Appendix A - Advanced Display Module (ADM)

112 3A2098S

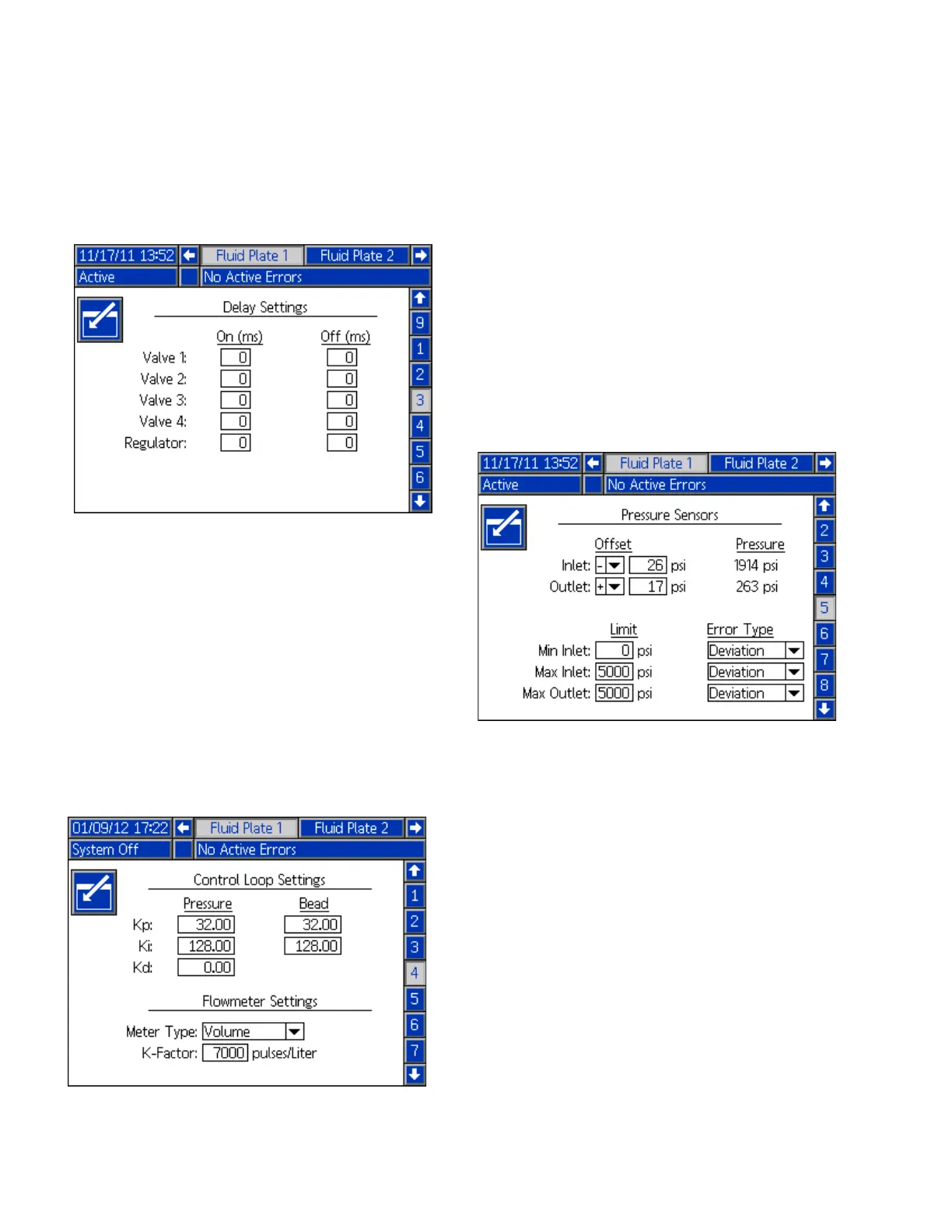

Fluid Plate x, Screen 3 (Delay Settings)

This screen enables users to set on and off delays (in

milliseconds) for each valve and the regulator

. For an

explanation of the on and off delays, refer to the On/Off

Delays section on page 43.

Fluid Plate x, Screen 4 (Control Loop and Flowmeter

Settings)

This screen enables users to set the meter type (volume

or mass) and the K-Factor for the flowmeter. Users can

also set the Kp, Ki, and Kd for the pressure control loop

as well as Kp and Ki for bead control loop.

NOTE: In systems without a flow meter, the flow meter

settings will be grayed out.

