RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

Page 43

TROUBLESHOOTING FRICK SBC MICROPROCESSOR SYSTEM (Continued)

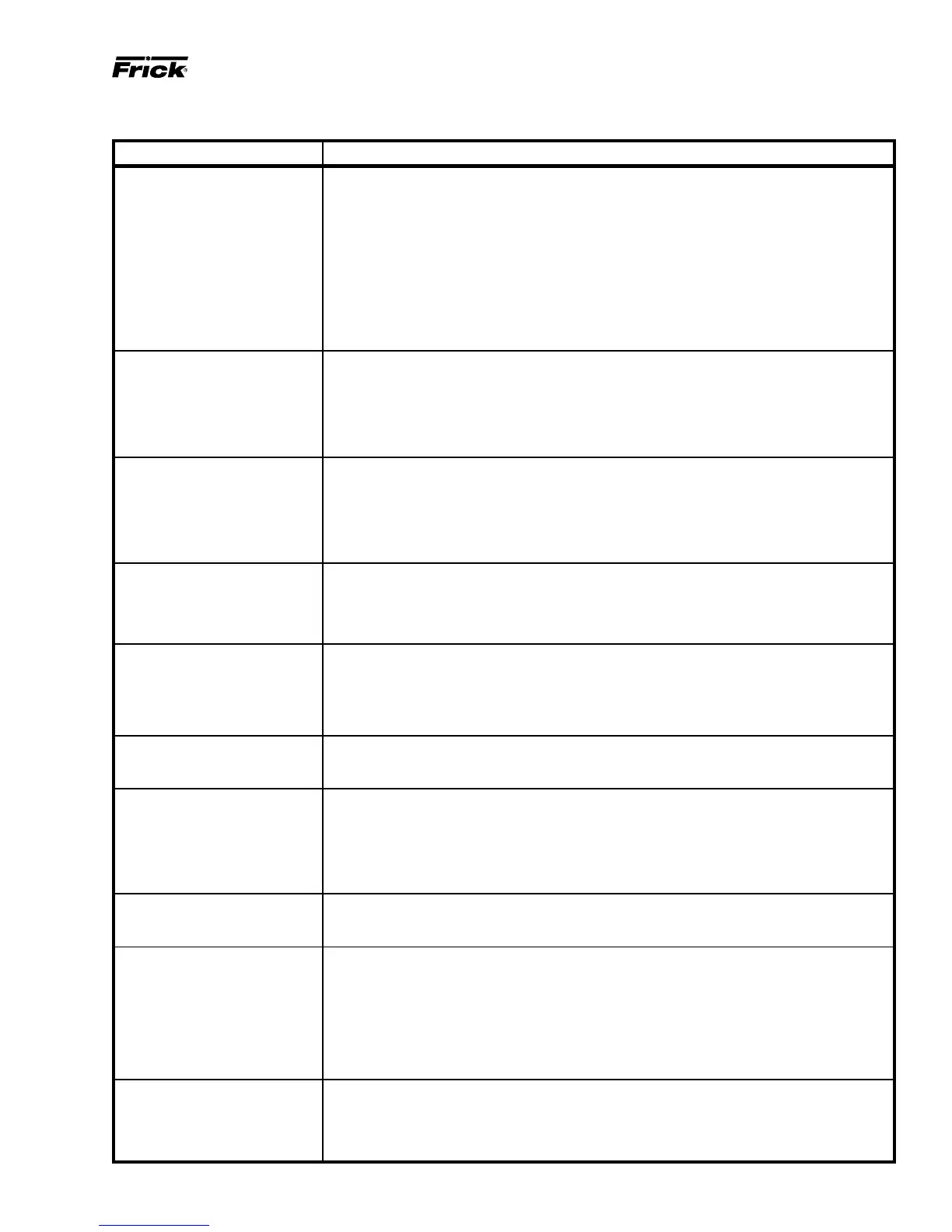

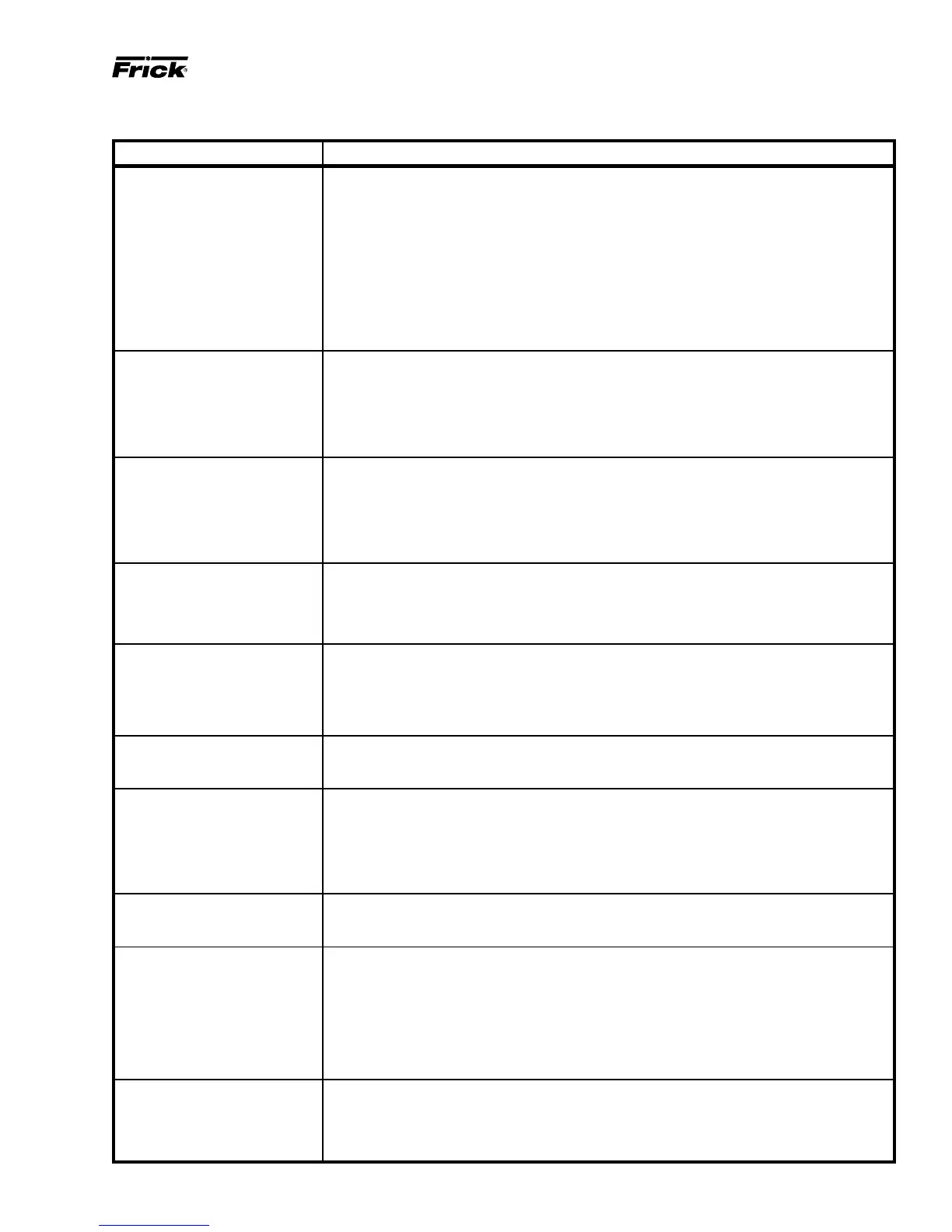

SYMPTOM PROBABLE CAUSES and CORRECTIONS

SLIDE VALVE DOES NOT LOAD Verify that the Slide Valve is in the AUTO mode and that capacity control is calling for loading

and/or UNLOAD or unloading (AUTO L or AUTO U will appear on the Operating display).

Output 2 controls the Slide Valve Load Solenoid. If 120VAC is found across Wires 17 and 2, the

Slide Valve Load Solenoid should be energized. If not, the solenoid is defective. If 120VAC is not

found when the LED for Output 2 is on, check the fuse (FU2).

Output 3 controls the Slide Valve Unload Solenoid. If 120VAC is found across Wires 16 and 2, the

Slide Valve Unload Solenoid should be energized. If not, the solenoid is defective. If 120VAC is

not found across Wires 16 and 2 when the LED for Output 3 is on, check the fuse (FU3).

