RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

Page 7

PARALLEL ALIGNMENT

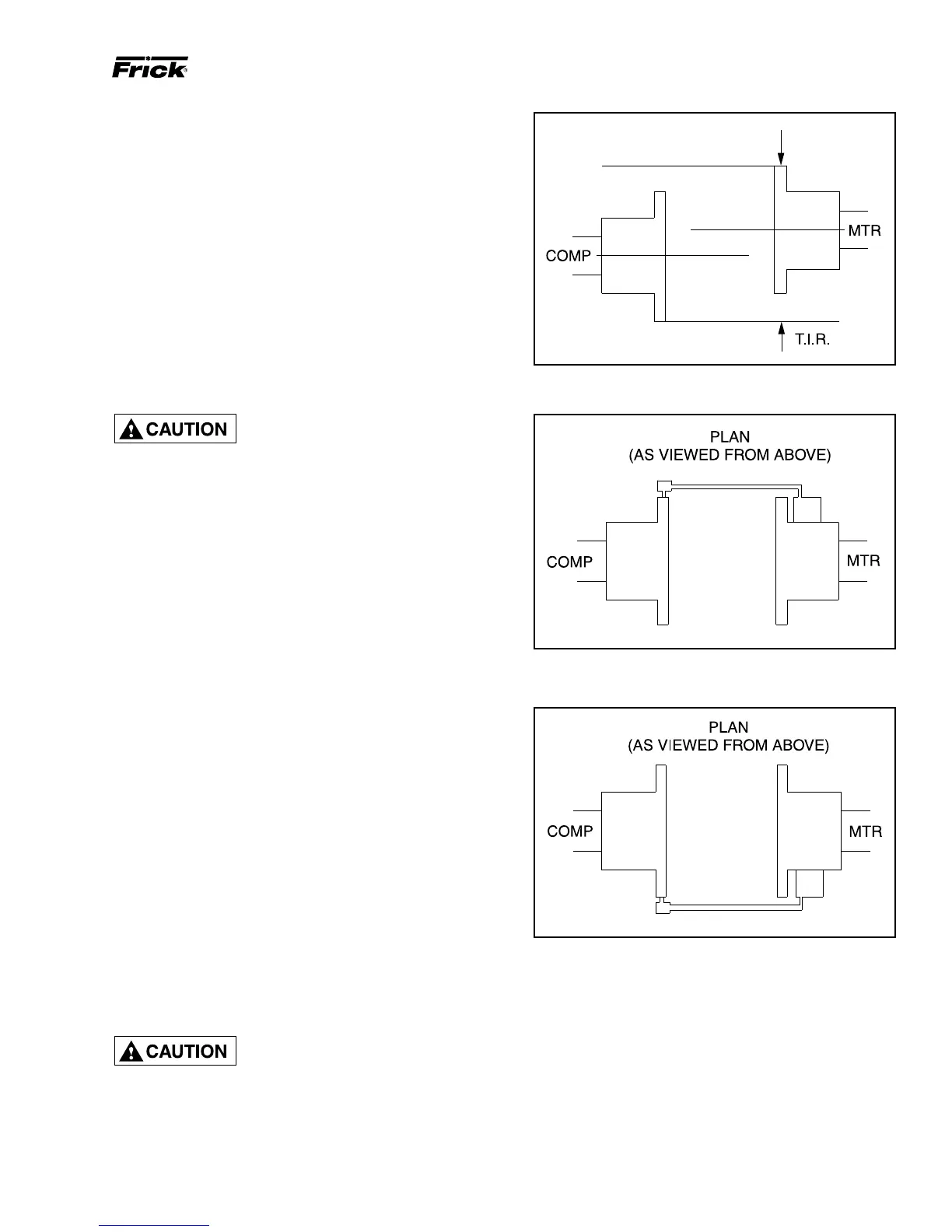

6. To check parallel alignment, as shown in Fig. 4, reposi-

tion dial indicator so the stem is in contact with the rim of the

compressor hub, as shown in Fig. 5.

Check the dial indicator to be sure that the indicator stem is

slightly loaded so as to allow movement in both directions.

7. Check parallel height misalignment by setting dial indica-

tor at zero when viewed at the 12 o'clock position. Rotate

both coupling hubs together 180

O

(6 o'clock position). At this

position the dial indicator will show TWICE the amount of

parallel height misalignment.

8. Loosen motor anchor bolts and add or remove shims under

the four motor feet until parallel height misalignment is within

specified tolerance when anchor bolts are retightened.

CARE MUST BE USED WHEN

CORRECTING FOR PARALLEL

MISALIGNMENT TO ENSURE

THAT THE AXIAL SPACING AND ANGULAR MISALIGN-

MENT IS NOT SIGNIFICANTLY DISTURBED.

9. After the parallel height misalignment is within tolerance,

repeat Steps 1 through 5 until angular misalignment is within

specified tolerance.

