RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

Page 39

RECOMMENDED MAINTENANCE PROGRAM

In order to obtain maximum compressor unit performance

and ensure reliable operation, a regular maintenance pro-

gram should be followed.

The compressor unit should be checked daily for leaks, ab-

normal vibration, noise, and proper operation. A daily log

should also be maintained. There should be a continued

monitoring of oil quality and oil analysis testing. In addition,

an analysis of the unit’s vibration should be made periodi-

cally.

VIBRATION ANALYSIS

Periodic vibration analysis can be useful in detecting bear-

ing wear and other mechanical failures. If vibration analysis

is used as a part of your preventive maintenance program,

take the following guidelines into consideration:

1. Always take the vibration reading from exactly the same

places and at exactly the same percentage of load.

2. Use vibration readings taken from the new unit at start-up

as the base line reference.

3. Evaluate vibration readings carefully as the instrument

range and function used can vary. Findings can be easily

misinterpreted.

4. Vibration readings can be influenced by other equipment

operating in the vicinity or connected to the same piping as

the unit.

OIL QUALITY and ANALYSIS

High quality refrigeration oil is necessary to ensure compres-

sor longevity and reliability. Oil quality will rapidly deterio-

rate in refrigeration systems containing moisture and air or

other contaminants. In order to ensure the quality of the

refrigeration oil in the compressor unit, follow these

recommendations:

1. Only use Frick refrigeration oil as recommended by Frick

Company for your application.

2. Participate in a regular, periodic, oil analysis program to

help maintain oil and system integrity.

MOTOR BEARINGS

Follow the motor manufacturer’s maintenance recommen-

dations.

Lubricate the motor bearings prop-

erly before start-up. Maintain sub-

sequent lubrication as recom-

mended by the motor manufacturer.

OPERATING LOG: The use of an operating log, as shown on the inside back cover, permits thorough analysis of the operation

of a refrigeration system by those responsible for its maintenance and servicing. Continual recording of gauge pressures, tem-

peratures, and other pertinent information enables the observer and serviceman to be constantly familiar with the operation of

the system and to recognize immediately any deviations from normal operating conditions. It is recommended that readings be

taken at least every four hours.

MAINTENANCE

THE FACTORY INSTALLED, RECOMMENDED LUBRICANT IS LISTED ON THE MOTOR DATA PLATE. THE FOLLOWING PRODUCTS ARE DEEMED

SUITABLE LUBRICANTS UNDER NORMAL SERVICE CONDITIONS BUT MAY NOT BE CHEMICALLY COMPATIBLE OR INTERCHANGEABLE ONE

EXXON CORP. - UNIREX#2

MOBIL OIL CO. - MOBILUX#2

INTRODUCING ALTERNATES - WHEN DOUBT EXISTS, PURGE THE BEARINGS AS DESCRIBED IN THE INSTRUCTION MANUAL.

