RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

Page 31

OPERATION

COMPRESSOR HYDRAULIC SYSTEM

The compressor hydraulic system moves the movable slide

valve (MSV) to load and unload the compressor. It also

moves the movable slide stop (MSS) to increase or decrease

the compressor’s volume ratio (Vi).

CAPACITY CONTROL

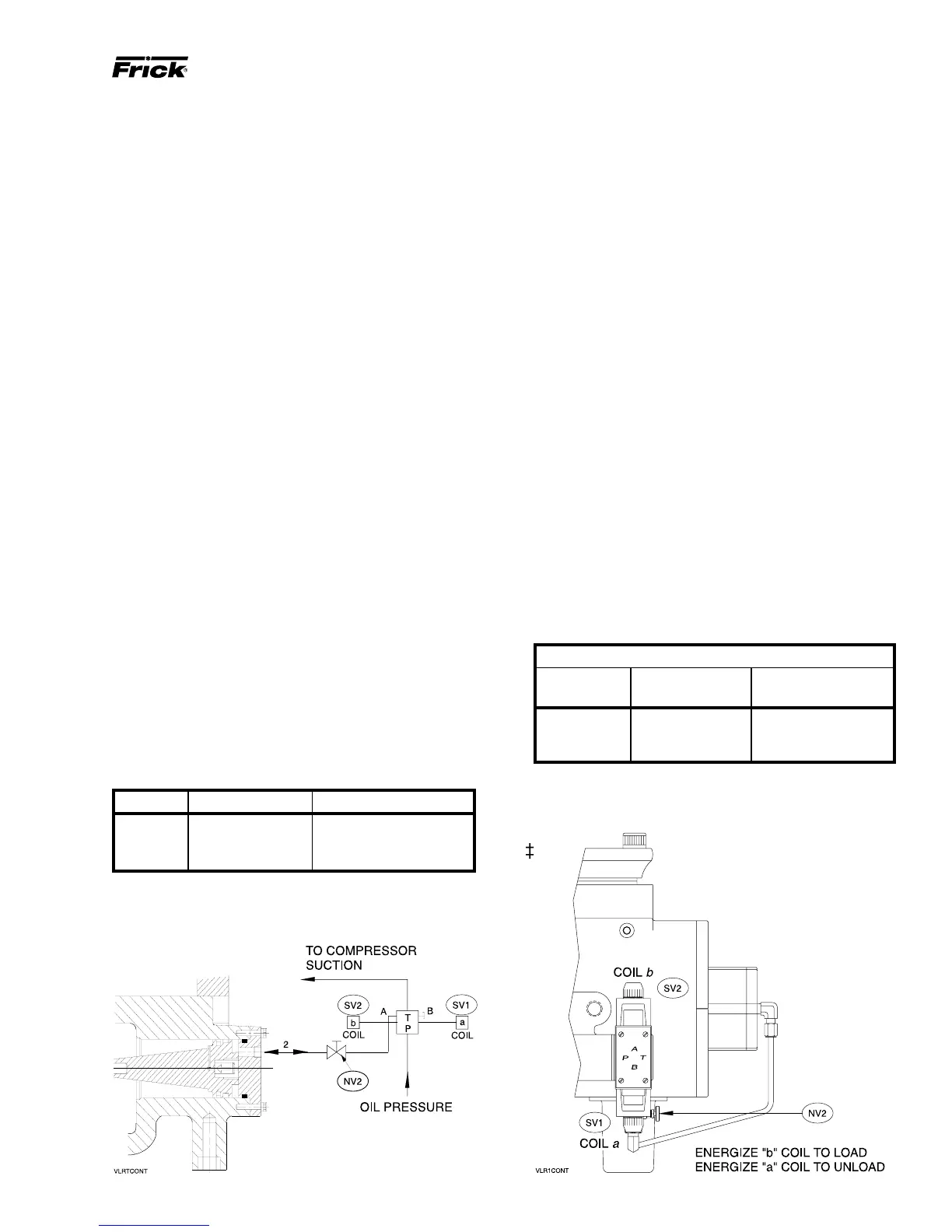

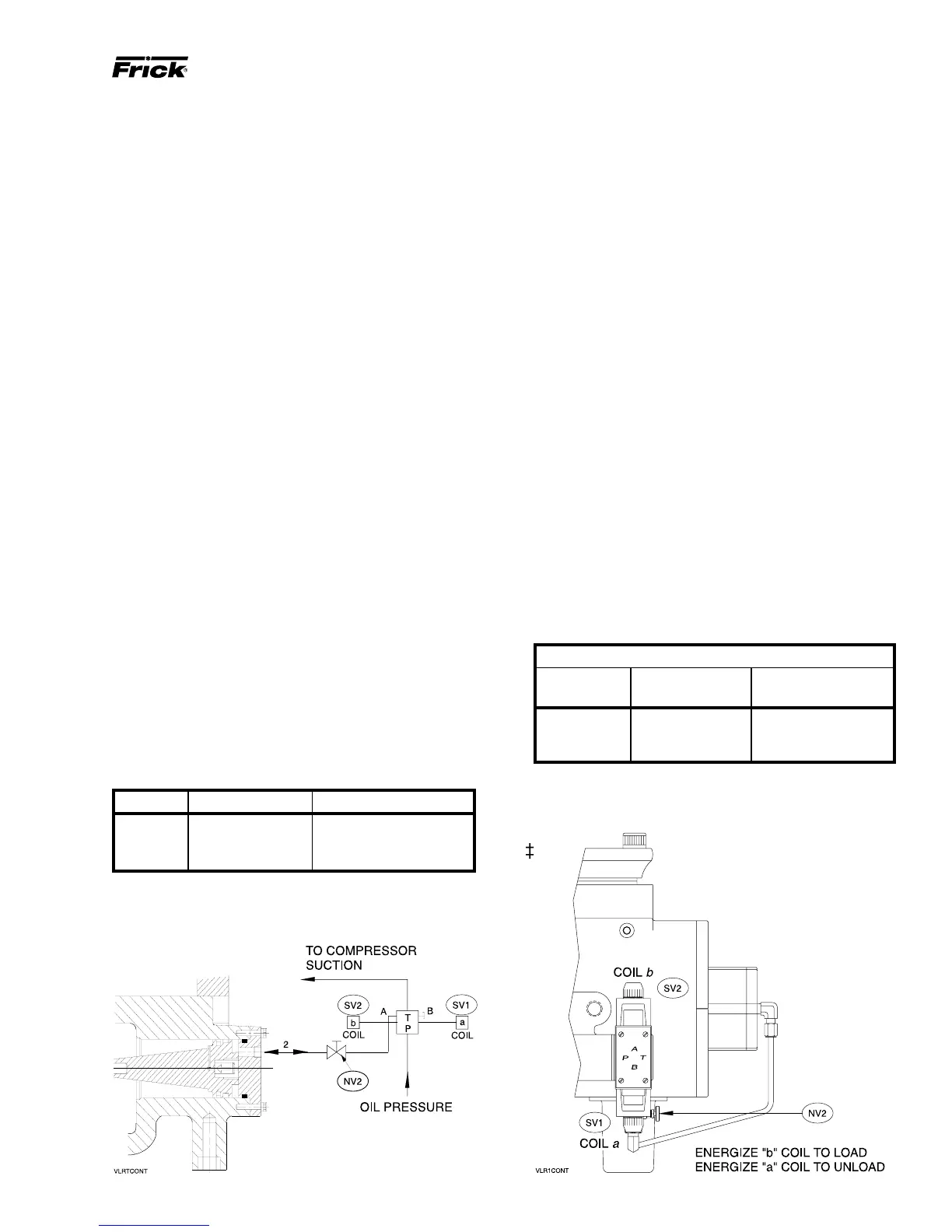

COMPRESSOR LOADING: If the capacity control valve is

mounted on the base, the compressor loads when MSV so-

lenoid coil SV1 is energized. If the capacity control valve is

mounted on the compressor, the compressor loads when

MSV solenoid coil SV2 is energized. Oil flows from the sole-

noid valve through the needle valve (NV2) to compressor

port 2, where it enters the load side of the slide valve piston.

This equalizes the force on the slide valve piston and dis-

charge pressure on the slide valve area loads the compressor.

COMPRESSOR UNLOADING: If the capacity control valve

is mounted on the base, the compressor unloads when MSV

solenoid SV2 is energized. If the capacity control valve is

mounted on the compressor, the compressor unloads when

MSV solenoid coil SV2 is energized. Oil is allowed to flow

from compressor port 2 through the needle valve to the MSV

solenoid. This allows discharge pressure on the slide valve

piston to unload the slide valve as the piston moves outward.

ADJUSTMENT (Capacity Control): A needle valve (NV2)

is provided to adjust slide valve travel time, preventing ex-

cessive slide valve “hunting”. NV2 should be adjusted to

restrict oil flow to compressor port so that slide valve travel

time from full load to full unload, or vice versa is a minimum

of 30 seconds.

NOTE: A change in operating conditions may require

readjustment of Slide Valve travel time (NV).