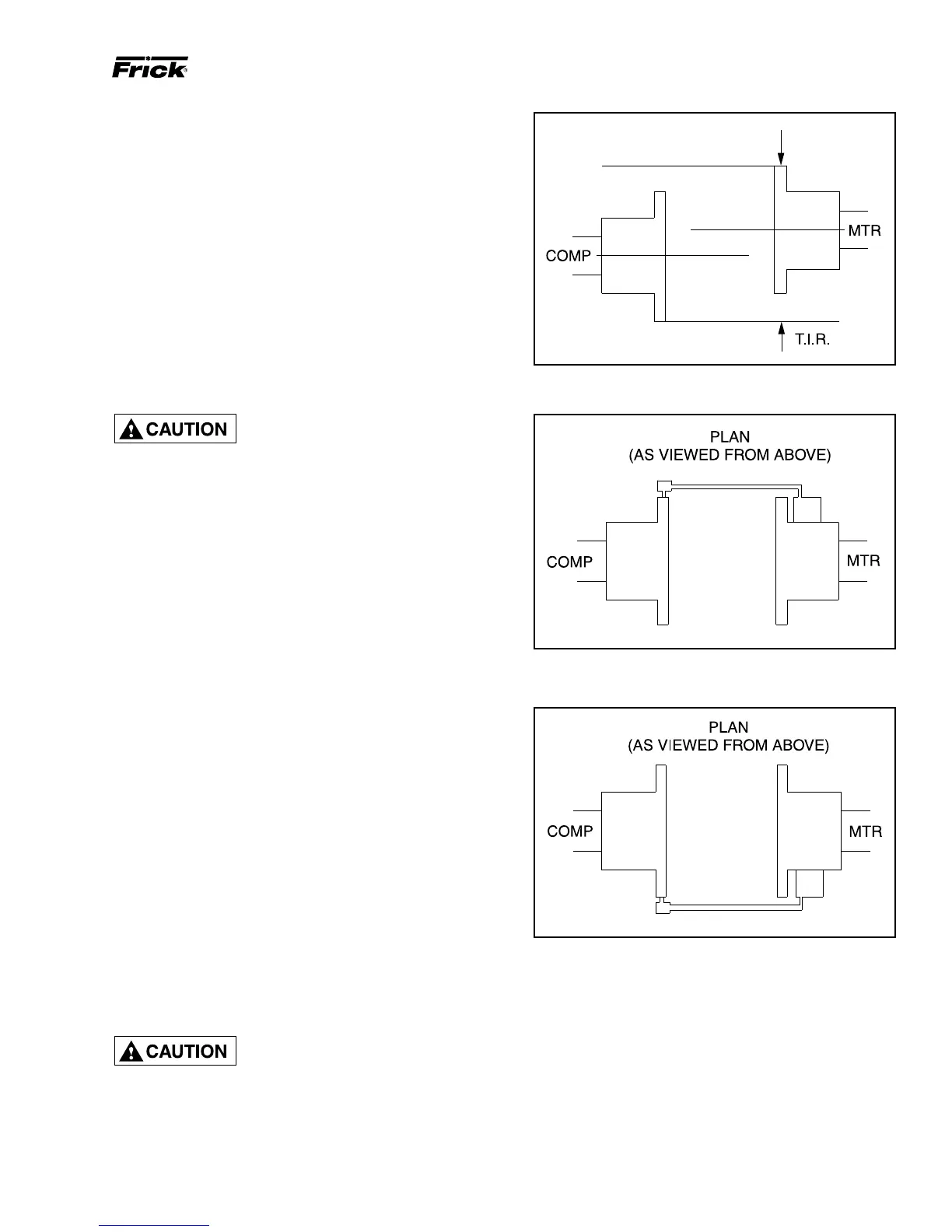

10. Check parallel lateral misalignment by positioning dial

indicator so the stem is in contact with the rim of the com-

pressor hub at 3 o'clock, as shown in Fig. 6.

Set indicator at zero and rotate both coupling hubs together

180

O

(9 o'clock position), as shown in Fig. 5.

Adjust parallel lateral misalignment using the motor adjust-

ing screws until reading is within specified tolerance.

11. Recheck angular misalignment and realign if necessary.

12. Tighten motor anchor bolts and rotate both coupling hubs

together, checking the angular and parallel misalignment

through the full 360

O

travel at 90

O

increments. If dial read-

ings are in excess of specified tolerance, realign as required.

13. When the coupling hubs have been aligned to within

specified tolerance, a recording of the cold alignment must

be made for unit records and usage during hot alignment.

14. Bump the motor to check for correct compressor rota-

tion. COMPRESSOR ROTATION IS CLOCKWISE WHEN

FACING COMPRESSOR SHAFT (see "CHECKING MO-

TOR/COMPRESSOR ROTATION", page 8). After verifica-

tion, install gear or disk drive spacer, as applicable.

15. Install the coupling guard before operating the compres-

sor.

When installing drive spacer, make

sure that hub spacing is within lim-

its shown on the Coupling Data

Table applicable to the coupling being installed and that

the clamping bolt(s) are properly torqued.

FIG. 4 - PARALLEL MISALIGNMENT

FIG. 5 - DIAL INDICATOR ATTACHED (AT 9 O'CLOCK)

FIG. 6 - DIAL INDICATOR AT 3 O'CLOCK

INSTALLATION

Loading...

Loading...