected through the regulator to the ex-

ternal port on the liquid injection valve to control oil tem-

perature. Refer to the liquid injection piping diagram.

NOTE: For booster applications, the high pressure gas

connection must be taken from a high side source (high-

stage compressor discharge). This should be a minimum

3/8" line connected into the solenoid valve provided. This

gas is required by the expansion valve external port to

control oil temperature.

High-stage compressor units may be supplied with single-

port (low Vi) or dual-port (low Vi and high Vi), liquid injection

oil cooling. Single port will be furnished for low compression

ratio operation and dual port for high compression ratio op-

eration. Booster compressor units use single-port, liquid in-

jection oil cooling due to the typically lower compression

ratios.

The control system on high-stage units with dual-port, liq-

uid

injection oil cooling switches the liquid refrigerant supply to

the high port when the compressor is operating at higher

compression ratios (3.5 Vi and above) for best efficiency.

The following table gives the condensing temperature(s) with

the corresponding maximum evaporator temperature limit

for liquid injection usage and the minimum evaporator tem-

perature for a single-port application.

TABLE - EVAPORATOR TEMPERATURE with

SINGLE-PORT LIQUID INJECTION

MAXIMUM MINIMUM *

EVAPORATOR EVAP TEMP

CONDENS- TEMPERATURE FOR FOR

ING LIQUID INJECTION SINGLE PORT

TEMP USAGE (LOW Vi)

R-717 R-22 R-717 & R-22

75

O

F +10

O

F+5

O

F -23

O

F

85

O

F +25

O

F +15

O

F -17

O

F

95

O

F +35

O

F +25

O

F -11

O

F

105

O

F +40

O

F +35

O

F- 4

O

F

* Dual Injection Kit will be shipped by Frick

below these temperatures.

INSTALLATION

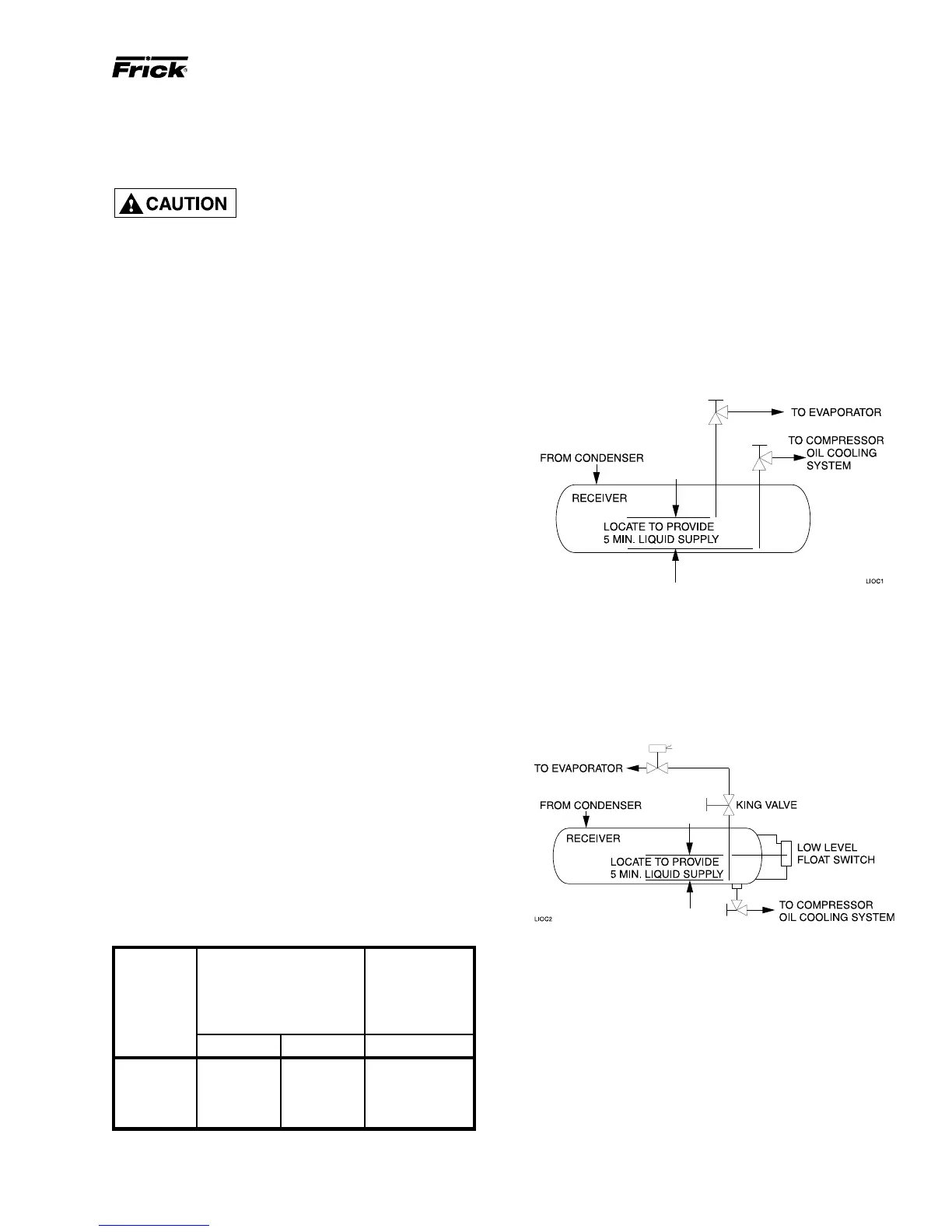

DUAL DIP TUBE METHOD

The dual dip tube method uses two dip tubes in the receiv-

er. The liquid injection tube is below the evaporator tube to

ensure continued oil cooling when the receiver level is low.

