Operation

3A2098S 45

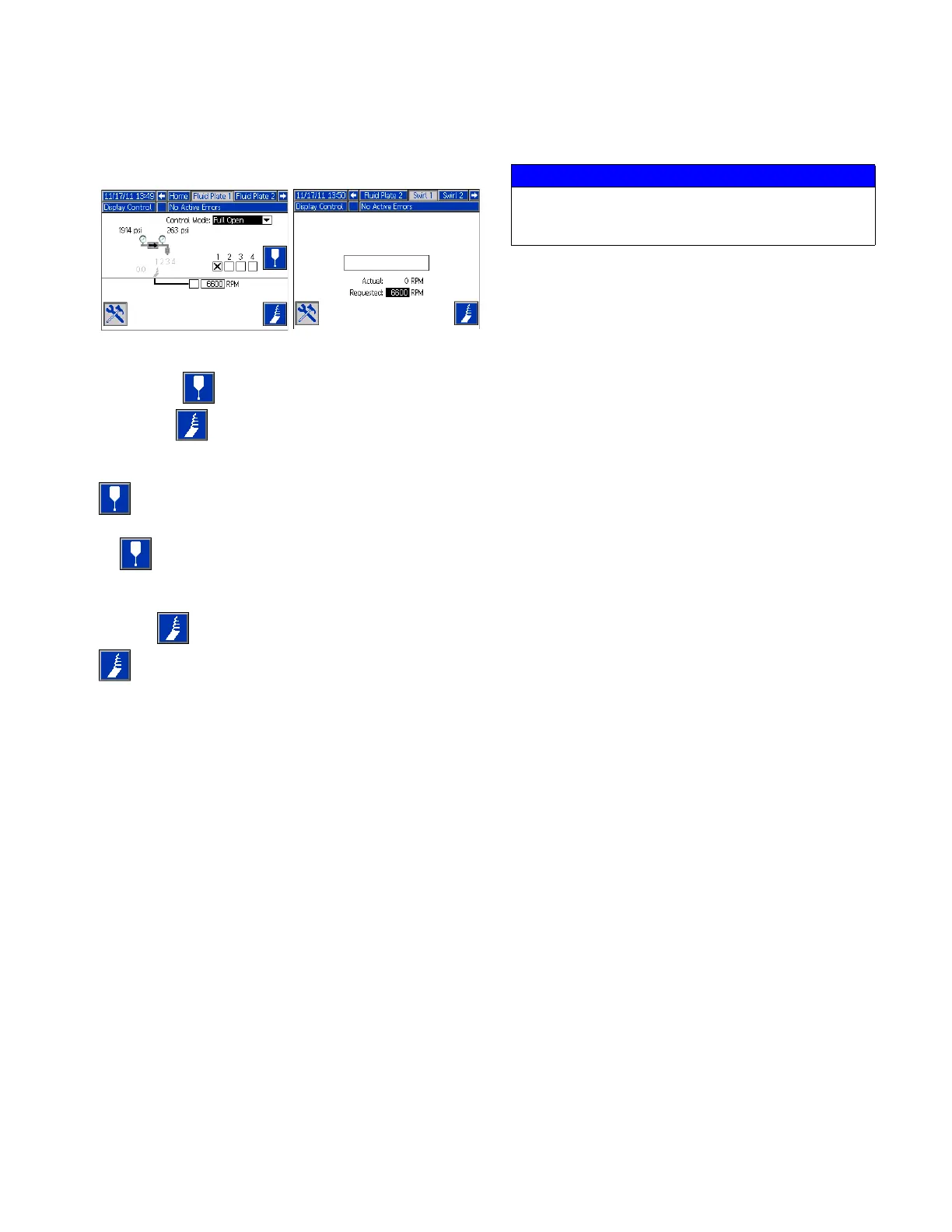

Maintenance Mode Operation

Operating from maintenance mode enables manual

dispensing ( ) and manually starting the swirl

dispenser ( ).

The system begins dispensing when the user presses

. Dispense parameters and duration depend on the

selected control. Dispensing continues for as long

as is pressed.

The system starts the swirl dispenser when the user

presses . The swirl dispenser continues to run until

is pressed again.

There is one maintenance screen for each installed fluid

plate and each installed Swirl. The maintenance

controls for the Swirl are shown on both the Swirl

maintenance screen and on the Fluid Plate

maintenance screen for the fluid plate where the swirl

dispenser is installed.

Verify System Operation

Use maintenance mode to manually check the operation

of the PCF system components before switching over to

automation control (normal operation). See Dispense

From Maintenance Screen, page 47, for instructions

on operating from maintenance mode.

NOTE: Perform the following procedures while in

maintenance mode.

Set Inlet Pressure

The inlet pressure reading should be in the range of

300 psi (2.1 MPa, 21 bar) to 500 psi (3.4 MPa, 34 bar)

above the outlet pressure reading under your highest

flow condition.

Follow steps in the supply system manual to set the inlet

pressure.

Feed System Pressure Drop

During material flow, the regulator inlet pressure

decreases. The amount the pressure decreases is the

amount of pressure lost between the feed pump and the

regulator inlet.

With high viscosity fluids, long line lengths, or small

diameter line sizes this pressure decrease can be

thousands of psi (hundreds of bar). This means that the

static pump pressure is set much higher than the

regulator needs at its inlet. To prevent excessive control

regulator wear or surging, a mastic fluid pressure

regulator is recommended on the feed line close to the

control regulator. The mastic regulator will suppress the

static feed pressure at the control regulator inlet.

Fluid Plate

Maintenance Screen

Swirl

Maintenance Screen

NOTICE

Inlet pressure beyond the recommended range

above will cause accelerated wear on the regulating

valve and the pump feed system.

Loading...

Loading...