System Setup

3A2098S 41

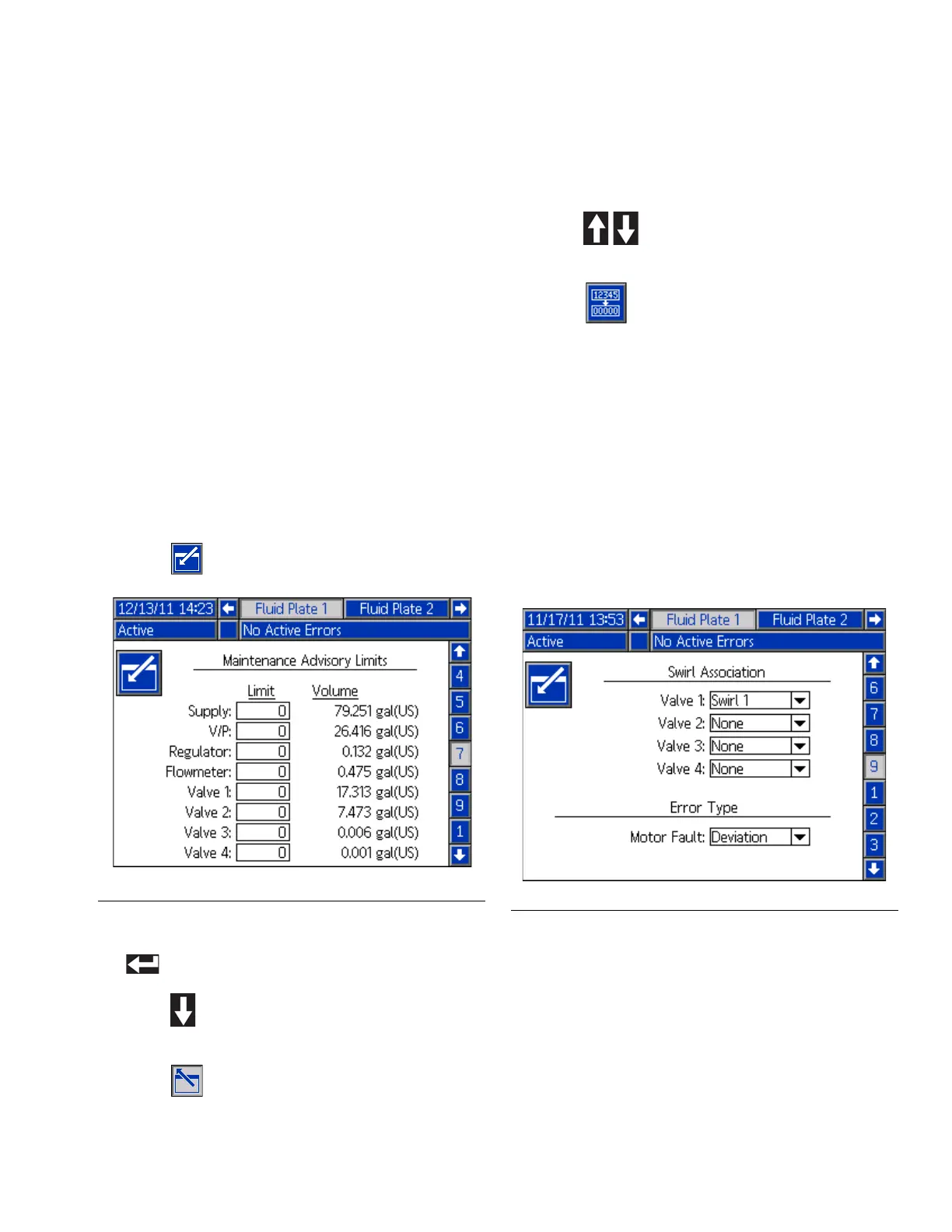

Setup Maintenance

Schedule/Parameters

Set the volume (or hours) limit that will trigger a

maintenance advisory for the fluid supply, Voltage to

Pressure (V/P) Transducer, fluid regulator, flow meter,

and all four valves.

NOTE: Hours is shown instead of Volume for fluid plates

without a flow meter.

The Volume (or Hours) column displays the current

totalizer value. If this value exceeds the set limit, the

value will turn red and a maintenance advisory is issued.

See Fluid Plate x, Screen 7 (Maintenance Advisory

Limits), page 113, for more information about

maintenance totalizers.

To set limits:

1. With the system in setup mode, navigate to the Fluid

Plate x, screen 7 (Maintenance Advisory Limits).

