RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

Page 5

INSTALLATION

MAXIMUM

TOTAL

INDICATOR

READING

CLAMP

BOLT

TORQUE

KEYWAY

SETSCREW

TORQUE

BETWEEN SHAFT SPACING

SHAFT ENGAGEMENT

FACE SPACING

CH

COUP-

LING

SIZE in. mm mm mmin. in. mm in. in. mm in. mm ft-lb Nm ft-lb Nm

COUPLING HUB

MIN *

MAX

MIN MAX

CH COUPLING DATA TABLE

76.2

76.2

96.8

90.5

101.6

138.1

161.9

149.2

23.8

34.9

46.0

60.3

19.0

25.4

25.4

31.8

22.2

27.0

28.6

36.5

3

3

3-13/16

3-9/16

3/4

1

1

1-1/4

15/16

1-3/8

1-13/16

2-3/8

7/8

1-1/16

1-1/8

1-7/16

.004

.004

.004

.004

.104

.104

.104

.104

10

20

35

35

13.6

27.1

47.5

47.5

13

13

13

13

17.6

17.6

17.6

17.6

3-1/4

3-7/16

4

5-7/16

6

7

8

9C

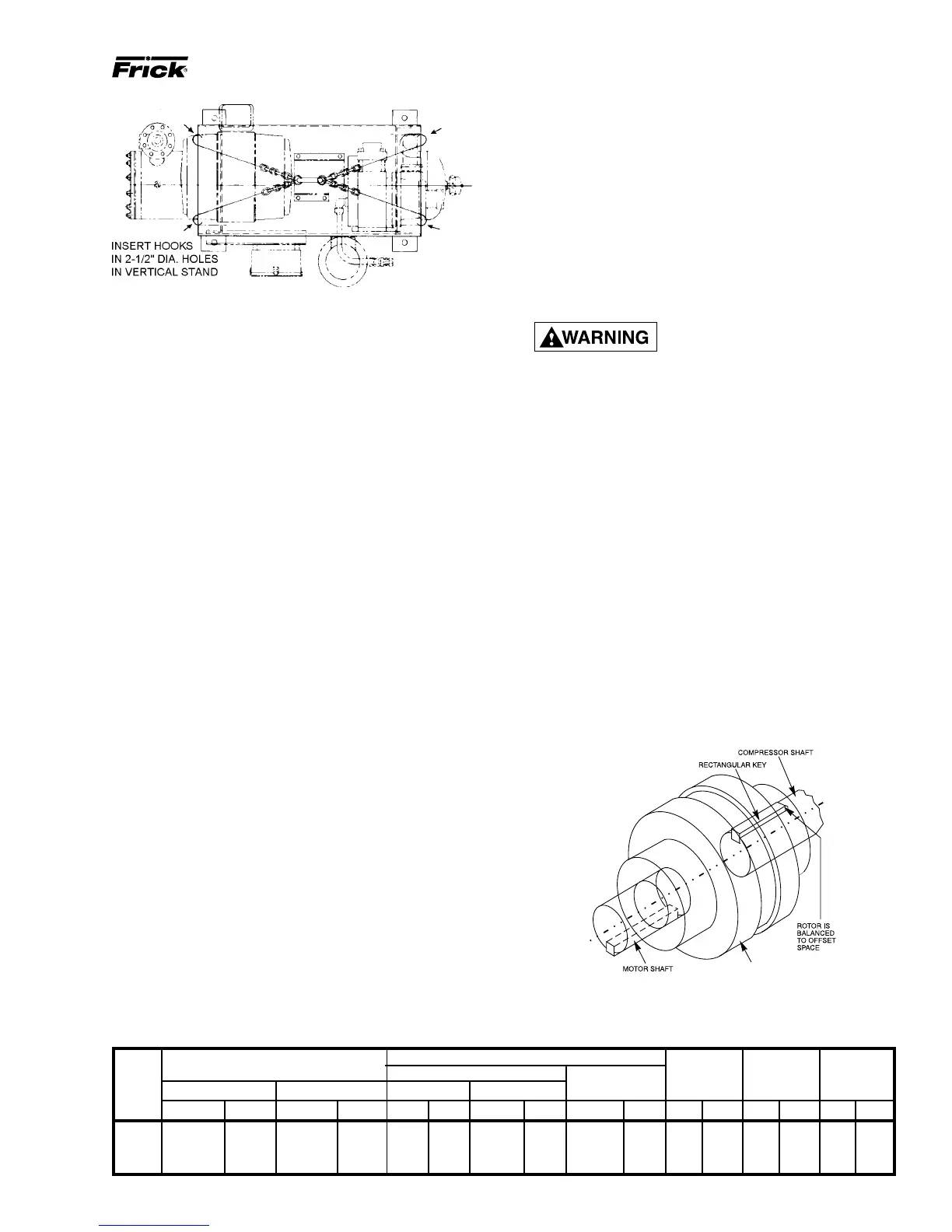

FIG. 2 - ALTERNATIVE LIFTING METHOD

The unit can be moved with a forklift by forking under the

skid, or it can be skidded into place with pinch bars by push-

ing against the skid. NEVER MOVE THE UNIT BY PUSH-

ING OR FORKING AGAINST THE SEPARATOR SHELL

OR ITS MOUNTING SUPPORTS.

SKID REMOVAL

If the unit is rigged into place the skid can be removed by

taking off the nuts and bolts that are fastening the unit mount-

ing supports to the skid before lowering the unit onto the

mounting surface.

If the unit is skidded into place, remove the cross members

from the skid and remove the nuts anchoring the unit to the

skid. Using a 5-ton jack under the separator, raise the unit at

the compressor end until it clears the two mounting bolts.

Spread the skid to clear the unit mounting support, then lower

the unit to the surface. Repeat procedure on opposite end.

MOTOR MOUNTING

The following procedure is required only when the motor is

mounted at the job site.

1. Thoroughly clean the motor feet and mounting pads of

grease, burrs, and other foreign matter to ensure firm seat-

