VMP-IOMM-2018-2

Fulton Ltd

Page 65

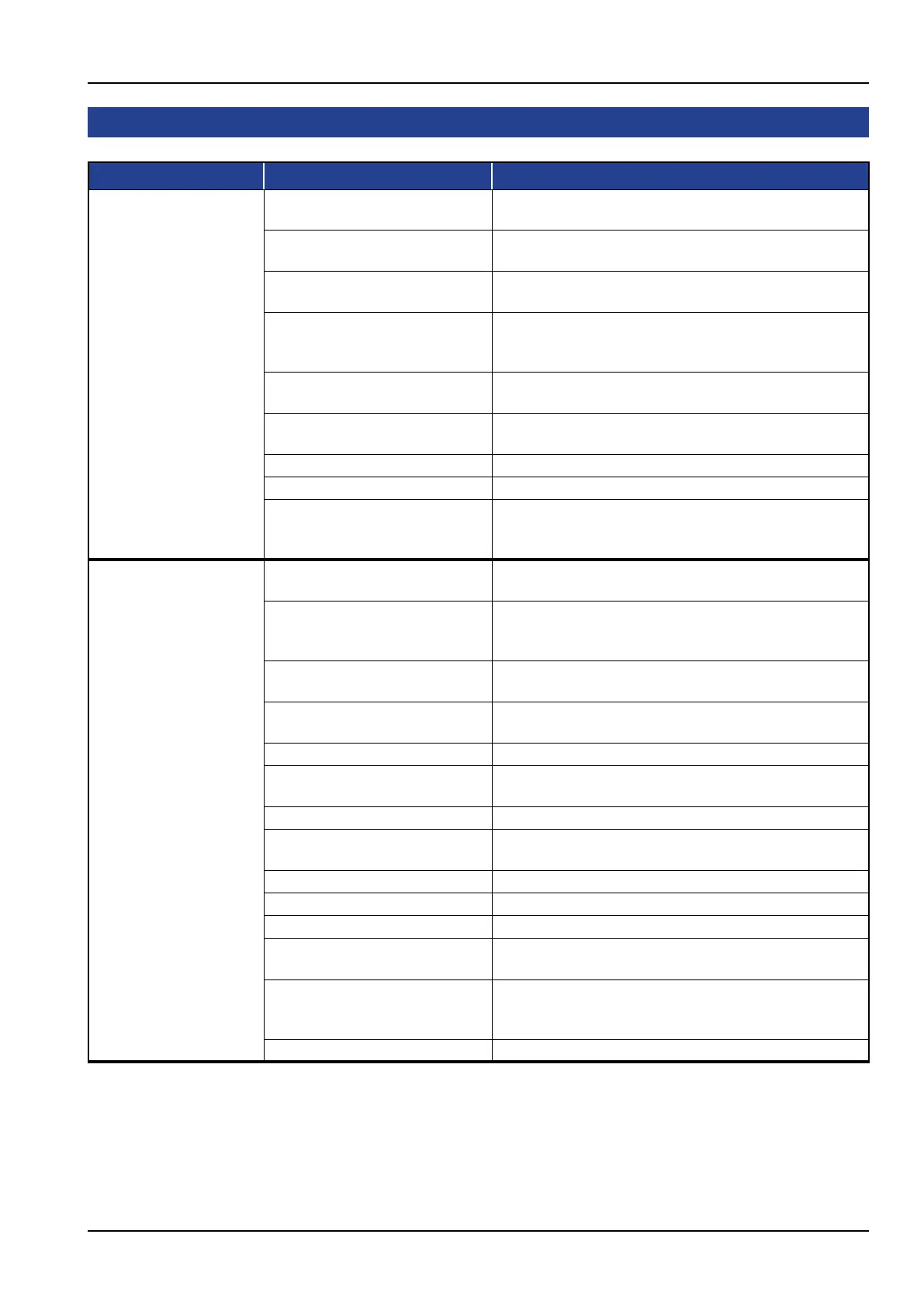

TROUBLESHOOTING - 6

6.2 TROUBLESHOOTING OIL BOILER

CONTINUED ON NEXT PAGE

Problem Cause Remedy

5. Poor combustion 1. Refractory bricks Check the bricks are not plugged with soot or broken into

pieces. Clean and replace as required.

2. Stainless steel ring Checktoensuretheringispresentandtssecurely

against the furnace wall.

3. Main air adjustment Checkairadjustment.Openmainairuntilrebrushesthe

furnace wall.

4. Secondary air adjustment. Check main air adjustment to see if it has moved. Adjust

as necessary and tighten in position. Check CO

2

and O

2

level.

5. Draft Check draft is neutral. Consider installing a barometric

damper if the draft is too strong.

6. Dirtyue CheckueforCarbonbuild-uporblockage.Cleanue

passages with brush.

7. Negative room pressure Ensure no exhaust fans are running in the boiler room.

8. Oil nozzle Check for blocked nozzle, clean or replace as necessary.

9. Oil pump Checkforblockedstrainerorlter.Removeorclean.

Check for slipping or broken coupling. Tighten or replace.

Check for seized pump shaft. Replace.