NOTE: It is recommended that these values not be

changed from the factory defaults of 32.00 for Kp,

128.00 for Ki, and 0.00 for Kd.

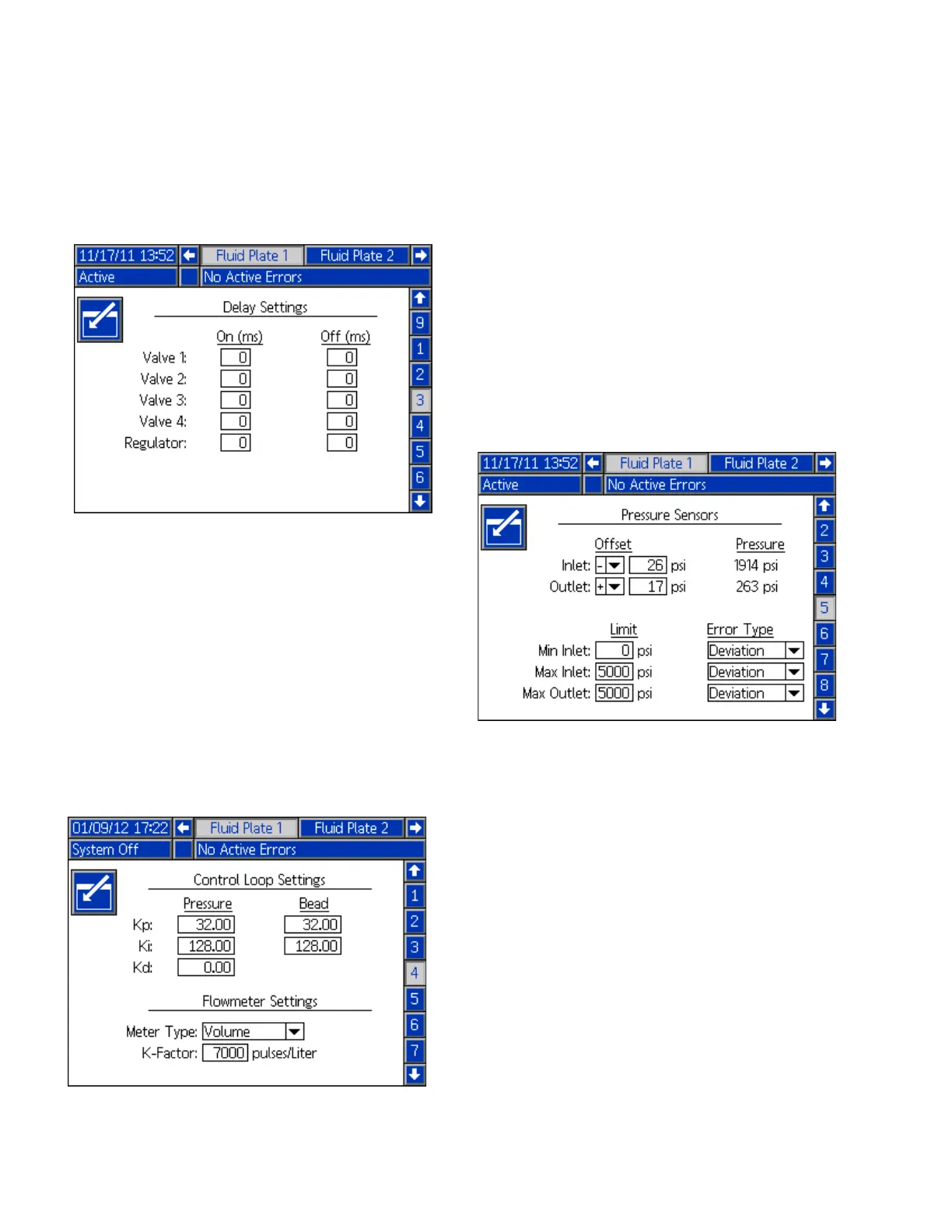

Fluid Plate x, Screen 5 (Pressure Sensors)

NOTE: Inlet sensor settings will be grayed out on this

screen for systems with heated fluid plates.

This screen enables users to:

• Set the offset for the inlet and outlet pressures.

NOTE: The offset value must be set to a non-zero

value before ‘-’ can be selected from the +/-

drop-down menu.

• Set the minimum and maximum pressure limits for

the inlet, and the maximum pressure limit for the

outlet.

• Set the error type (alarm or deviation) that will be

issued if the inlet and/or outlet pressure go outside

of the set limits.

Loading...

Loading...