ing of the motor.

2. Attach the motor to the base using the bolts and motor-

raising blocks, if required. Bolt snugly through the base.

3. Weld the four kick bolts into place so that they are posi-

tioned to allow movement of the motor feet.

4. Now that the motor has been set, check that the shafts

are properly spaced for the coupling being used. Refer to

the coupling data table for the applicable dimension.

COMPRESSOR/MOTOR COUPLING

INSTALLATION

RXB PLUS units are arranged for direct motor drive and

require a flexible drive coupling to connect the compressor

to the motor. Before installing, perform the following:

1. Inspect the shaft of the motor and compressor to ensure

that no nicks, grease, or foreign matter is present.

2. Inspect the bores in the coupling hubs to make sure that

they are free of burrs, dirt, and grit.

3. Check that the keys fit the hubs and shafts properly.

CH COUPLING – The T.B. Woods Elastomeric CH Coupling

is used in most applications. It consists of two drive hubs

and a loose, gear-type Hytrel Drive Spacer. The split hub is

clamped to the shaft by tightening the clamp screws. Torque

is transmitted from the motor through the elastomeric gear

which floats freely between the hubs. Install as follows:

IT IS MANDATORY THAT THE COU-

PLING CENTER BE REMOVED

AND THE DIRECTION OF MOTOR

ROTATION BE CONFIRMED

BEFORE

RUNNING THE

COMPRESSOR. Proper rotation of the compressor shaft

is clockwise looking at the end of the compressor shaft.

FAILURE TO FOLLOW THIS STEP COULD RESULT IN

BACKWARD COMPRESSOR ROTATION WHICH CAN

CAUSE COMPRESSOR FAILURE OR EXPLOSION OF

THE SUCTION HOUSING.

1. Slide one hub onto each shaft as far as possible. It may

be necessary to use a screwdriver as a wedge in the slot to

open the bore before the hubs will slide onto the shafts.