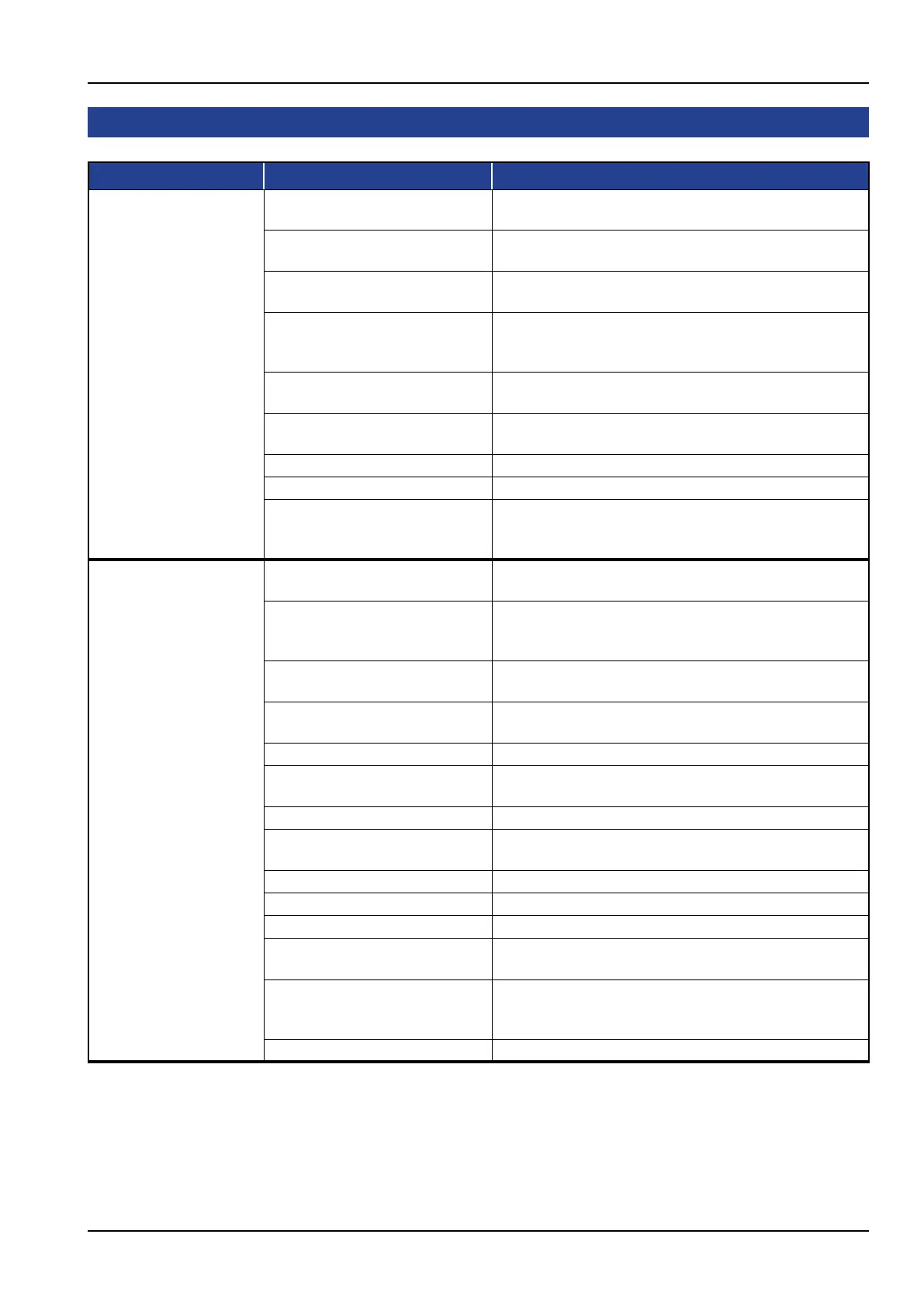

6. 1. Refractory bricks Check the bricks are not plugged with soot or broken into

pieces. Clean and replace as required.

2. Ignition electrodes Check electrodes for carbon build-up, clean if required.

Check settings adjust if required. Check for cracks in

porcelain, if found, replace.

3. UV detector Check for dirt on scanner, clean as required. Check for

proper location of detector.

4. Draft problem Check draft is neutral. Consider installing a barometric

damper if the draft is too strong.

5. Negative room pressure Ensure no exhaust fans are running in the boiler room.

6. Primary air adjustment Checkairadjustment.Airmaybeblowingre

awayfromamedetector.

7. Oil valve(s) Check for leaking oil valve(s) and replace.

8. Loss of oil prime Check all lines for possible air leak in intake line and

tighten. Check for possible restricted intake line. Replace.

9. Looseoilttings Checkallttingsandtighten.

10. Blockedoillter Check and clean or replace.

11. Blocked screen in oil pump Check and clean or replace.

12. Blockedue Checkueisnotblocked,cleanasrequired.

Checkdraftatue.

13. Vacuum on pump Check for too high a vacuum on the pump.

Check oil lines and distance from tank to boiler.

Repair or replace as necessary.

14. Hole in suction line Check and replace as necessary.

Loading...

Loading...