8-26

8.5 Operating Environment and Storage Environment

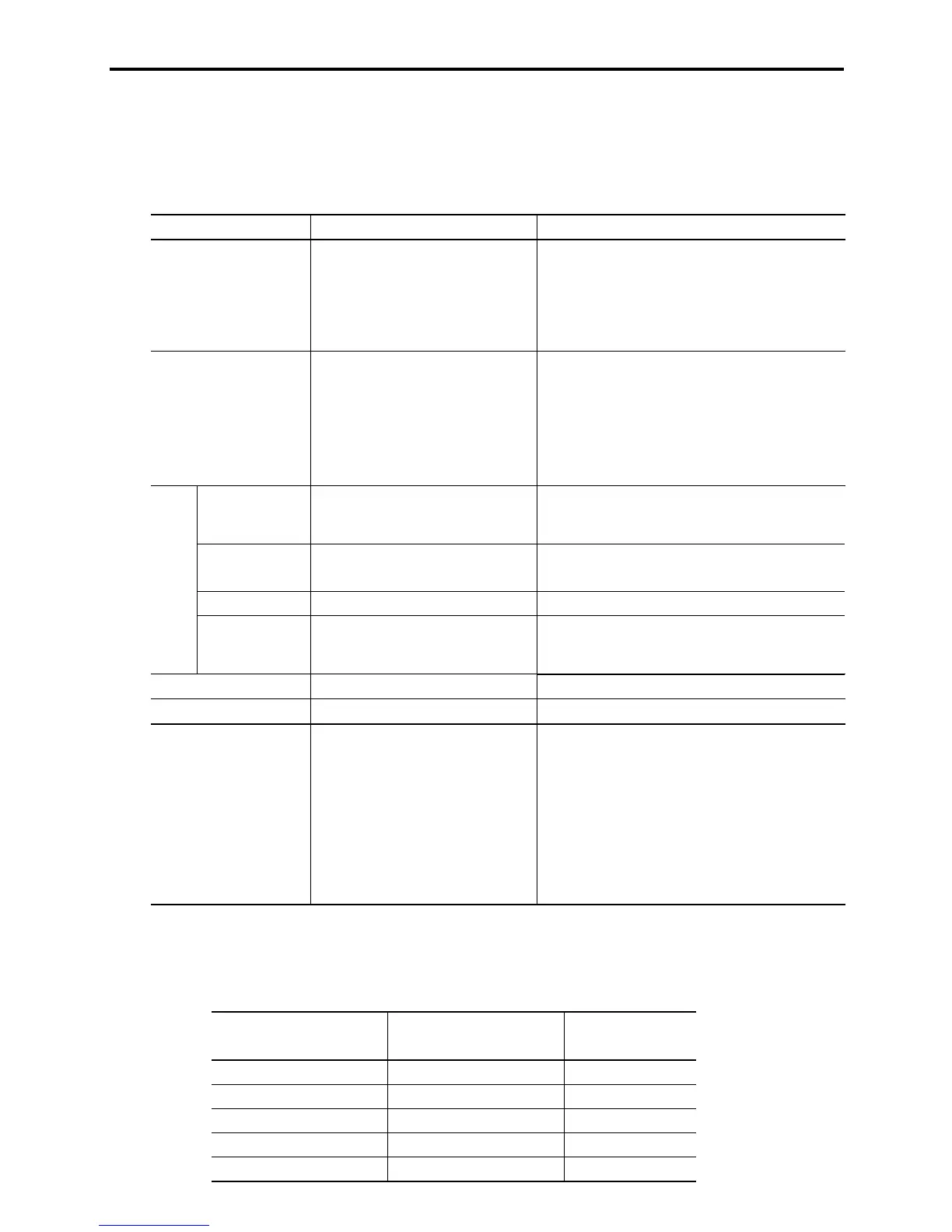

8.5.1 Operating environment

The operating environment for FRENIC-Mini shows below.

Item Specifications Careful site for installation

Ambient temperature

*1

-10 to +50qC (+14 to 122qF)

Places around heating machines like furnace,

constant temperature bath, or boiler

Enclosed cases or rooms

Tropical region or outdoor machinery

Cold room or cold region

Relative humidity 5 to 95% (No condensation)

Inside of dryer machines for brewing, food or

wood processing

Transportation equipment for frozen food

Inside of tunnel

Places where there is much ice and snow

Places where water or steam is used

Dust Clean

Foundry, cement plant, spinning mill, fertilizer

mill, flouring mill, iron factory, timber mill,

construction site, the places around grinder

Salinity Little

(0.01 mg/cm

2

or less per year)

Places like coast or shipping that is susceptible

to sea salt

Oil mist None Places where oil like grinding fluid gets mist

Atmosphere

*2

㩷

Flammable gas

Corrosive gas

None

Chemical factory, oil refinery, fuel gas facility,

gas station, water treatment plant, hot spring

region, geothermal power station, colliery

Altitude

*3

3300 ft (1000 m) or lower Mountainous region, heights

Atmospheric pressure 86 - 106 kPa

Vibration

0.12 inch (3 mm)

2 to 9 Hz or lower

(Max. amplitude)

32.2 ft/s

2

(9.8 m/s

2

)

9 - 20 Hz or lower

6.6 ft/s

2

(2.0 m/s

2

)

20 - 55 Hz or lower

3.3 ft/s

2

(1.0 m/s

2

)

55 - 200 Hz or lower

Vehicle, shipping, machinery

*1 The inverter must not be subjected to sudden changes in temperature that will cause condensation to form.