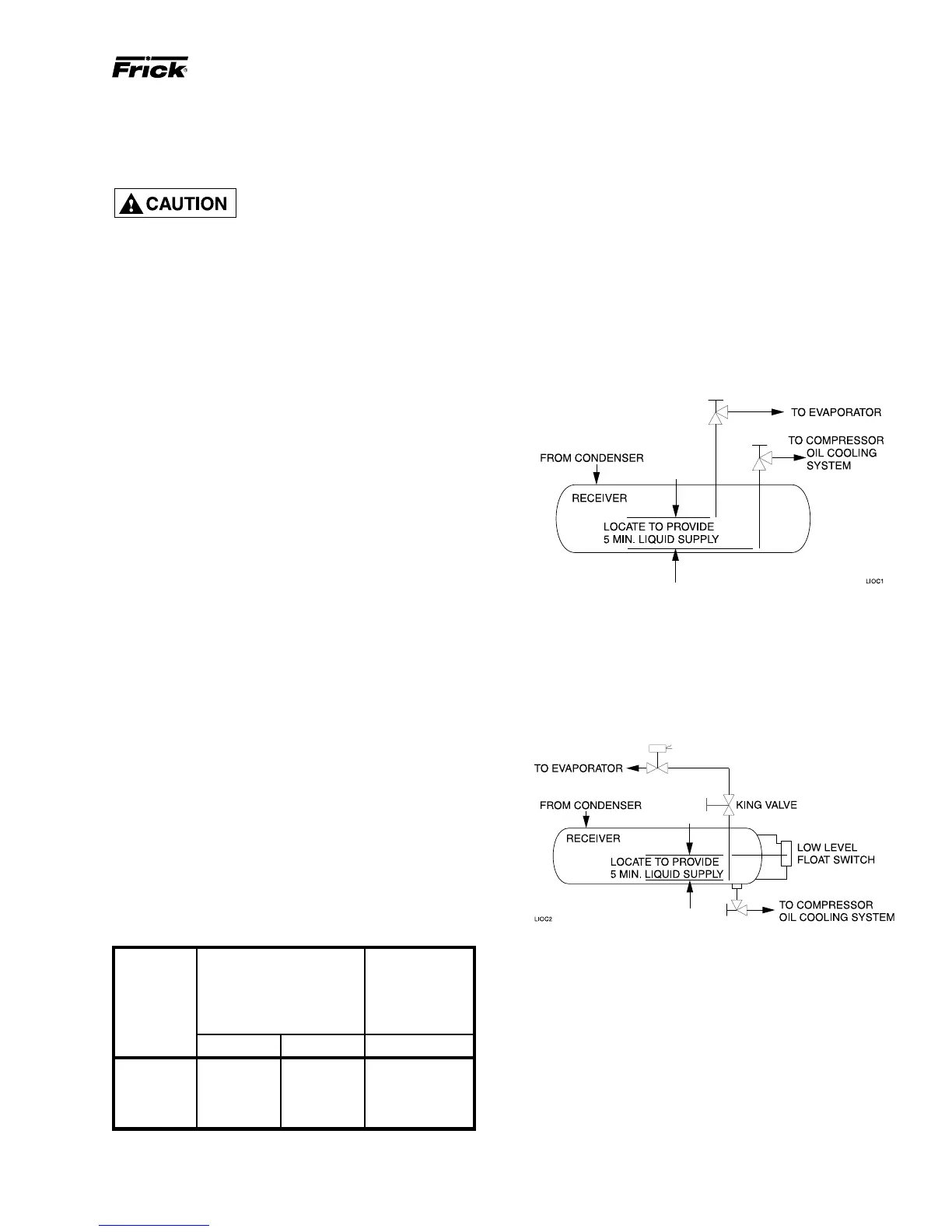

LEVEL CONTROL METHOD

The level control method utilizes a float level control on the

receiver to close a solenoid valve feeding the evaporator

when the liquid falls below that amount necessary for 5 min-

utes of liquid injection oil cooling.

start-up. Should additional heating capacity be required

because of unusual environmental condition, contact Frick

Company. The heater is energized only when the unit is not

in operation.

DO NOT ENERGIZE THE HEATER

WHEN THERE IS NO OIL IN THE

UNIT, OTHERWISE THE HEATER

WILL BURN OUT. THE OIL HEATER WILL BE ENERGIZED

WHENEVER 120 VOLT CONTROL POWER IS APPLIED

TO THE UNIT AND THE COMPRESSOR IS NOT RUNNING

UNLESS THE 10 AMP FUSE (1FU) IN THE CONTROL

PANEL IS REMOVED.

Where low compression ratios (low condensing pressures)

are anticipated, thermosyphon or water-cooled oil cooling

should be used. It is IMPERATIVE that an uninterrupted

supply of high pressure liquid refrigerant be provided to the

injection system at all times. Two items of EXTREME IM-

PORTANCE are the design of the receiver/liquid injection

supply and the size of the liquid line. It is recommended that

the receiver be oversized sufficiently to retain a 5 minute

supply of refrigerant for oil cooling. The evaporator supply

must be secondary to this consideration. Two methods of

accomplishing this are shown.

Loading...

Loading...