RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

Page 12

INSTALLATION

ECONOMIZER - HIGH STAGE (OPTIONAL)

The economizer option provides an increase in system ca-

pacity and efficiency by subcooling liquid from the condenser

through a heat exchanger or flash tank before it goes to the

evaporator. The subcooling is provided by flashing liquid in

the economizer cooler to an intermediate pressure level.The

intermediate pressure is provided by a port located part way

down the compression process on the screw compressor.

As the screw compressor unloads, the economizer port will

drop in pressure level, eventually being fully open to suc-

tion. Because of this, an output from the microprocessor is

generally used to turn off the supply of flashing liquid on a

shell and coil or DX economizer when the capacity falls be-

low approximately 45%-60% capacity (85%-90% slide valve

position). This is done because the compressor will be more

efficient operating at a higher slide valve position with the

economizer turned off, than it will at a low slide valve posi-

tion with the economizer turned on. Please note however

that shell and coil and DX economizers can be used at low

compressor capacities in cases where efficiency is not as

important as ensuring that the liquid supply is subcooled. In

such cases, the economizer liquid solenoid can be pro-

grammed to be left open whenever the compressor is run-

ning.

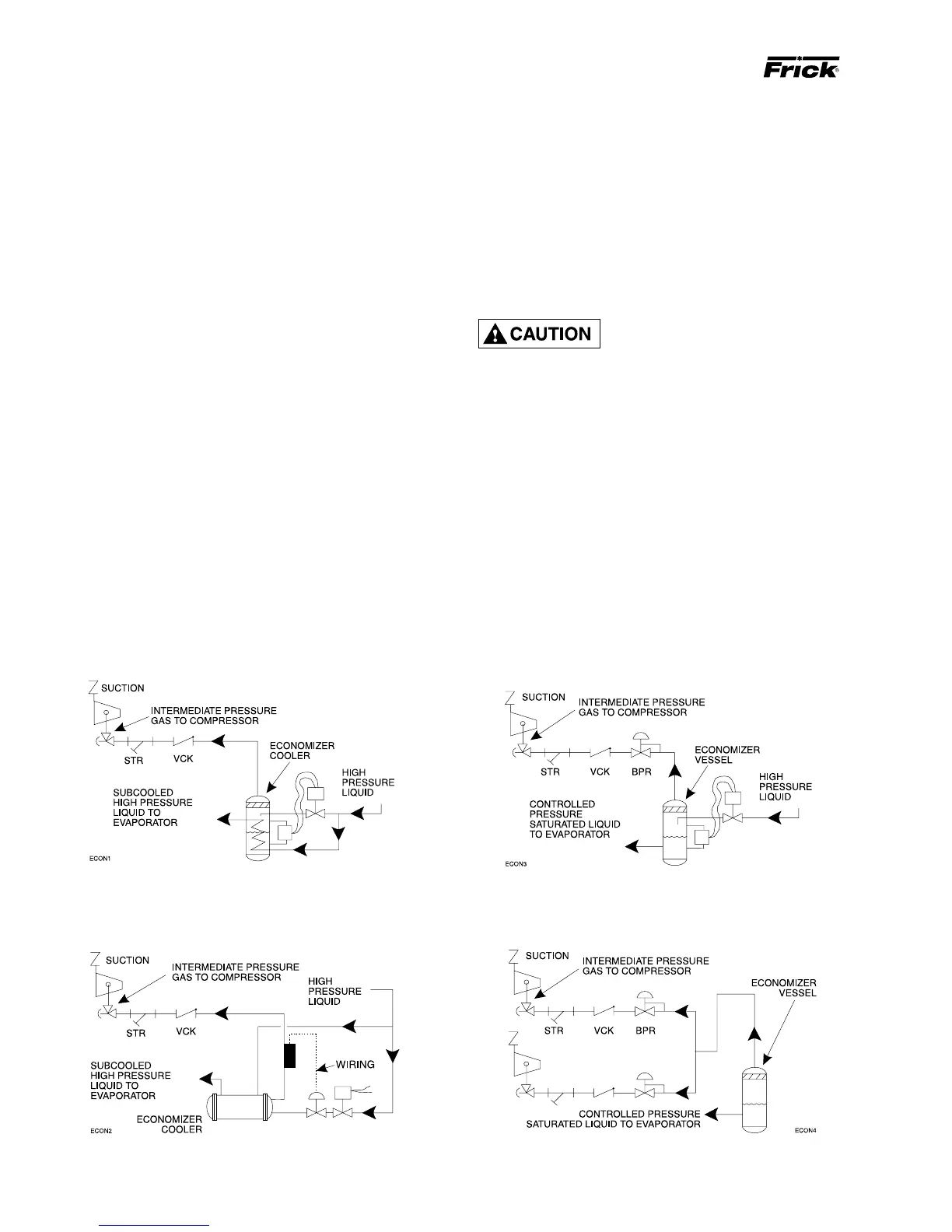

Due to the tendency of the port pressure to fall with de-

creasing compressor capacity, a back-pressure regulator

valve (BPR) is generally required on a flash economizer

system (FIG. 3) in order to maintain some preset pressure

difference between the subcooled liquid in the flash vessel

and the evaporators. If the back-pressure regulator valve is

not used on a flash economizer, it is possible that no pres-

sure difference will exist to drive liquid from the flash vessel

to the evaporators, since the flash vessel will be at suction

pressure. In cases where wide swings in pressure are an-

ticipated in the flash economizer vessel, it may be neces-

sary to add an outlet pressure regulator to the flash vessel

outlet to avoid overpressurizing the economizer port, which

could result in motor overload. Example: A system feeding

liquid to the flash vessel in batches.

