123

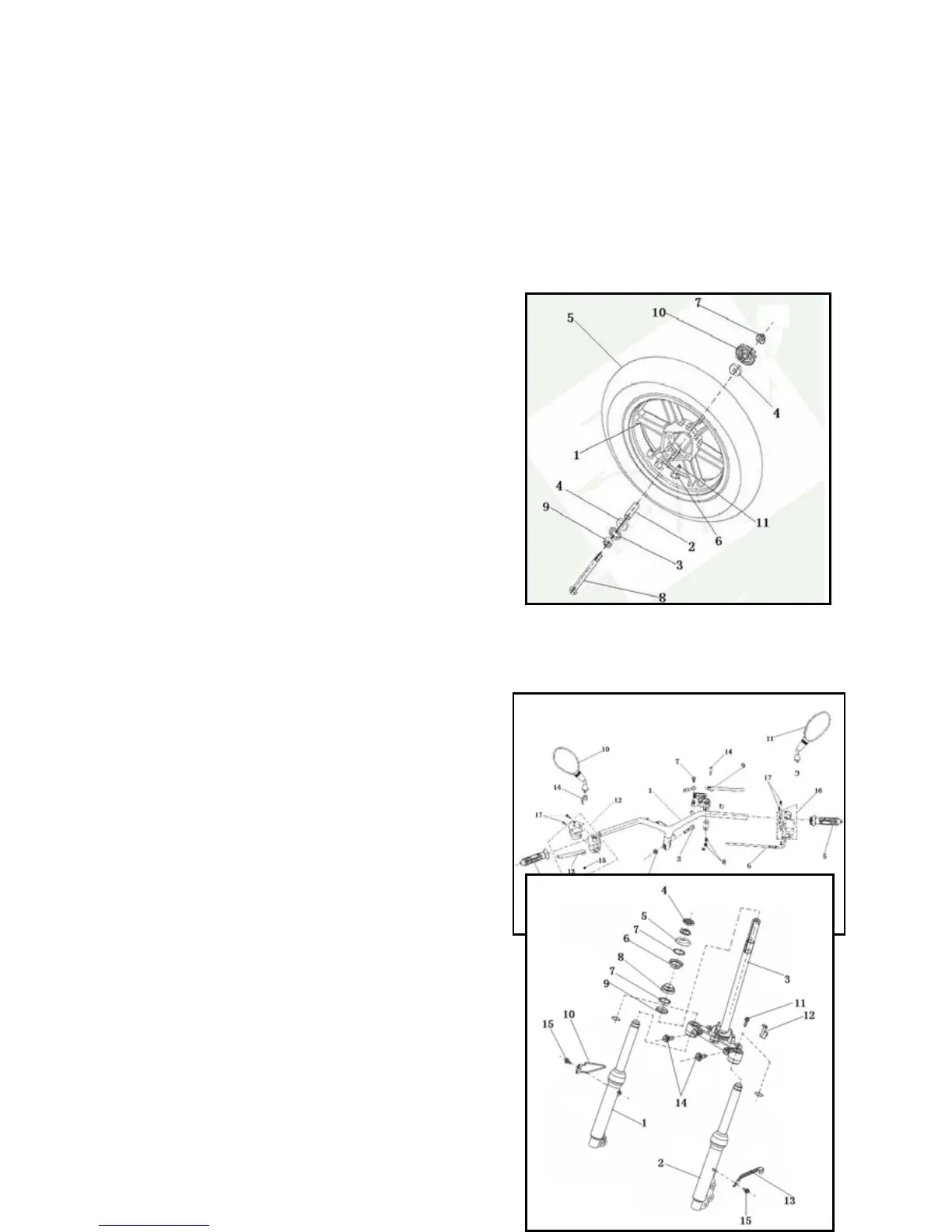

of the front wheel, dismantle the oil seal and bearing by using the oil seal puller and bearing puller respectively.

Note: the dismantled bearings should be replaced with new ones.

During the installation, smear grease lubricant on the bearings.

Then drive in the bearings by bearing installation tools.

*Attention

•The bearing must be punched in horizontally.

7.3.4 Installation

Mounting should follow the reversed procedure of dismantling

and pay attention to the following items:

lubricate front axle, components of gear seat, oil seal﹙interface﹚,

axle sheath, axle(6201-2RS), axle insulating sheath.

Recommended lubricant is grease of calcium radicle first.

Mount front wheel axle(8), front wheel, components of gear

seat(10), Bolts M12Χ1.25(7).

