v

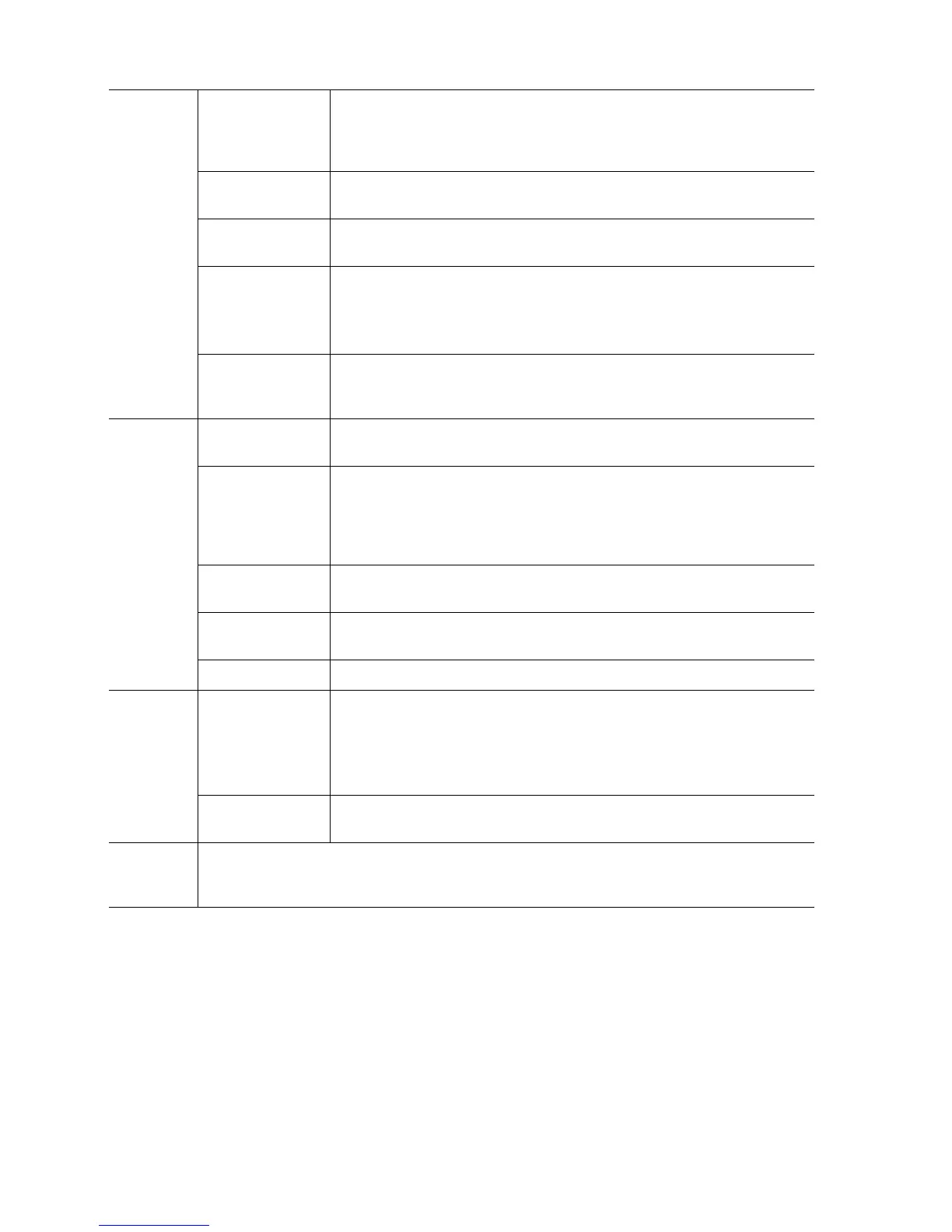

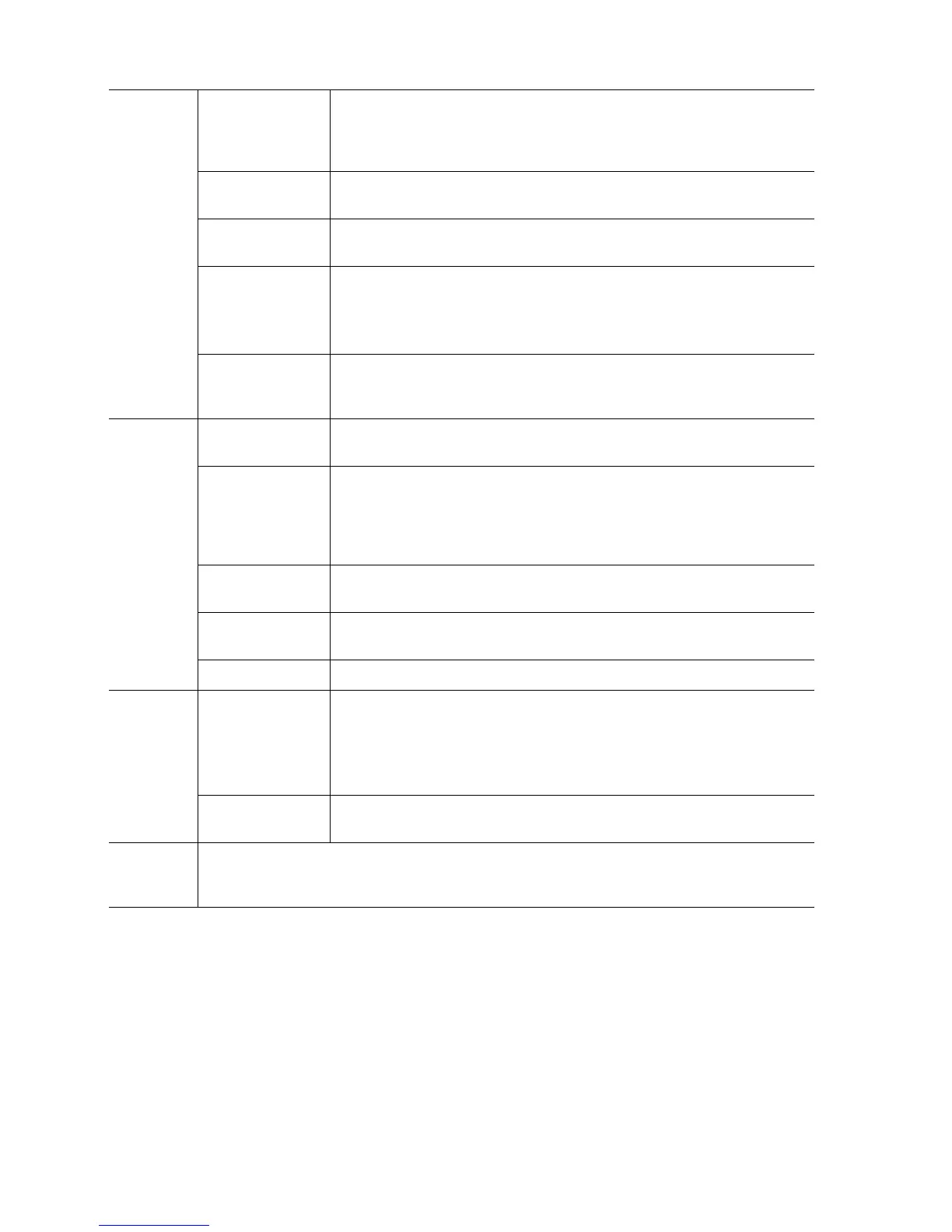

Discontinuance of

power-factor

correcting

capacitor

Do not mount power-factor correcting capacitors in the inverter’s primary

circuit. (Use the DC reactor to improve the inverter power factor.) Do not

use power-factor correcting capacitors in the inverter output circuit. An

overcurrent trip will occur, disabling motor operation.

Discontinuance of

surge killer

Do not connect a surge killer to the inverter's secondary circuit.

Reducing noise

Use of a filter and shielded wires is typically recommended to satisfy EMC

directives.

Measures against

surge currents

If an overvoltage trip occurs while the inverter is stopped or operated under

a light load, it is assumed that the surge current is generated by open/close

of the phase-advancing capacitor in the power system.

* Connect a DC reactor to the inverter.

Combina-

tion with

peripheral

devices

Megger test

When checking the insulation resistance of the inverter, use a 500 V megger

and follow the instructions contained in the FRENIC-Mini Instruction

Manual, Chapter 7, Section 7.4 "Insulation Test."

Control circuit

wiring length

When using remote control, limit the wiring length between the inverter and

operator box to 65.6 ft (20 m) or less and use twisted pair or shielded cable.

Wiring length

between inverter

and motor

If long wiring is used between the inverter and the motor, the inverter will

overheat or trip as a result of overcurrent (high-frequency current flowing

into the stray capacitance) in the wires connected to the phases. Ensure that

the wiring is shorter than 164 ft (50 m). If this length must be exceeded,

lower the carrier frequency or mount an output circuit filter (OFL).

Wiring size

Select wires with a sufficient capacity by referring to the current value or

recommended wire size.

Wiring type

Do not use one multicore cable in order to connect several inverters with

motors.

Wiring

Grounding Securely ground the inverter using the grounding terminal.

Driving

general-purpose

motor

Select an inverter according to the applicable motor ratings listed in the

standard specifications table for the inverter.

When high starting torque is required or quick acceleration or deceleration

is required, select an inverter with a capacity one size greater than the

standard.

Selecting

inverter

capacity

Driving special

motors

Select an inverter that meets the following condition:

Inverter rated current > Motor rated current

Transpor-

tation and

storage

When transporting or storing inverters, follow the procedures and select locations that meet the

environmental conditions listed in Chapter 1, Section 1.3 "Transportation" and Section 1.4

"Storage Environment."

Loading...

Loading...