Maintenance

80 3A2098S

Maintenance

Prior to performing any maintenance procedures, follow

the Pressure Relief Procedure on page 61.

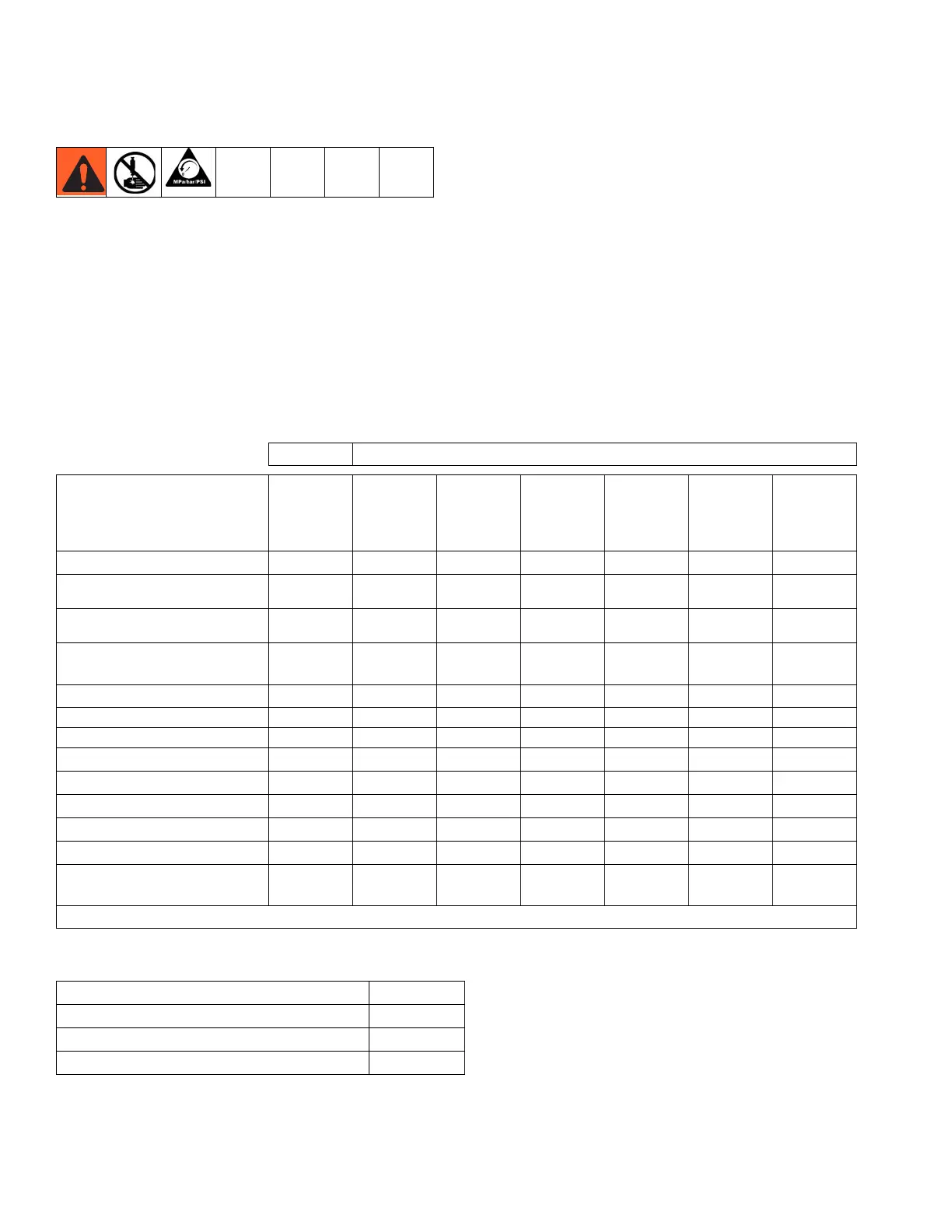

Maintenance Schedule

The following tables list the recommended maintenance procedures and frequencies to operate the equipment

safely. The maintenance is divided between mechanical and electrical tasks. Maintenance must be performed by

trained personnel per this schedule to assure safety and reliability of the equipment.

Mechanical

Electrical

* Check Component Manual for more detailed maintenance information.

Operator Maintenance Person

Task Daily Weekly Monthly

3-6

months

or

125,000

cycles

18-24

months

or

500,000

cycles

36-48

months

or

1,000,000

cycles

7000

hours

Inspect system for leaks

Depressurize fluid, after opera-

tion

Remove heat from system,

after operation

Inspect filter (234967) bowls

and drain

Check hoses for wear

Check/tighten fluid connections

Check/tighten air connections

Lubricate dispense valves*

Rebuild regulator*

Rebuild dispense valve*

Replace air filter

Replace Solenoid

Replace Voltage to Pressure

(V/P) Transducer

* Check component manual for more detailed maintenance information.

Task Weekly

Check cables for wear

Verify cable connections

Verify operation of “System Stop” button

Loading...

Loading...