VOLUMIZER

®

II Vi CONTROL

Solenoid valves 3 and 4 control the Vi Ratio. Oil is internally

ported to move the Movable Slide Stop.

Vi SOL-3 (TOP) SOL-4 (BOTTOM)

2.2 Energized Energized

3.5 De-energized Energized

5.0 De-energized De-energized

CAPACITY CONTROL VALVE MOUNTED ON BASE

FUNCTIONAL CHECK OF THE COMPRESSOR

VOLUME RATIO CONTROL (Vi) OPERATION

1. Remove the slide valve potentiometer cover located on

the outlet end of the compressor and secured by 4 cap

screws.

2. Push the Slide Stop Manual 2.2 Vi key on the micro keypad.

3. Push Manual Load on the Slide Valve Control and hold in

the depressed position until the compressor is fully loaded.

4. Remove the Capacity Position Potentiometer which is

secured by 2 bolts. This will expose the indicator rod which

protrudes from the indicator rod guide.

5. In the 2.2 Vi position, the rod should extend from the

guide the amount shown in the Indicator Rod Extension

table.

6. With the slide valve fully loaded, depress the manual 3.5

Vi key. Movement of the indicator rod should occur as the

Vi is changed so that the rod extension corresponds to the

table.

7. Reassemble the parts if the functional check is satisfac-

tory.

If the indicator rod does not move to the proper position as

the table indicates, then the compressor is not changing Vi

in either manual or optional automatic operation. This would

result in higher compressor motor horsepower consump-

tion and possibly high oil temperature. The problem would

be caused by a malfunction of either solenoid valve 3SOL

or 4SOL, or the solenoid coil. Replace as required.

INDICATOR ROD EXTENSION (in.)

Vi RXB RXB

POSITION 12, 15, & 19 24, 30, 39, & 50

2.2 .412 / .454 .434 / .474

3.5 .297 / .339 .319 / .359

5.0 .235 / .277 .258 / .298

CAPACITY CONTROL VALVE ON COMPRESSOR

Loading...

Loading...