Operation

333587B 41

NOTE: The depressurization process does not

automatically stop. You need to manually stop

depressurization as described below.

3. Press the soft key to start the depressurization

process and to stop it.

4. Press the soft key for the platen or the

soft key for the valve to exit the depressurization

mode.

Priming Mode

The pump can be primed from the Run screen in Local

control mode during operation. If the pump is being

controlled by PLC Lockout, priming must be done

through CGM. See the Prime Diagram on page 87.

The steps are the same for the Ram and Tandem

systems. On Tandem systems, press the soft key,

if needed, to switch between Pump 1 and Pump 2.

NOTE: You are able to depressurize the platen and

valve on a pump while in priming mode.

1. On a Tandem system, open the Ball Valves (S) on

the Tandem Block (R).

1. Press the soft key to enter the pump priming

mode.

2. To control the flow of material, set your target

pressure and target flow in the fields that are

displayed above and to the right of the pump.

3. Press the soft key to start the priming process.

4. A timer is shown to the left of the priming mode icon

and counts down when the priming starts. The

default is 5 minutes but you can adjust the timer

setting to between 1 and 9 minutes. See Pump

Screen 2 - Pump Settings on page 27.

5. To manually stop the priming process at any time,

press the soft key. If you do not manually stop

the process, it will automatically stop when the timer

counts down to 0:00.

NOTE: If time has expired, you must press the soft

key again to resume priming. Do not press the soft

key until you have restarted the priming process.

6. Press the soft key to exit the priming mode.

NOTE: Refer to Load Material on page 35 for

information about priming and loading material into the

pump the first time after installation.

NOTE: Priming does not appear in the Job Log.

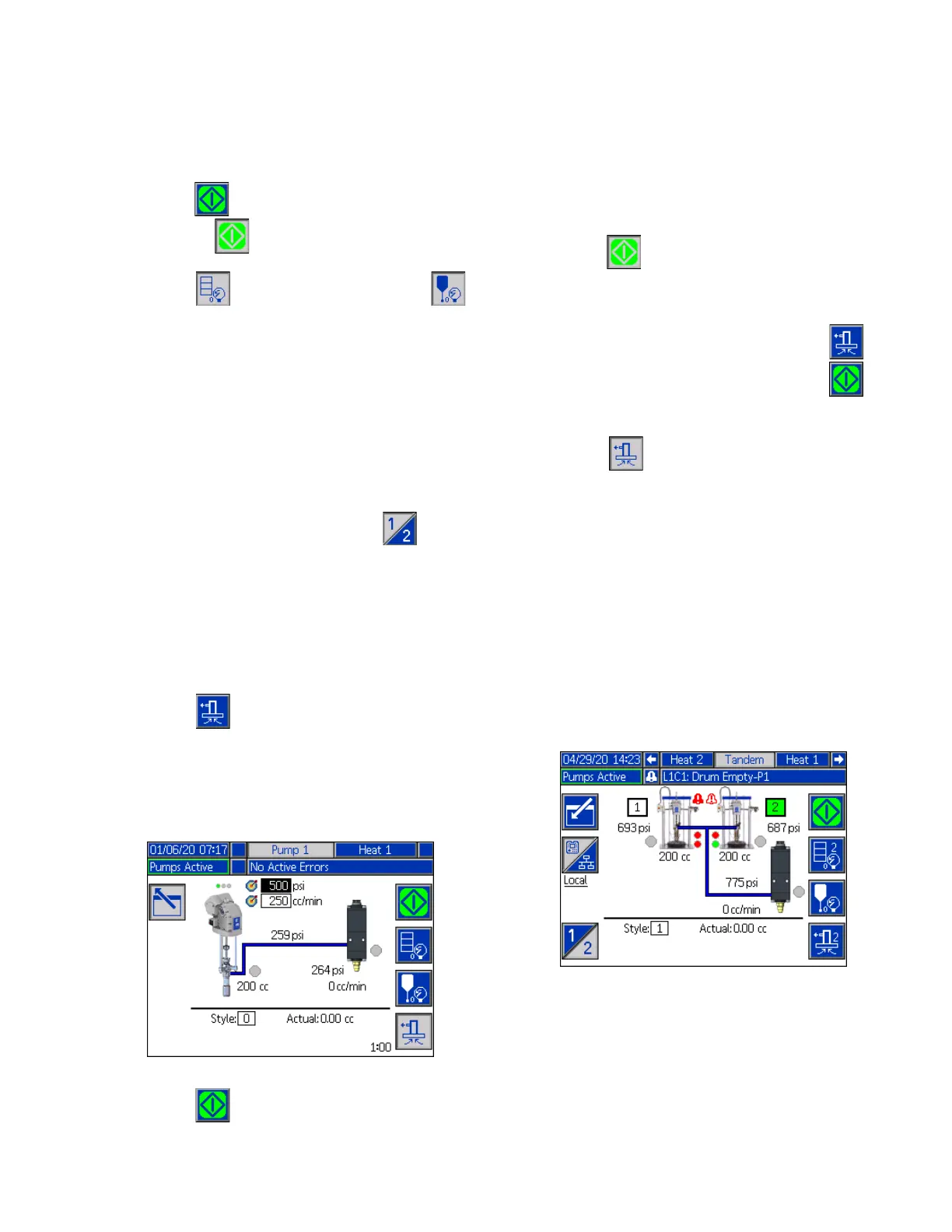

Low Level and Empty Level Indicators

The Tandem Run screen has low material level and

empty material level indicators. You can enable or

disable the sensors for these on Pump Screen 2 -

Drum Settings on page 27. These monitor the material

level in the drums.

The indicators normally show as green. When a low

level sensor on the ram is activated because material in

the drum is low, the top indicator for the pump turns red

and an error symbol appears next to the pump.

When an empty level sensor is activated on the ram, the

bottom indicator for the pump turns red and the error

symbol changes to the one selected for the empty level

sensor.

Loading...

Loading...