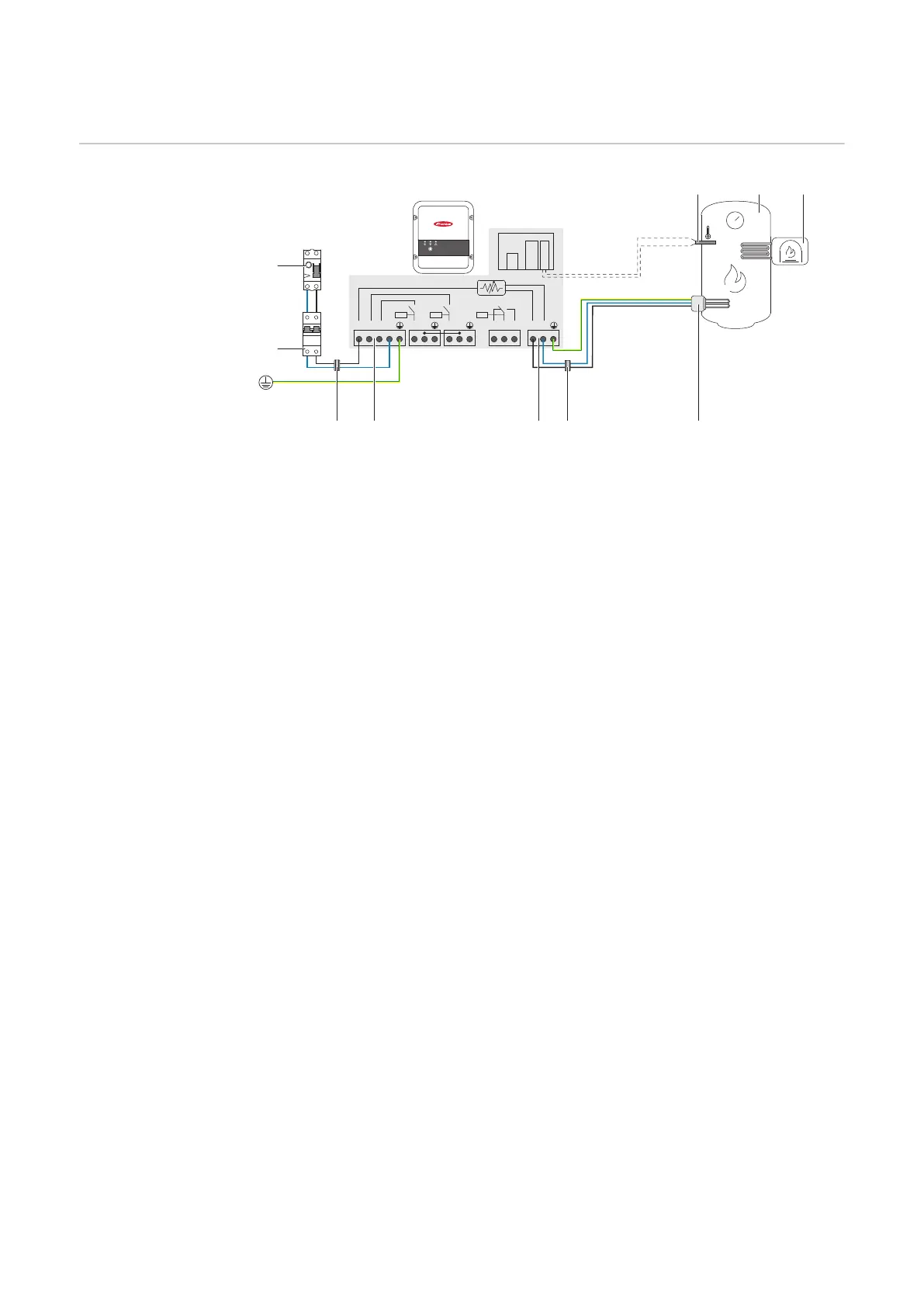

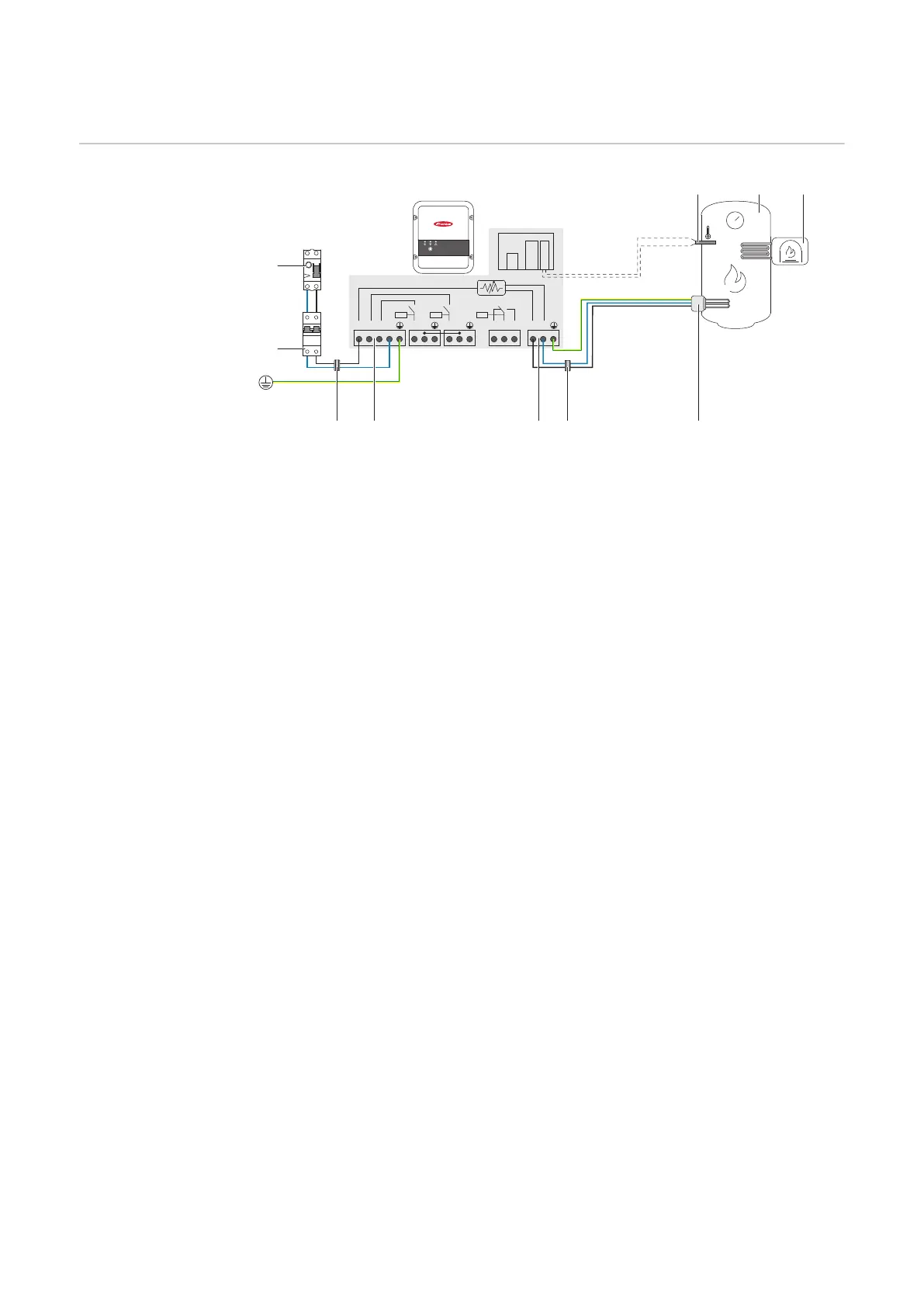

1-phase heating element up to 3 kW

Application ex-

ample 1

L1 L2 L3 N L3 N L2 N NC W OUT NNO

R2 R3

LAN

RS485

PT1000

max. 16A

(2)

(7)

(6)

(1) (3)

(9)

(8)

External earth

(PE)

(4)(5)(5)

(1) Temperature sensor PT1000

(2) Hot water boiler

(3) External source (e.g. gas-fired heating)

(4) Heating element (max. 3 kW)

(5) Ferrite rings (included in scope of delivery)

(6) Output up to 3 kW variable, max. 13 A resistive load, spring-loaded ter-

minal 1.5 - 2.5 mm²

(7) Input - grid supply 1x 230V network, spring-loaded terminal 1.5 - 2.5 mm²

(8) Residual-current circuit breaker

(9) Automatic circuit breaker max. B16A

IMPORTANT! Plug & Play - no further settings are required for this application

after successful connection to the inverter.

The Fronius Smart Meter records the current power at the feed-in point and

transfers the data to the inverter. By controlling the Ohmpilot, the inverter ad-

justs any surplus energy that is available to zero. Specifically, this takes place by

continuously adjusting the heating element connected to the Ohmpilot. Surplus

energy is consumed using the heating element in a continuously variable manner.

If no temperature sensor is fitted, an external source (e.g. gas-fired heating)

must be used to ensure the minimum temperature is met.

As an alternative, the Ohmpilot can ensure the minimum temperature. To do this,

a temperature sensor must be connected so that the Ohmpilot can measure the

temperature. This may result in electricity being sourced from the grid.

The maximum temperature must be set on the heating element thermostat. If

the heating element does not have a thermostat, the Ohmpilot can also carry out

this task as an alternative (see "Optional settings" section Optional settings on

page 45).

24

Loading...

Loading...