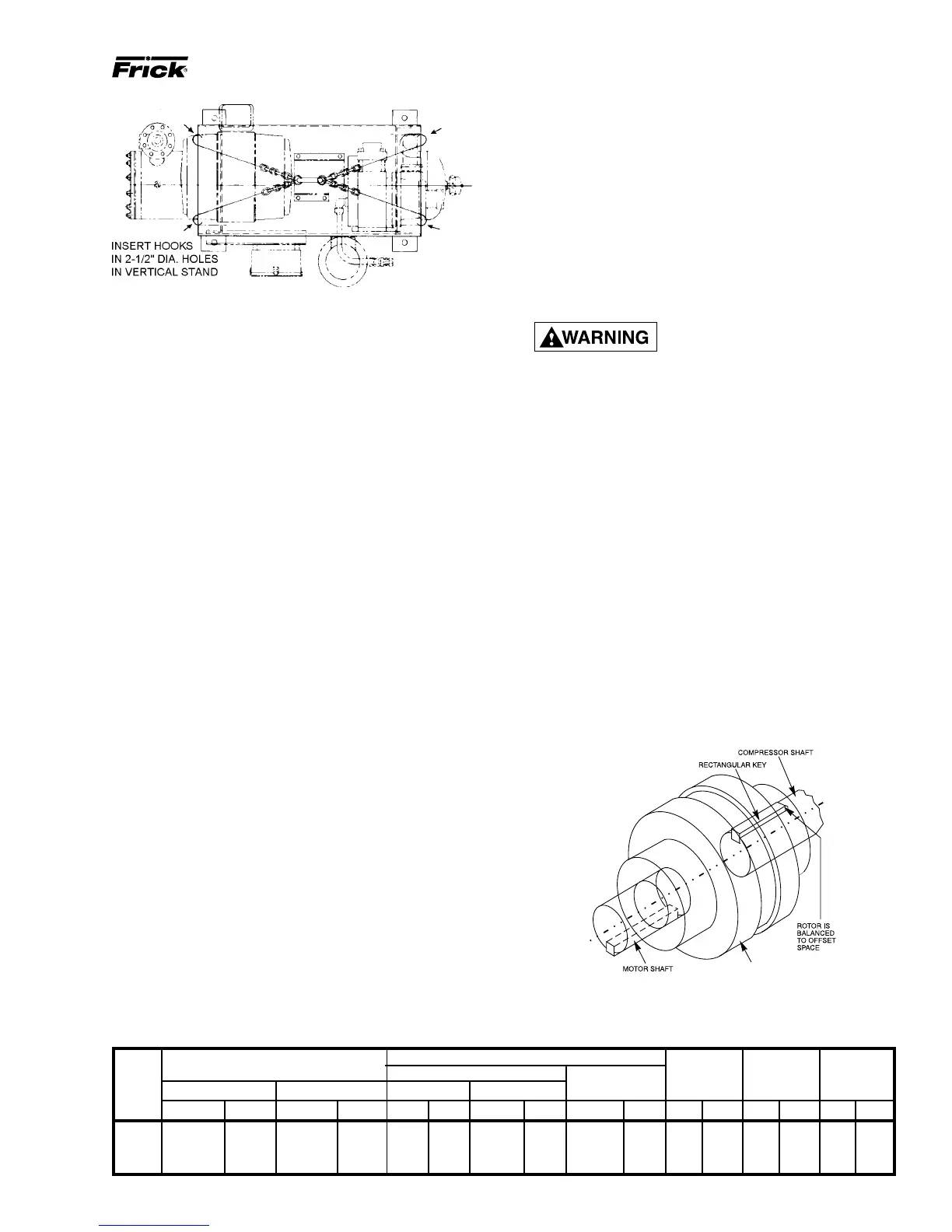

2. Hold the elastomeric gear between the hubs and slide

both hubs onto the gear to fully engage the mating teeth.

Make sure that the keys on the compressor and motor halves

of the coupling are offset 180

O

(see FIG. 3). Center the gear

and hub assembly so there is equal engagement on both

shafts. Adjust the space between hubs as specified in the

CH Coupling Data Table below.

3. Torque the clamping bolts in both hubs to the torque value

given in the CH Data Table. DO NOT USE ANY LUBRI-

CANT ON THESE BOLTS.

4. Proceed to Coupling Alignment.

DRIVE COUPLING

FIG. 3 - COUPLING/SHAFT KEYS INSTALLATION

Loading...

Loading...