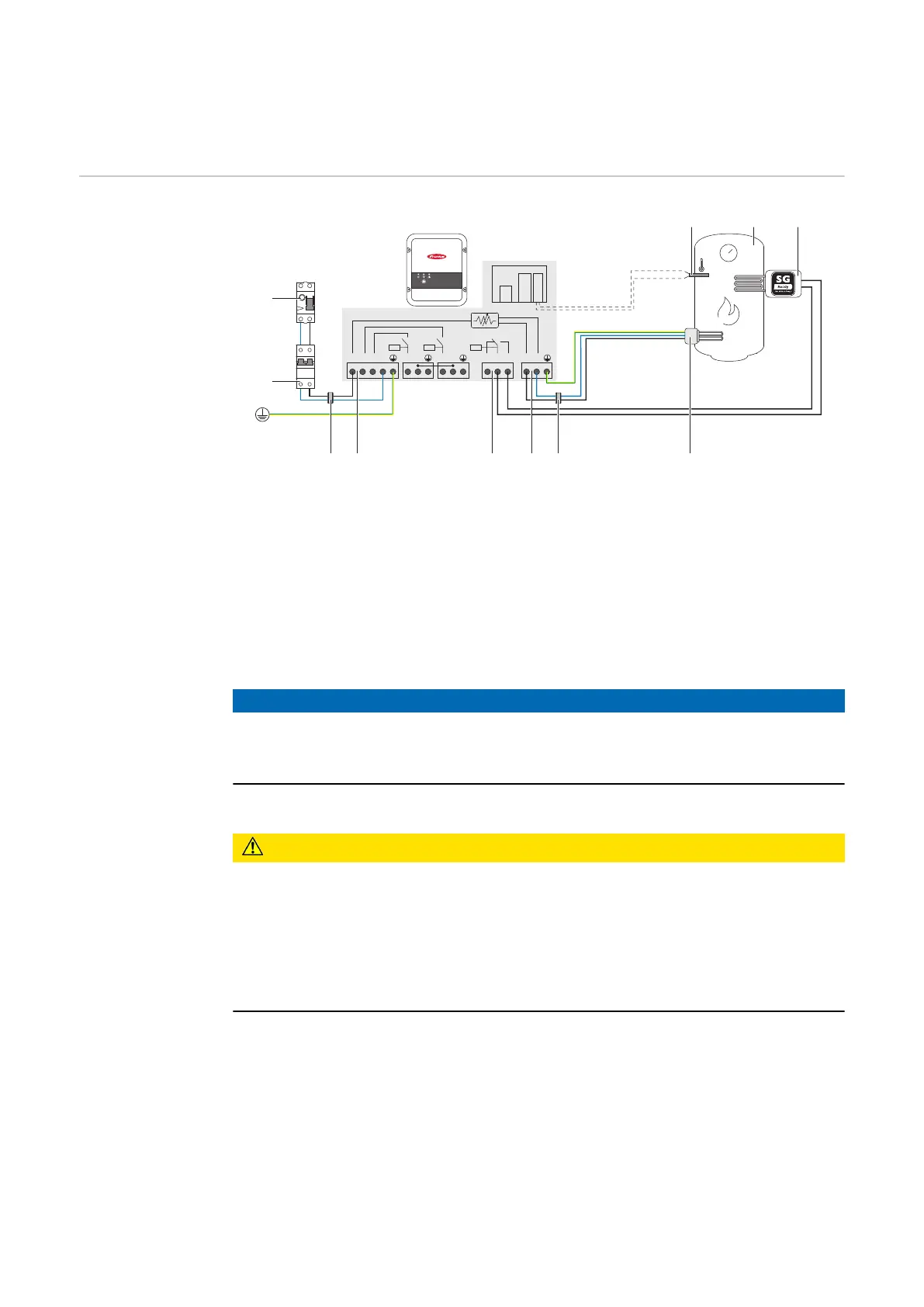

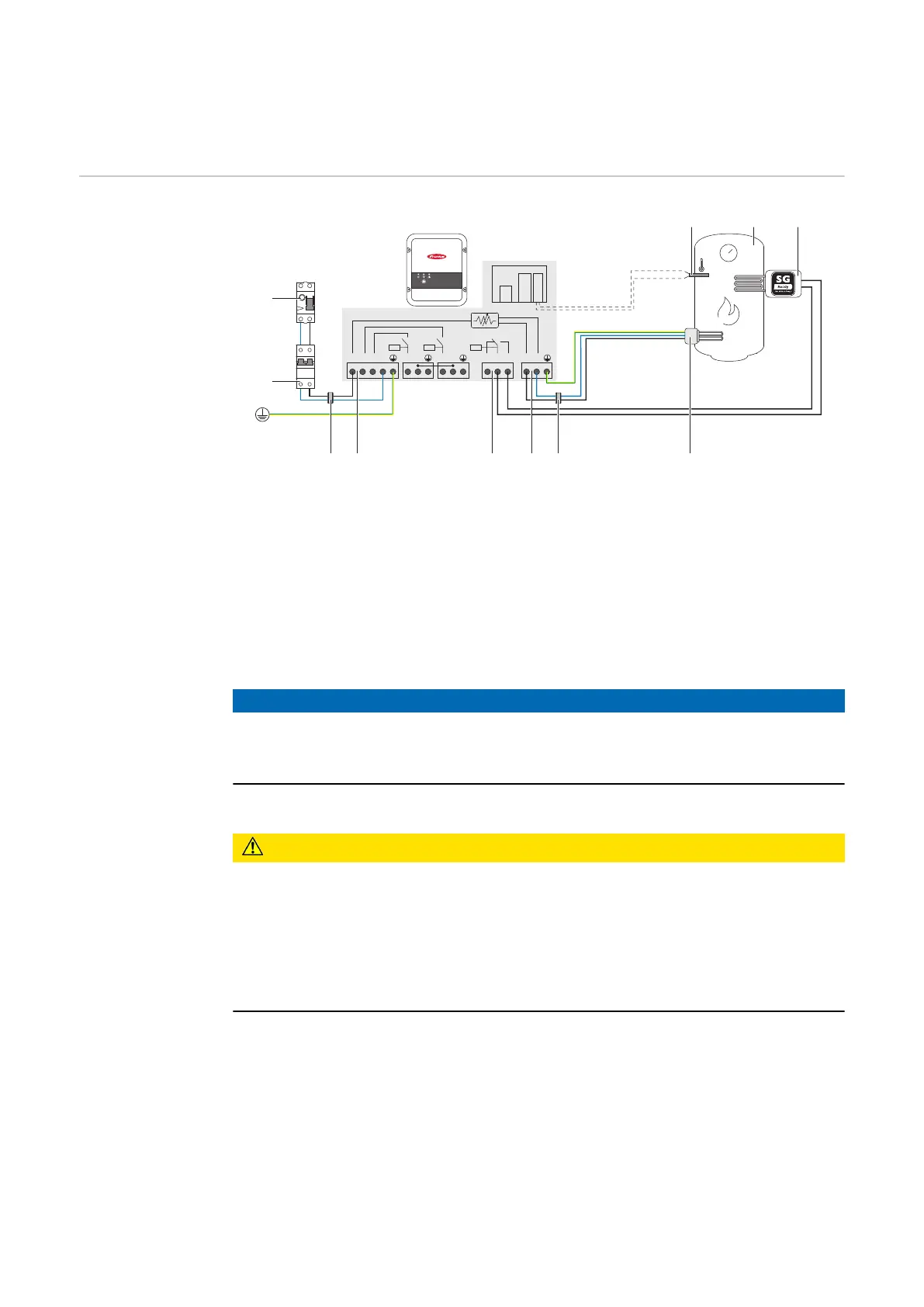

1-phase heating element up to 3 kW with heat

pump control

Application ex-

ample 3

L1 L2 L3 N L3 N L2 N NC W OUT NNO

R2 R3

LAN

RS485

PT1000

max. 16A

(2)

(8)

(6)

(1) (3)

(10)

(9)

External earth

(PE)

(4)(5)(5) (7)

(1) Temperature sensor PT1000

(2) Hot water boiler

(3) Heat pump with SG Ready control input

(4) Heating element (max. 3 kW)

(5) Ferrite rings (included in scope of delivery)

(6) Output up to 3 kW variable, max. 13 A resistive load, spring-loaded ter-

minal 1.5 - 2.5 mm²

(7) Multifunctional relay output

NOTE!

Relay contacts can oxidise.

The voltage must be at least 15 V and the current at least 2 mA, so that the relay

contacts do not oxidise.

(8) Input - grid supply 1x 230V network, spring-loaded terminal 1.5 - 2.5 mm²

CAUTION!

Danger due to contact with live, stripped wires

A short circuit can be triggered and damage the device.

▶

Carry out all connection work in accordance with the applicable electrotech-

nical guidelines and regulations.

▶

Observe the maximum stripping length of 10 mm.

▶

When connecting the phases, tie the individual wires together with a cable tie

immediately before the terminal.

(9) Residual-current circuit breaker

(10) Automatic circuit breaker max. B16A

The Fronius Smart Meter records the current power at the feed-in point and

transfers the data to the inverter. By controlling the Ohmpilot, the inverter ad-

justs any surplus energy that is available to zero. Specifically, this takes place by

continuously adjusting the heating element connected to the Ohmpilot and by

targeted switching on of the heat pump.

For activation, the heat pump must have a control input (SG Ready or approval

from grid operator). The heat pump can be switched from normal operation to

26

Loading...

Loading...