VMP-IOMM-2018-2

Fulton Ltd

Page 66

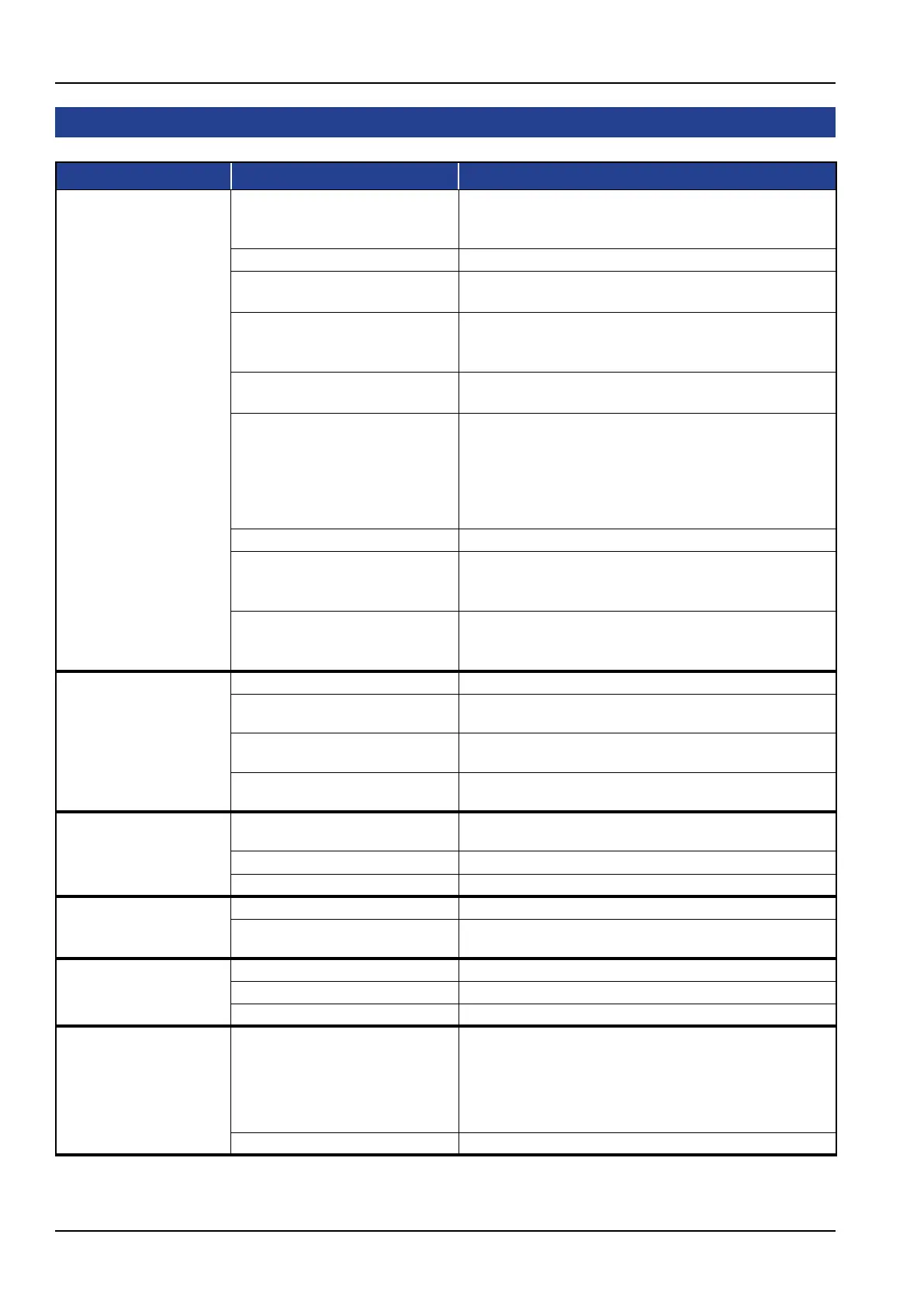

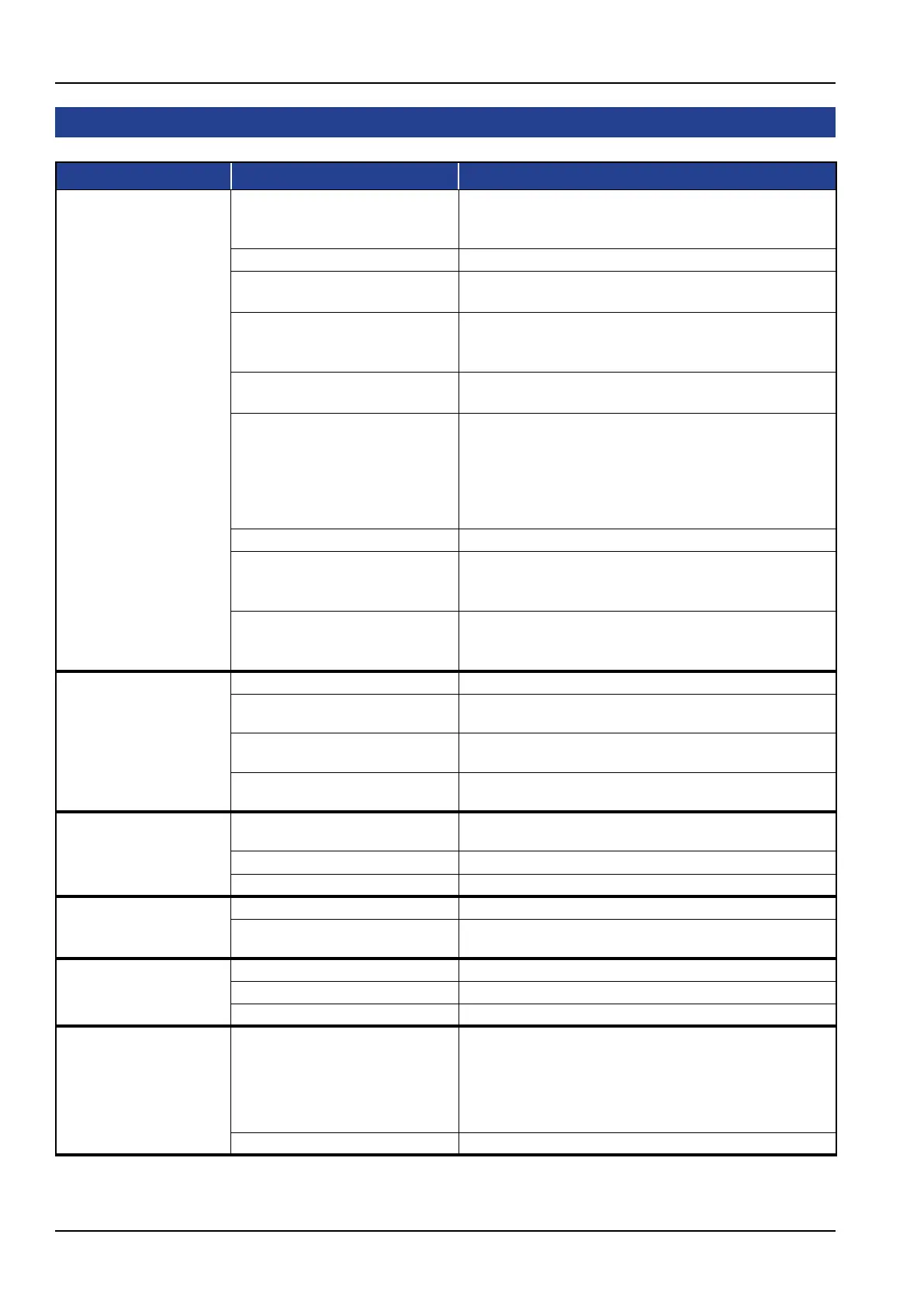

TROUBLESHOOTING - 6

6.2 TROUBLESHOOTING OIL BOILER

CONTINUED ON NEXT PAGE

Problem Cause Remedy

7. Boiler will not

maintain pressure

1. Oil tank empty Relltheoiltank.Aslightdelayinthere-primingofthe

fuel pump may cause the burner programmer to require

resetting before the boiler operates satisfactorily.

2. Oil nozzle Check for blocked nozzle. Clean or replace.

3. Oil valve Check voltage between oil valve leads at terminal block to

be sure oil valve is getting power.

4. Oil pump Checkforblockedstrainerorlter.Removeandclean.

Check for slipping or broken coupling, tighten or replace.

Check for seized pump shaft. Replace the pump.

5. Dirtyue CheckueforCarbonbuild-uporblockage.Cleanue

passages with brush.

6. Pressure control Disconnect all power to the controller. Disconnect the

wires from the controller. Place an OHM meter between

the switch terminals. Lower the set point of the controller,

the switch should make. Raise the set point and recheck,

switch should break. If the controller operates improperly,

replace it.

7. Scale build-up in boiler Consult Fulton.

8. Refractory bricks Check the bricks are not plugged with soot, cracked

or broken into pieces. Clean and replace as

required.

9. Boiler size Boiler may be under sized for the application. Consult

Fulton.

8. Boiler is surging 1. Steam traps blowing through. Check traps, clean or replace as required.

