RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

Page 8

INSTALLATION

HOT ALIGNMENT OF COMPRESSOR/MOTOR

Hot alignments can only be made after the unit has oper-

ated for several hours and all components are at operating

temperatures.

Shut down the unit and quickly affix dial indicator to cou-

pling motor hub, then take readings of both the face and rim

of the compressor hub. If these readings are within toler-

ance, record reading, attach coupling guard, and restart unit.

However, if the reading is not within limits, compare the hot

reading with the cold alignment and adjust for this differ-

ence; i.e. if the rim at 0

O

and 180

O

readings indicates that

the motor rises .005" between its hot and cold state, .005"

of shims should be removed from under the motor.

After the initial hot alignment adjustment is made, restart

unit and bring to operating temperature. Shut down and re-

check hot alignment. Repeat procedure unit hot alignment

is within specified tolerance.

INSTALL COUPLING GUARD BE-

FORE OPERATING COMPRES-

SOR.

CHECKING MOTOR/COMPRESSOR

ROTATION

COMPRESSOR ROTATION IS CLOCKWISE WHEN FAC-

ING THE END OF THE COMPRESSOR SHAFT. Under NO

conditions should the motor rotation be checked with the

coupling center installed as damage to the compressor may

result.

HOLDING CHARGE AND STORAGE

Each compressor unit is pressure and leak tested at the

Frick factory and then thoroughly evacuated and charged

with dry nitrogen to ensure the integrity of the unit during

shipping and short term storage prior to installation.

NOTE: Care must be taken when entering the unit to

ensure that the nitrogen charge is safely released.

All units must be kept in a clean, dry location to prevent

corrosion damage. Reasonable consideration must be given

to proper care for the solid state components of the micro-

processor. Unit which will be stored for more than two

months must have the nitrogen charge checked peri-

odically.

COMPRESSOR

COMPRESSOR UNIT OIL

DO NOT MIX OILS of different

brands, manufacturers, or types.

Mixing of oils may cause excessive

oil foaming, nuisance oil level cutouts, oil pressure loss,

gas or oil leakage and catastrophic compressor failure.

Use of oils other than Frick Oil must

be approved in writing by Frick en-

gineering or warranty claim may be

denied.

Use of filter elements other than

Frick must be approved in writing

by Frick engineering or warranty

claim may be denied.

The oil charge shipped with the unit is the best suited lubri-

cant for the conditions specified at the time of purchase. If

there is any doubt due to the refrigerant, operating pres-

sures, or temperatures; refer to Frick Pub. E160-802 SPC

for guidance.

