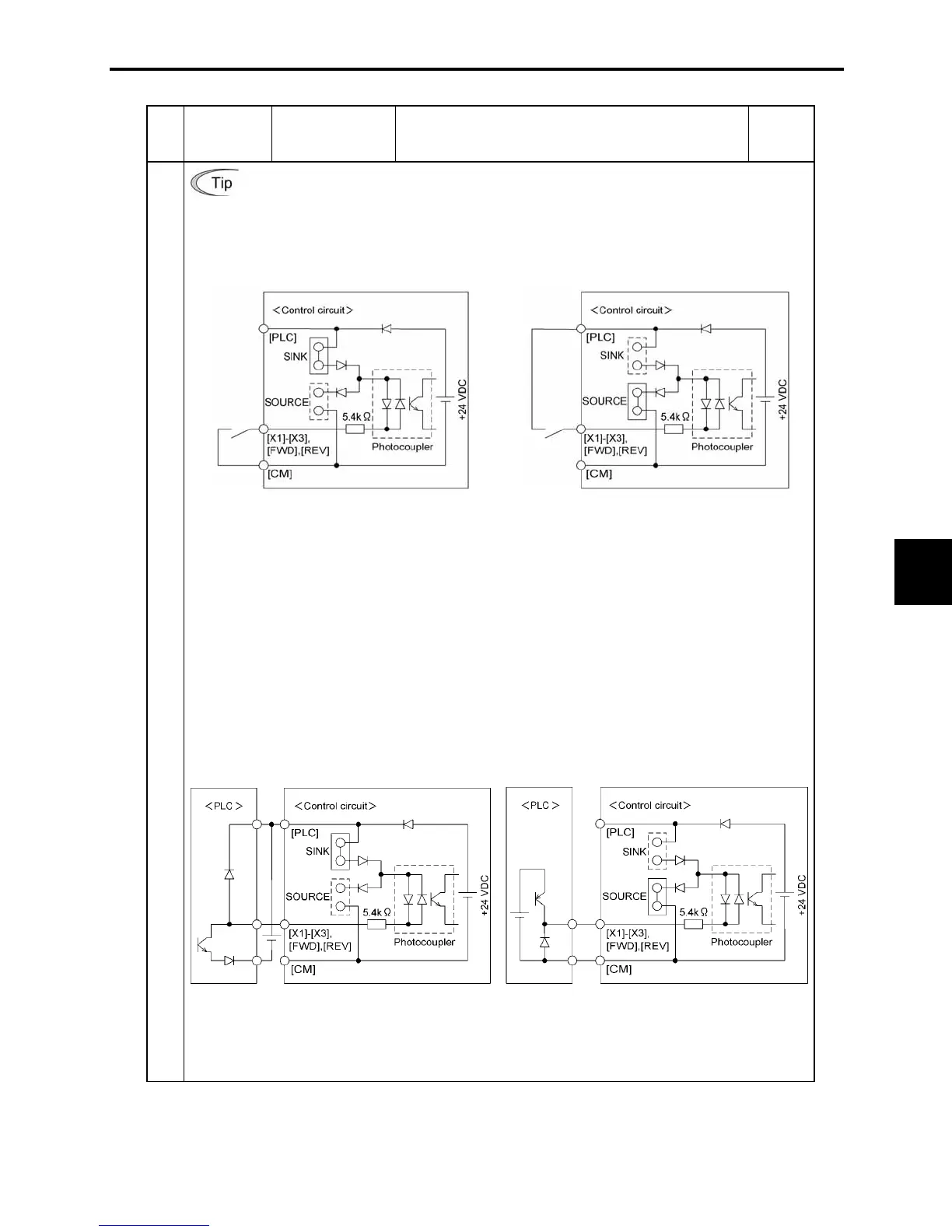

Turning ON or OFF [X1], [X2], [X3], [FWD], or [REV] using a relay contact

Figure 8.3 shows two examples of a circuit that turns ON or OFF control signal input

[X1], [X2], [X3], [FWD], or [REV] using a relay contact. Circuit (a) has a connecting

jumper applied to SINK, whereas circuit (b) has it applied to SOURCE.

NOTE: To configure this kind of circuit, use a highly reliable relay

(Recommended product: Fuji control relay Model HH54PW.)