NOTE: Verify that the proper setpoint has been programmed into C.C. (Capacity Control) on

the Adjustable Setpoints display.

SLIDE STOP DOES NOT Output 4 controls the Slide Stop 3.5 Vi Solenoid. If 120VAC is found across Wires 15 and 2, the

INCREASE and/or DECREASE Slide Stop 3.5 Vi Solenoid should be energized. If not, the solenoid is defective. If 120VAC is not

found across Wires 15 and 2 when the LED for Output 4 is on, check the fuse (FU4).

Outputs 4 and 5 control the Slide Stop 2.2 Vi Solenoid. If 120VAC is found across Wires 14 and 2,

the Slide Stop 2.2 Vi Solenoid should be energized. If not, the solenoid is defective. If 120VAC is

not found across Wires 14 and 2 when the LED for Output 5 is on, check the fuse (FU5).

LIQUID INJECTION SOLENOID Verify that the Liquid Injection TXV is modulating properly and not feeding excessive liquid to

DOES NOT ENERGIZE (LICO the compressor. When oil temperature drops too low, the microprocessor SHOULD de-energize

ONLY) this solenoid.

Output 6 controls the Liquid Injection Solenoid. If 120VAC is found across Wires 13 and 2, the

Liquid Injection Solenoid should be energized. If not, the solenoid is defective. If 120VAC is not

found when the LED for Output 6 is on, check the fuse (FU6).

HI Vi LIQUID INJECTION PORT Output 7 controls the Hi Vi Liquid Injection Port solenoid. If 120VAC is found across Wires 12 and

2, the Hi Vi Liquid Injection Port Solenoid should be energized. If not, the solenoid is defective.

If 120VAC is not found when the LED for output 7 is on, check the fuse (FU7).

NOTE: This output should only be on when the Vi is at 5.0.

ECONOMIZER (OPTIONAL) Output 8 controls the Economizer Solenoid Valve. If 120VAC is found across Wires 11 and 2,

SOLENOID DOES NOT the Economizer Solenoid should be energized. If not, the solenoid is defective. If 120VAC is not

ENERGIZE found when the LED for Output 8 is on, check the fuse (FU8).

NOTE: The economizer output should only lbe on when the slide valve is at or above the

90% position.

ALARM CIRCUIT DOES NOT Output 9 controls the Alarm Circuit. The Alarm should turn on only when there is a prealarm or

ENERGIZE shutdown. If the Alarm does not sound when these conditions are found, check for 120VAC

across Wires 10 and 2. If 120VAC is not found, check the fuse (FU9).

CONTROL PANEL DOES NOT Inputs 2 through 4 can be used to operate the compressor from a remote location.

RESPOND TO REMOTE

CONTROL SIGNALS NOTE: Check the Operating display to verify that the compressor and the Slide Valve

are in the REMOTE MODE.

If 120VAC is found (across Wires 21 and 2, 22 and 2, and 23 and 2) and the input does not turn

on, consult Frick Company.

MOTOR LOAD CONTROL The current transducer is used to convert the AC motor amps to a DC voltage signal for the

(FORCED UNLOAD) OCCURS microprocessor. If the %FLA reading from the Operating display is incorrect, consult Frick Co.

AT HIGH MOTOR AMPS

PRESSURES ON THE TEST 1 - Shut down the compressor and allow pressures to equalize. Discharge pressure

OPERATING DISPLAY and oil pressure should have the same reading.

DO NOT APPEAR CORRECT

TEST 2 - If either oil pressure or discharge pressure read different pressures, one or both

transducers are at fault. Valve off the suction transducer from the unit and open the vent

valve on transducer manifold to atmosphere. If the suction transducer reads atmospheric

pressure, then the suction transducer is correct.

NOTE: A 1% tolerance is allowed for all transducers.

COMPRESSOR DOES NOT Verify that the [AUTO] key has been pressed and AUTO appears under SV Pos on the

AUTOMATICALLY Operating display #4.

LOAD OR UNLOAD

If the problem persists, see the Troubleshooting section SLIDE VALVE DOES NOT LOAD

and/or UNLOAD.

MAINTENANCE

Loading...

Loading...