Do you have a question about the GE Optica and is the answer not in the manual?

Overview of the GE Infrastructure Sensing Optica as a multi-purpose chilled-mirror hygrometer.

Details on the available configurations for the Optica unit: benchtop and wall-mount.

Description of the Optica's front panel layout and display options (VGA and 4x40).

Available inputs and outputs for the Optica, including sensor inputs and communication ports.

Components of a complete Optica system and planning considerations for applications.

Information on compatible chilled-mirror dew point, temperature, and pressure sensors.

Explanation of optical condensation hygrometry and how the Optica measures dew point.

How GE Infrastructure Sensing hygrometers detect and measure dew point using a condensate mirror.

Procedures and recommendations for calibrating the Optica unit using NIST or other labs.

Usage of hygrometers in industrial applications and their limitations.

Explanation of the PACER (Programmable Automatic Contaminant Error Reduction) technique for accuracy.

Explains the installation of benchtop and wall-mount versions, sensors, and wiring.

Details on mounting the Optica benchtop unit, including dimensions and options.

Instructions for mounting the benchtop unit in a standard 19-inch rack using an optional kit.

Guidance on mounting the Optica Wall-Mount unit on a flat, vertical surface.

Wiring details for analog outputs and terminal blocks for both benchtop and wall-mount units.

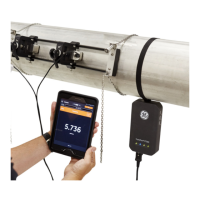

Information on various GE Infrastructure Sensing dew point sensors compatible with the Optica.

Installation details for specific GE Infrastructure Sensing dew point sensors like Model 1111H and D-2.

Outlines the three categories of operating instructions: normal operation, setup/programming, and maintenance.

Simple steps for turning on the unit and basic operation after power-up.

How parameters are displayed numerically and graphically on the VGA display.

How parameters are displayed numerically on the 4x40 display and its status indicators.

How the VGA Optica can be operated and programmed remotely over a network.

Methods for measuring or specifying sample gas pressure for humidity measurements.

Explains the meaning of various status indications displayed on the unit.

Procedures for balancing the sensor optics to maintain optimum performance.

Tips and considerations for optimizing unit operation and understanding response times.

How the Optica is programmed to display and output data for various applications.

Basic principles of programming using menu screens, data fields, and control buttons.

Lists available units of measure for humidity, temperature, and pressure parameters.

How to define custom equations to calculate new parameters for output.

Details on programming Analog Outputs, Pressure Input, Alarms, and Automatic Cleaning/Balance.

Covers General Settings, Special options, User Equations, Communication Parameters, and Serial Output Data.

How to program the 4x40 Optica for data display, output, and alarm settings.

General method for programming the 4x40 unit using softkeys and the keypad.

Lists and describes programmable functions like Analog Outputs and Communication Parameters.

How to program the VGA Optica remotely via a network using a web browser.

Details on using the Optica Web interface and its similarity to VGA programming.

Procedures for periodic inspection and maintenance of sensor optics, including mirror cleaning.

Steps to adjust optical balance for proper sensor operation and accuracy.

Instructions for user-replaceable mirrors and reasons for replacement.

Procedures for testing and calibrating aspects like power supply, sensor operation, and outputs.

Common issues like display problems and 'Service' indicator, with solutions.

Detailed specifications for accuracy, sensitivity, repeatability, and measurement ranges.

Specifications for outputs, displays, power, and operating ranges of the Optica.

Dimensions, weight, and environmental specifications for the benchtop unit.

Dimensions, weight, and environmental specifications for the wall-mount unit.

List of optional accessories available for the Optica system.

Symbols used in humidity equations and the context of vapor pressure calculations.

Equations defining saturation vapor pressure with respect to water and ice.

Definitions and equations for relative humidity, absolute humidity, and parts per million.

Wiring diagram and pin usage for connecting the Optica to a personal computer via serial interface.

Overview of GE Infrastructure Sensing's five interchangeable chilled mirror sensors.

Explanation of Peltier devices as heat pumps and their role in depression capability.

Defines measurement range and factors influencing it, like depression capability and gas properties.

Comparison chart detailing system performance and functional characteristics of different Optica sensor models.

Definition of the temperature difference by which a chilled mirror can be lowered from ambient.

Definition of Local Area Network (LAN) and Wide Area Network (WAN) in the context of Optica operation.

Definition of the GE Infrastructure Sensing patented Programmable Automatic Contaminant Error Reduction system.

Definition of a measured quantity available for display on the unit.

Definition of gas pressure of the system under test, potentially measured at lower pressure.

Process of selecting maximum and minimum output values for a parameter.

Explanation of the SHIFT key's function for accessing modes and non-numeric characters.

Description of the four keys to the right of the display and their context-dependent functions.

Generic description of a 640x480 pixel display, identifying the large-screen Optica.

Definition of four lines by 40 characters per line, identifying the small-screen Optica.

Instructions for programming automatic balance for earlier VGA Optica software versions.

Instructions for programming automatic balance for earlier 4x40 Optica software versions.

Network configuration for OPTICA VGA/4x40 models using RS-232 port and commands.

How the Optica communicates over port 28005 using IP address and commands.

How to find supported API commands by entering a URL in a browser.

Example command and response for retrieving alarm settings from the Optica.

Command to retrieve supported alarm types and their referencing order from the Optica.

Command to retrieve supported units and their referencing order from the Optica.

Command to retrieve units, labels, and their indices for humidity, temperature, and pressure.

Command to retrieve settings for the two analog outputs from the Optica.

Command to retrieve measured/calculated values and status information from the Optica.

Steps to set network settings for the 4x40 Optica using RS-232 communication.

| Brand | GE |

|---|---|

| Model | Optica |

| Category | Measuring Instruments |

| Language | English |