(a) With a jumper applied to SINK (b) With a jumper applied to SOURCE

Figure 8.3 Circuit Configuration Using a Relay Contact

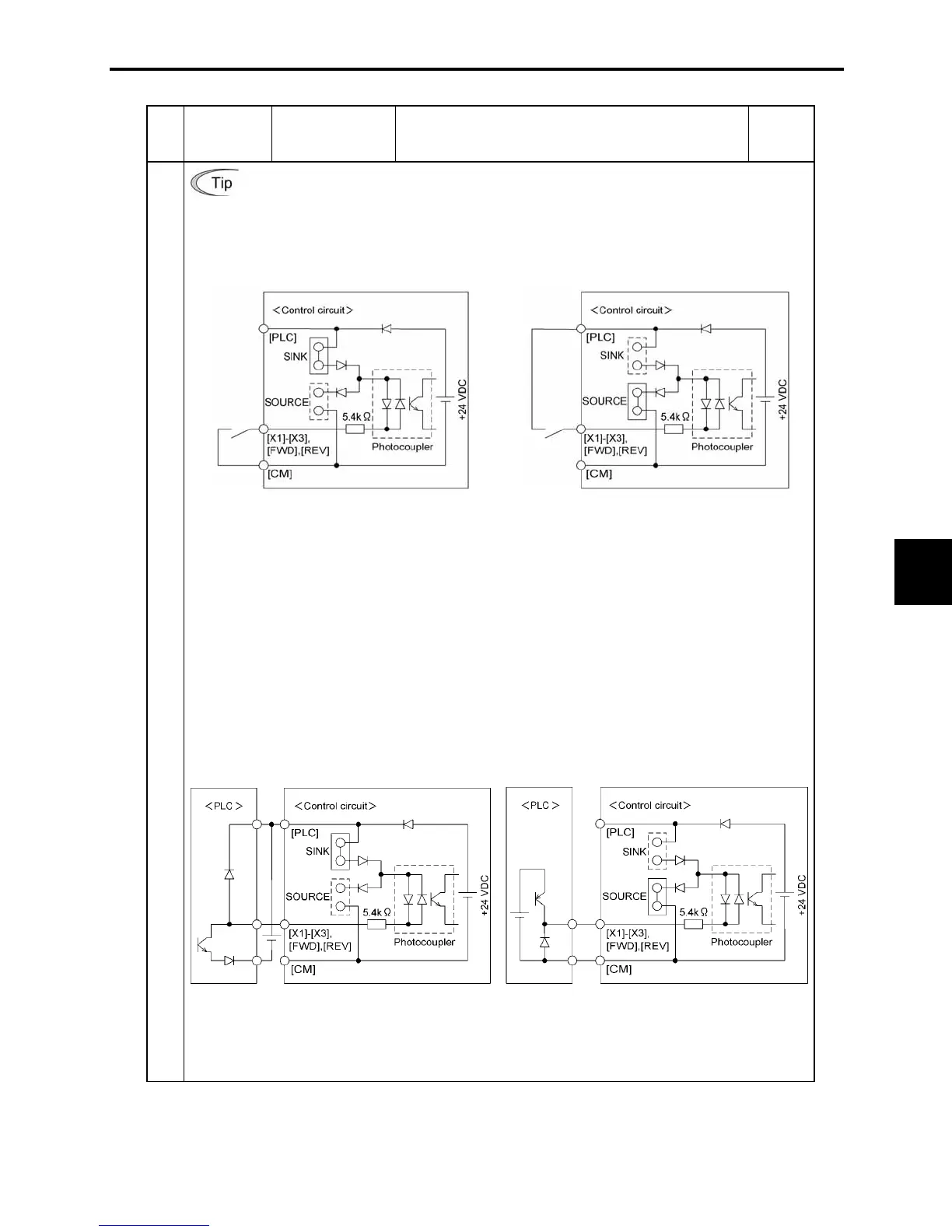

Turning ON or OFF [X1], [X2], [X3], [FWD], or [REV] using a programmable

logic controller (PLC)

Figure 8.4 shows two examples of a circuit that turns ON or OFF control signal input

[X1], [X2], [X3], [FWD], or [REV] using a programmable logic controller (PLC). Circuit

(a) has a connecting jumper applied to SINK, whereas circuit (b) has it applied to

SOURCE.

In circuit (a) below, short-circuiting or opening the transistor's open collector circuit in

the PLC using an external power source turns ON or OFF control signal [X1], [X2], [X3],

[FWD], or [REV]. When using this type of circuit, observe the following:

• Connect the + node of the external power source (which should be isolated from the

PLC's power) to terminal [PLC] of the inverter.

• Do not connect terminal [CM] of the inverter to the common terminal of the PLC.

Digital input

(a) With a jumper applied to SINK (b) With a jumper applied to SOURCE

Figure 8.4 Circuit Configuration Using a PLC

For details about the jumper setting, refer to the FRENIC-Mini Instruction Manual, Chapter 2, Section

2.3.8 "Switching of SINK/SOURCE (jumper switch)."

Loading...

Loading...