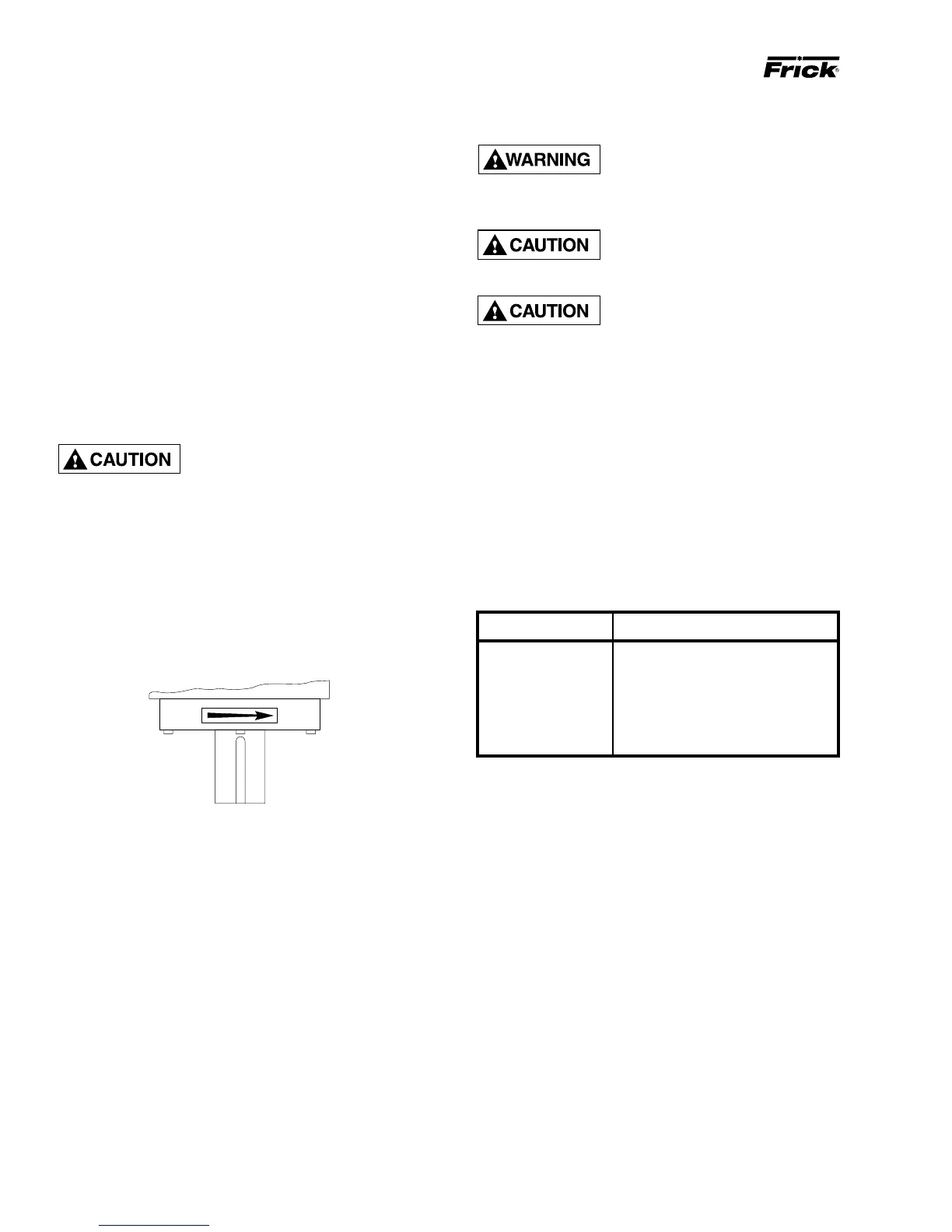

OIL CHARGE

The normal charging level is midway in the top sight glass

located midway along the oil separator shell. Normal oper-

ating level is between the top sight glass and bottom sight

glass. The following table gives the approximate oil charge

quantity.

TABLE - BASIC OIL CHARGE (Gal)

MODEL BASIC CHARGE* (GAL.)

12 10

15 10

19 14

24 14

30 17

39 17

50 21

* Add oil volume for external oil cooler, according to cooler

size selected: 6 x 5 TSOC - 4 gal.; 6 x 5 WCOC - 5 gal.; 8 x

5 TSOC - 6-1/2 gal.; and 8 x 5 WCOC - 8 gal.

Add oil by attaching the end of a suitable pressure type

hose to the oil charging valve, located on the top of the oil

separator on the compressor end of the separator. Using a

pressure-type pump and the recommended Frick oil, open

the charging valve and pump oil into the separator.

Oil distillers and similar equipment which act to trap oil must

be filled prior to unit operation to normal design outlet lev-

els. The same pump used to charge the unit may be used

for filling these auxiliary oil reservoirs.

NOTE: The sight glass, located near the bottom of the

separator shell at the discharge end, should remain

empty when the unit is in operation. The presence of oil

in this end of the vessel during operation indicates liq-

uid carryover or malfunction of the oil return.

OIL HEATER

Standard units are equipped with a 500 watt oil heater, pro-

viding sufficient heat to maintain the oil temperature for most

indoor applications during shutdown cycles to permit safe

Loading...

Loading...