94

must be cleaned away.

Inspect conduction of contact surfaces between other assemblies.

Confirm the armature shafts between each surface of the

commutator cannot be connected.

Inspect conduction of the housing of startup.

Confirm the terminal and housing of the startup electric

machinery cannot be connected. .

Inspect conduction of the terminal and electric brush.

If there is disorder, replace is with a new one.

Inspect conduction of the brush holder. If there is

conduction, replace is with a new one.

Measure the length of the electric brush.

Allowable limit:3mm(under the value, replace it)

Inspect whether the needle shaft in the front cover is flexible

in rotation and whether it is loosen when pressed in.

If there is disorder, replace is with a new one.

Inspect whether the oil seal is worn out or damaged.

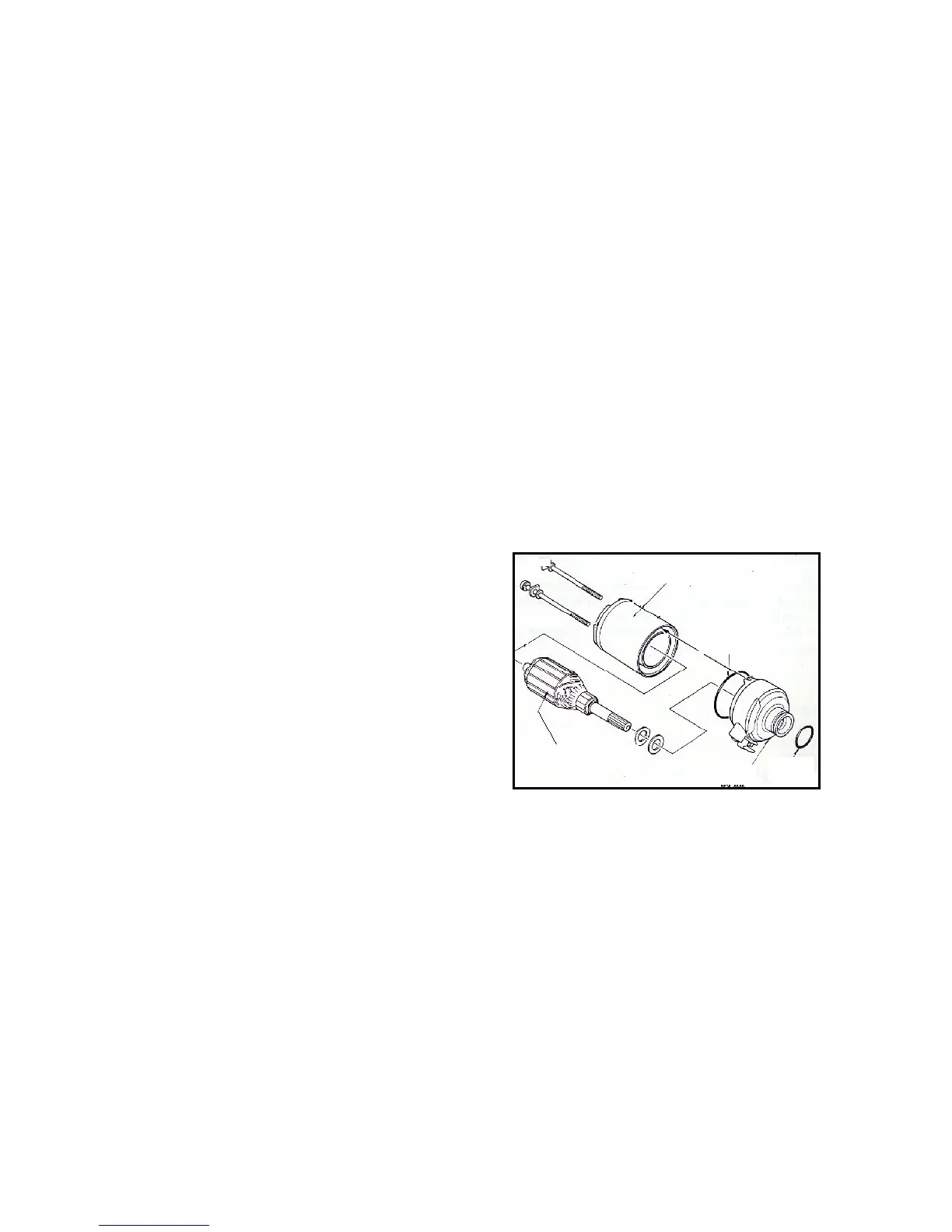

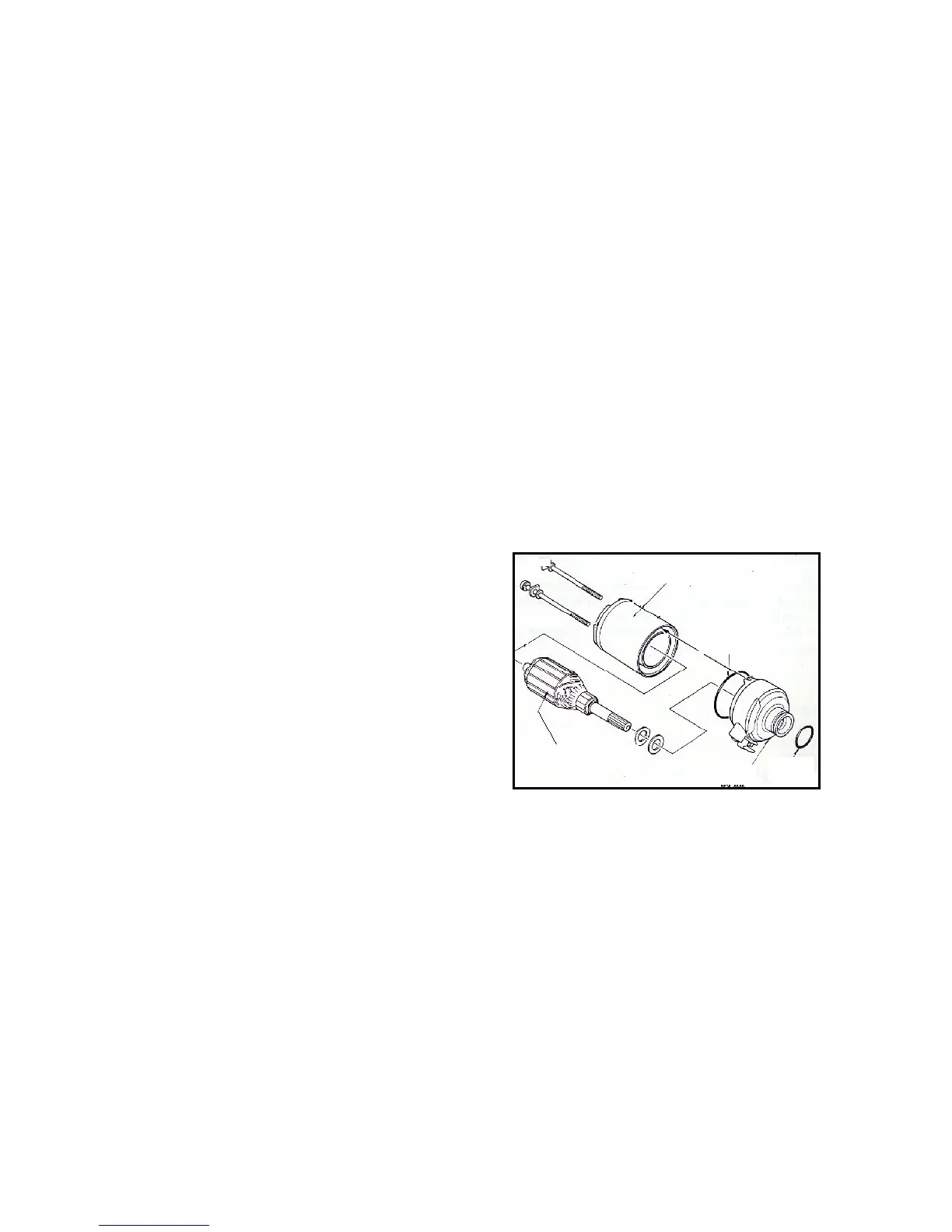

3.3.4 Assembly

Oil seal in the front cover and coating of grease.

Mount the electric brush on the brush holder.

Spread grease on the active parts of the electric brush ends.

Press all brushes in bracket and then install front cover of

electrode.

*Attention

•Take particular care that the contact surface of the electric

brush and armature can not be damaged.

•Take care in case the mounting shaft of the armature should damage the oil seal lip.

Put a new O-ring on front cover.

Install with the boss on motor casing engaging with the recess on front cover.

Screw the housing bolts.

*Attention

When the housing and front cover is assembled together, the

armature is easy to pull up with a magnet attracting the front

cover and can be put together with slight press down by hand.

3.3.5 Installation

Mount the wire of the startup electrical machinery and

Motor casing

O-ring

O-ring

Front cover

Loading...

Loading...