2. Scale build-up or lime deposits. Call water treatment company and

consult the factory.

3. Too much water treatment Dumpthereturntankandushthesystem.

Test the water treatment.

4. Too much of a load. Check total equipment load against the boiler output.

Decrease amount of equipment being used.

9. Boiler rumbles 1. Draft problem Check draft is neutral. Consider installing a barometric

damper if the draft is too strong.

2. Too much main air. Adjust main air.

3. Air or water in the oil. Check tank and lines for water or leaks.

10. Boiler pushing

steam

1. Steam traps Check traps. Clean or replace as required.

2. Too much water treatment. Dumpthereturntankandushthesystem.Test the water

treatment.

11. Pump will not cut off 1. Dirty probes. Clean or replace as required

2. Relay failed. Check relay is secure on its base, if so, replace the relay.

3. Earth connection. Check for tightness and clean.

12. Pump runs but does

not put water in the

boiler

1. Vapour locking of pump. Allow system to cool down, check steam traps of pump

and check to be sure return lines are not insulated. Check

return tank temperature, if it is above 82 °C vapour locking

of the pump will occur. Inspect check valves. Clean

and replace as needed. Replace pump with multi-stage

centrifugal pump able to cope with 121 °C.

2. Blocked feed water line Check feedwater line is not blocked, clean as required.

Loading...

Loading...