TO THE OTHER OR CORRECT FOR ALL AMBIENT OR SERVICE CONDITIONS. FOLLOW ALL MANUFACTURER'S GUIDELINES WHEN

CHEVRON OIL CO. - SRI#2

EXXON CORP. - POLYREX

SHELL OIL CO. - DOLIUM R

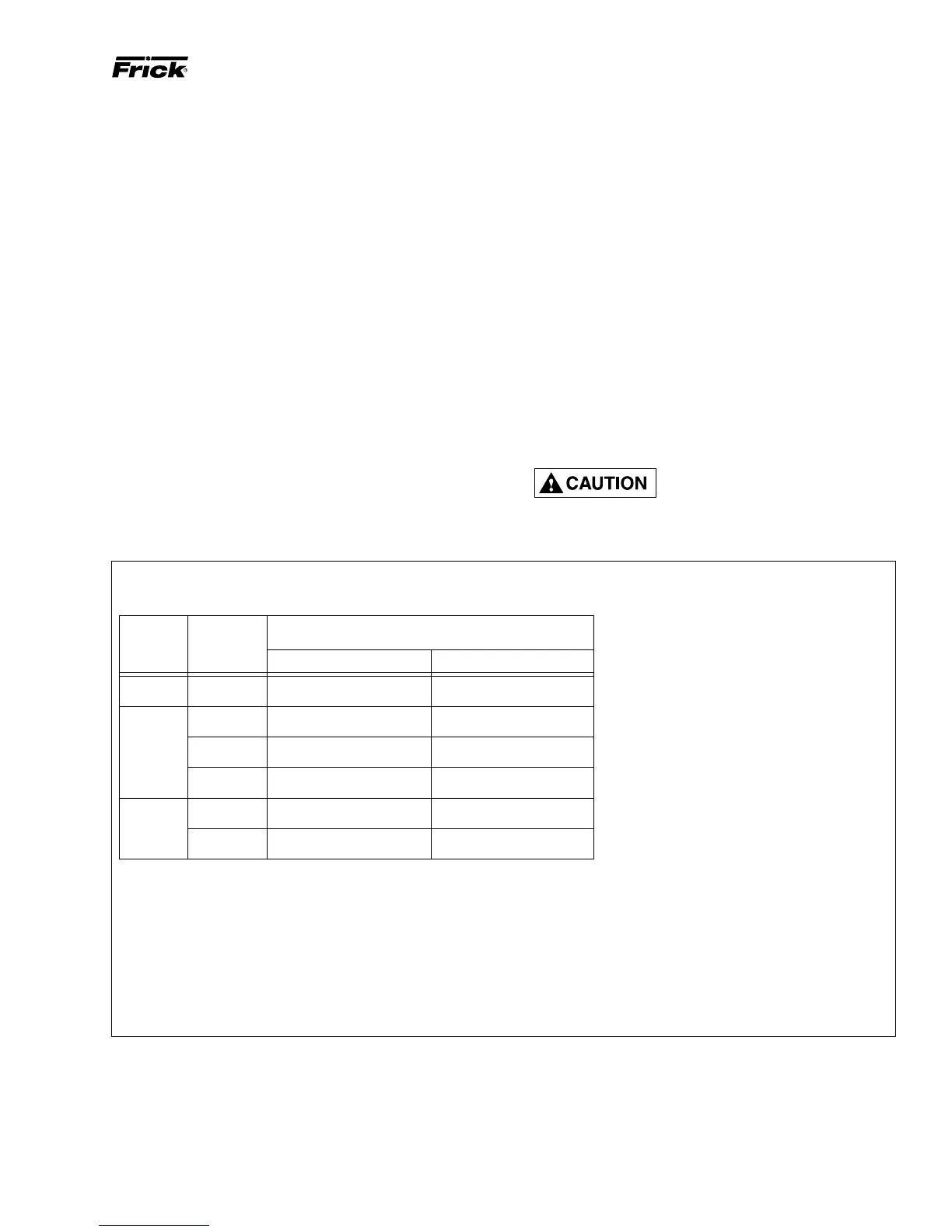

LUBRICATION SCHEDULE / INSTRUCTIONS

ENVIRONMENTAL EXTREME) = 1/3 OF THE ABOVE INTERVALS.

* LUBRICATION SCHEDULE FOR SEVERE SERVICE (VIBRATION, SHOCK AND/OR

** LUBRICATION SCHEDULE FOR ROLLER BEARINGS = 1/3 OF THE ABOVE INTERVALS.

3600

1200

360-440

5000-5800

1800

5000-5800

400-440

360

360-5800

SYNC.

RPM

FRAME

SERIES

150 DAYS (1200 HRS) 50 DAYS (1200 HRS)

390 DAYS (3120 HRS)

270 DAYS (2160 HRS)

390 DAYS (3120 HRS)

210 DAYS (1680 HRS)

270 DAYS (2160 HRS)

90 DAYS (2160 HRS)

130 DAYS (3120 HRS)

70 DAYS (1680 HRS)

90 DAYS (2160 HRS)

130 DAYS (3120 HRS)

SERVICE CYCLE* - BALL BEARING**

8 HR/DAY OPERATION 24 HR/DAY OPERATION

• REMOVE THE PIPE PLUG FROM THE

VENTING PORT OPPOSITE THE GREASE

APPLY 2 OZS. (60 GRAMS) OF GREASE

• USING A LOW PRESSURE GREASE GUN

AT EACH FITTING. DO NOT OVER GREASE.

15 MINUTES AND UNTIL ANY GREASE FLOW

THE MOTOR FOR A MINIMUM OF

• WITH THE VENT PORTS OPEN, OPERATE

HAS CEASED AT THE VENTING PORTS.

• REPLACE THE VENT PIPE PLUGS.

COVERS THAT MAY HAVE BEEN REMOVED

• REPLACE ANY AND ALL GUARDS AND

• REMOVE POWER.

TO ACCESS THE MOTOR.

FITTING.

• LUBRICATE BEARINGS WITH POWER IN

• CLEAR AND CLEAN THE GREASE FITTINGS

AND SURROUNDING AREA.

THE OFF CONDITION.

Loading...

Loading...