2. Press to access the fields to make changes.

3. Enter the desired limit for the air supply and press

to enter the selection.

4. Press to move to the next field. Repeat Step 4

for each field.

5. Press to exit edit mode.

To reset a totalizer value:

1. Follow Steps 1-3 of To set limits: to make changes

in

Fluid Plate x, screen 7 (Maintenance Advisory

Limits)

.

2. Press to scroll to the system component to

reset.

3. Press to reset the value.

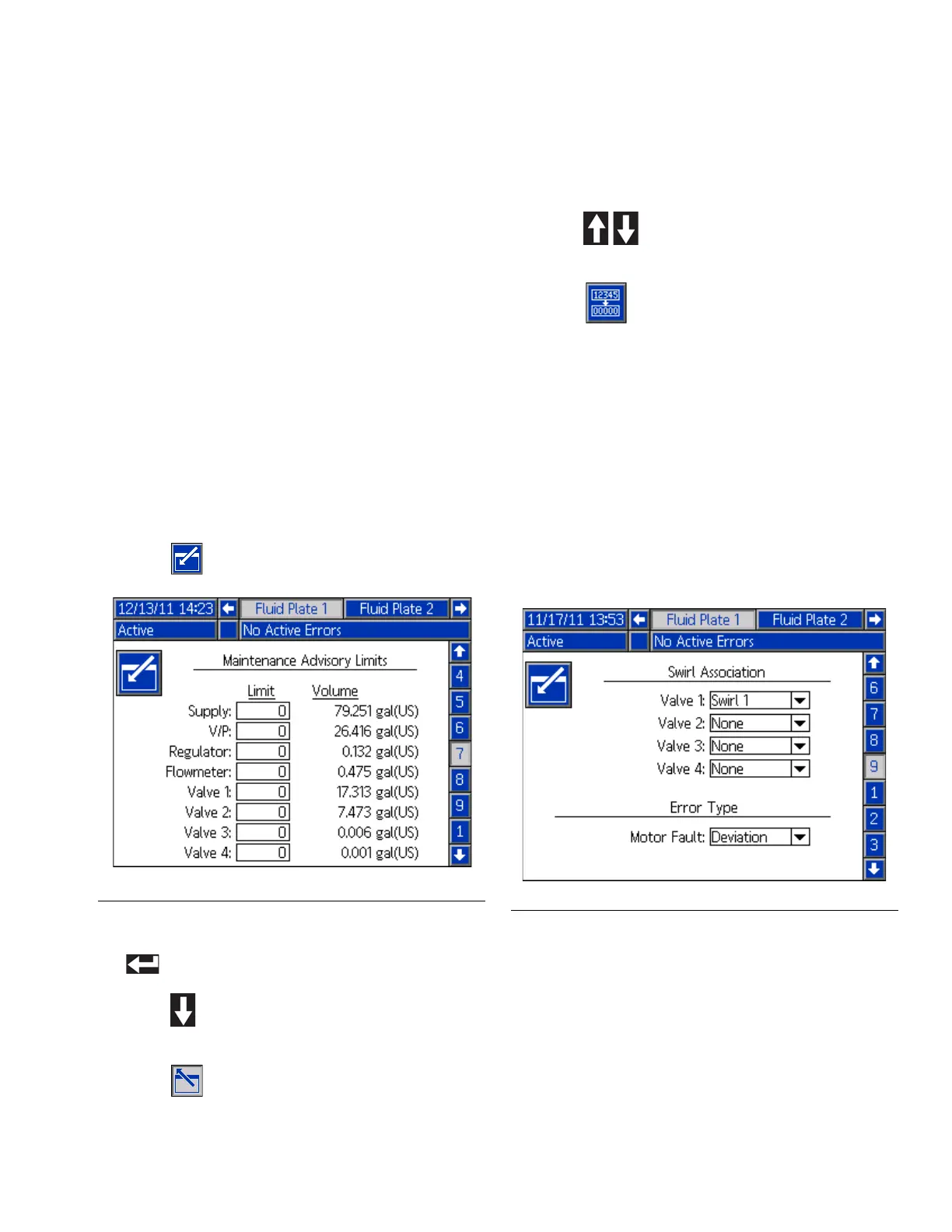

Configure Valve to Swirl

Association and Motor Error

Type

Define which Swirl number is installed on which

dispense valve.

Set the error type (alarm or deviation) that will be issued

if a motor fault occurs. When an alarm occurs, the fluid

plate stops dispensing. When a deviation occurs, the

fluid plate will continue dispensing.

F

IG. 29

FIG. 30

Loading...

Loading...