*2 Do not install the inverter in an environment where it may be exposed to cotton waste or moist dust or dirt which will clog the heat sink

in the inverter. If the inverter is to be used in such an environment, install it in the control board of your system or other dustproof

containers.

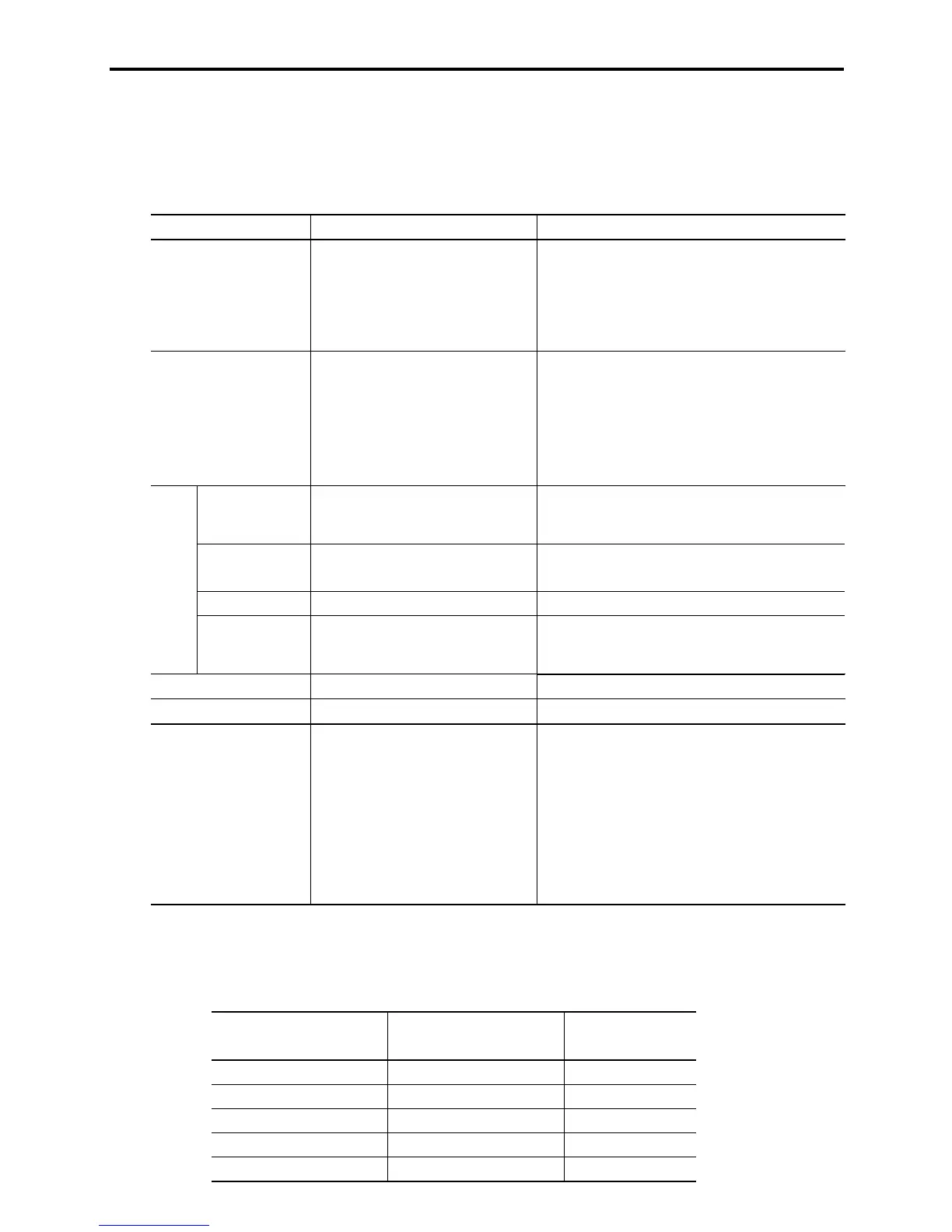

*3 If you use the inverter in altitude above 3300 ft (1000 m), you should apply a reduction factor of withstand voltage test and an output

current reduction factor as listed below when selecting the inverter properly.

Altitude [ft (m)]

Reduction factor of

withstand voltage test

Output current

reduction factor

3300 (1000) or lower 1.00 1.00

3300 to 4900 (1000 – 1500) 0.95 0.97

4900 to 6600 (1500 – 2000) 0.90 0.95

6600 to 8200 (2000 – 2500) 0.85 0.91

8200 to 9800 (2500 – 3000) 0.80 0.88

Loading...

Loading...