Make certain that the joint position is matched well when

mounting components of gear seat and odometer gear seat.

If those components are not jointed and locked tightly when

mounting, they will distort in the future.

Mount the braking cylinder to the front wheel hub.

Screw down the front wheel axle(as the figure of right side)

* Note:see P87 for figure RACE 50 for dismantling and

mounting front wheel.

Value of Torsion:

Blot for screwing down the front wheel axle 100-113

N·m

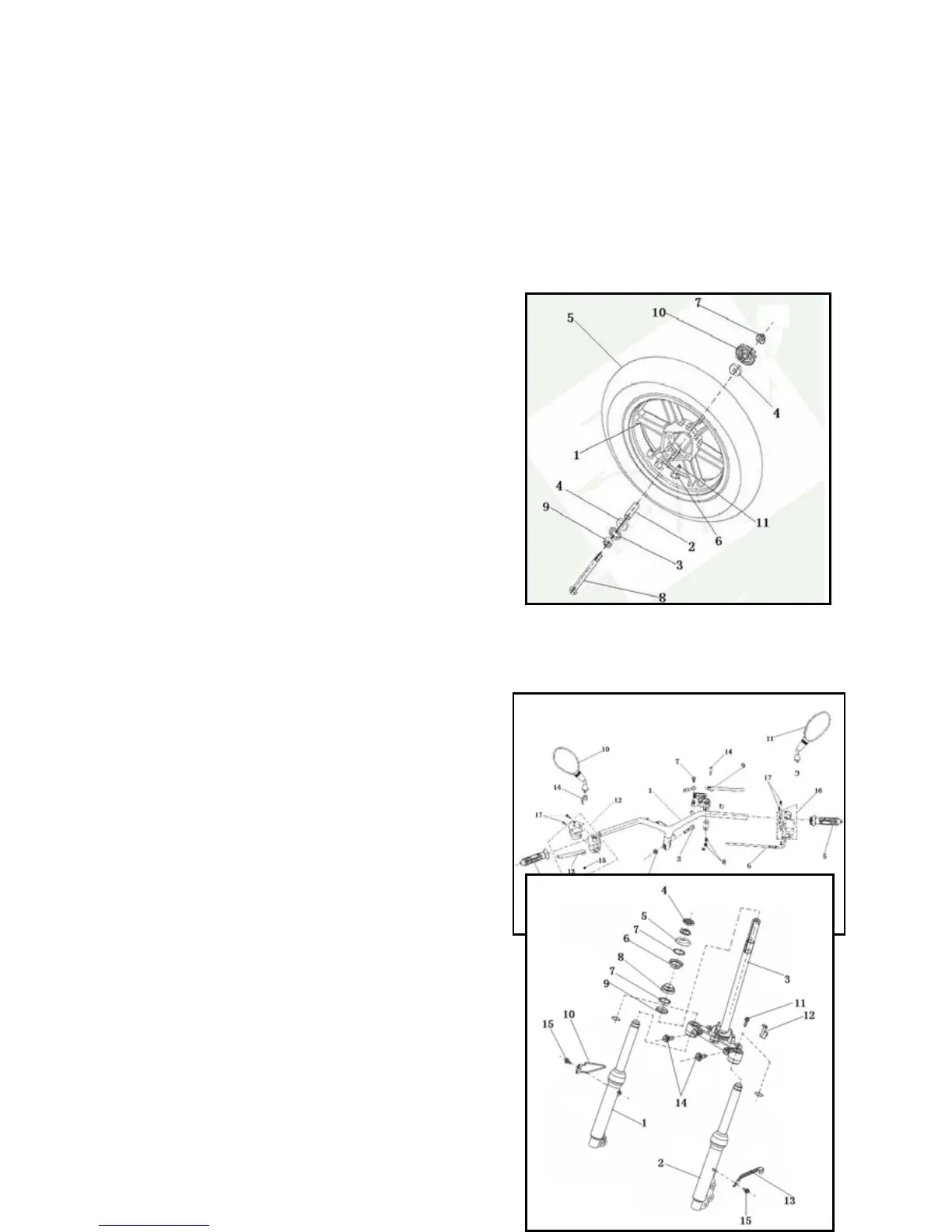

7.4 Steering bar

7.4.1 Dissemble

Remove components of back mirrors.

Remove bolts for fixing ornament lid of the upside and

downside cover of the steering bar.

Remove the upside ornament lid, and then remove meters.

Loading...

Loading...