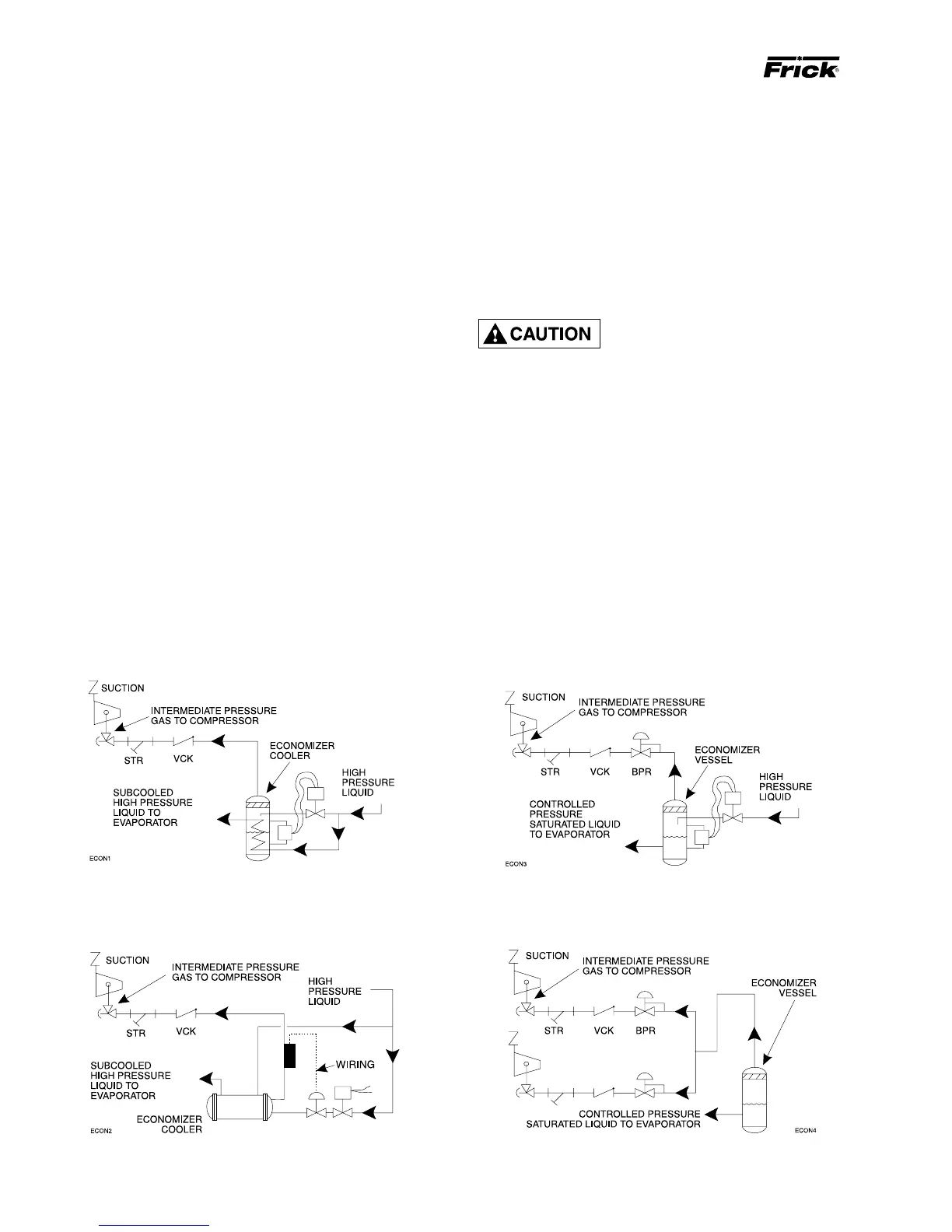

The recommended economizer systems are shown below.

Notice that in all systems there should be a strainer (STR)

and a check valve (VCK) between the economizer vessel

and the economizer port on the compressor. The strainer

prevents dirt from passing into the compressor and the check

valve prevents oil from flowing from the compressor unit to

the economizer vessel during shutdown.

Other than the isolation valve

needed for strainer cleaning, it is

essential that the strainer be the

last device in the economizer line before the compres-

sor. Also, piston-type check valves are recommended

for installation in the economizer line, as opposed to

disc-type check valves. The latter are more prone to gas-

pulsation-induced failure. The isolation and check val-

ves and strainer should be located as closely as pos-

sible to the compressor, preferably within a few feet.

For refrigeration plants employing multiple compressors on

a common economizing vessel, regardless of economizer

type, each compressor must have a back-pressure regulat-

ing valve in order to balance the economizer load, or gas

flow, between compressors. The problem of balancing load

becomes most important when one or more compressors

run at partial load, exposing the economizer port to suction

pressure. In the case of a flash vessel, there is no need for

the redundancy of a back-pressure regulating valve on the

vessel and each of the multiple compressors. Omit the BPR

valve on the flash economizer vessel and use one on each

compressor, as shown in FIG. 4.

FIG. 2 - DIRECT EXPANSION ECONOMIZER SYSTEM

FIG. 1 - SHELL and COIL ECONOMIZER SYSTEM

FIG. 4 -MULTIPLE COMPRESSOR ECONOMIZER SYSTEM

FIG. 3- FLASH ECONOMIZER SYSTEM

Loading...

Loading...