Pressure Relief Procedure

3A2098S 61

Pressure Relief Procedure

1. Shut off the fluid supply to the fluid plate assembly.

2. Place a waste container beneath the dispense

valve.

3. In maintenance mode, select Full Open Dispense

Mode, which opens the regulator and dispense

valve. Press the manual dispense button until

the fluid flow stops.

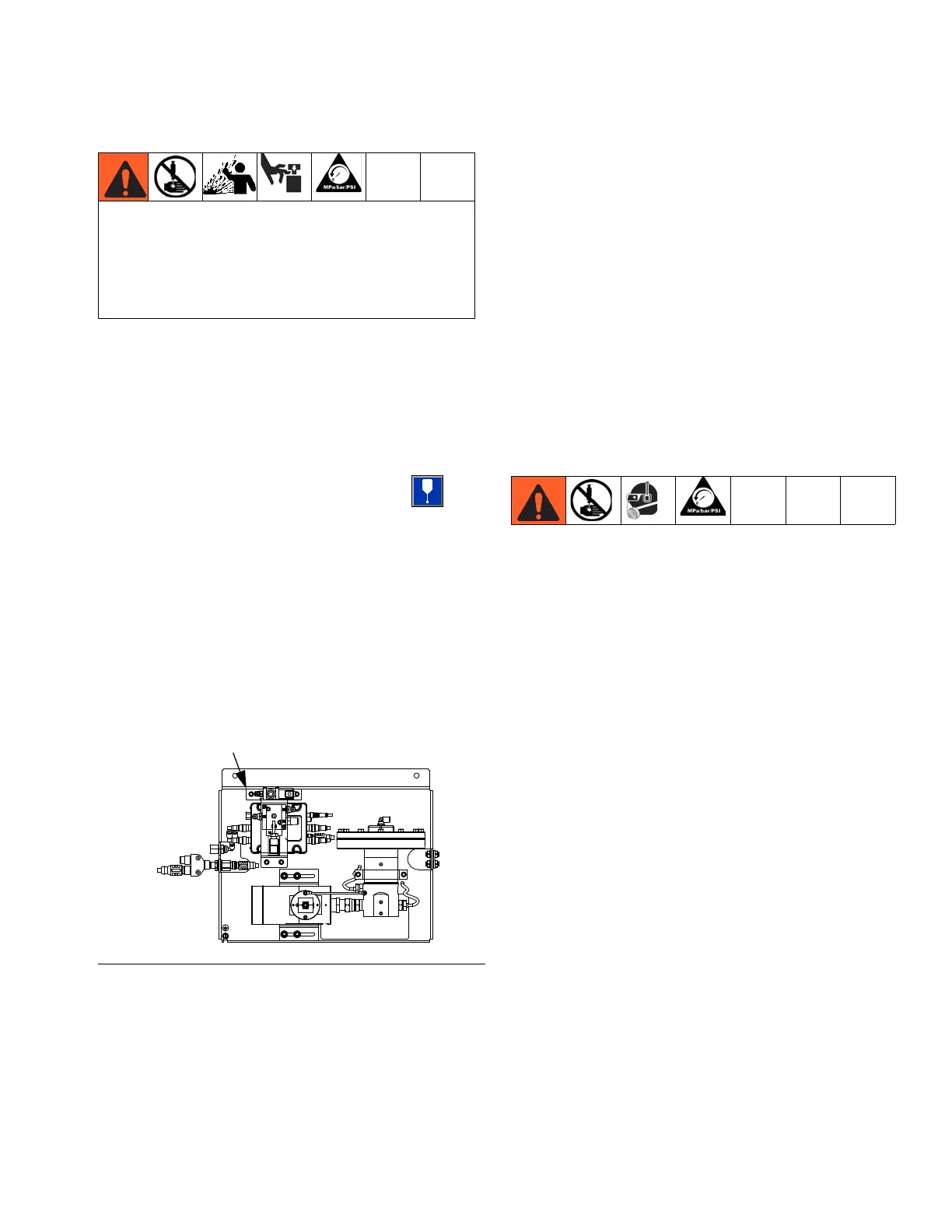

4. If the dispense valve cannot be actuated from the

control center, refer to F

IG. 39 and perform the

following steps to open the dispense valve and

relieve fluid pressure:

a. Manually actuate the plunger on the solenoid to

open all dispense valves attached to this fluid

plate and relieve fluid pressure. See F

IG. 39.

b. Continue actuating the plunger until all pressure

is purged from the system between the needle

and the dispense valves attached to this fluid

plate before proceeding to the next step.

5. For systems with multiple fluid plates, repeat

previous steps for other fluid plates.

6. Shut off air to the fluid plate.

7. Place a waste container below the air filter

assembly then open drain valve on the air filter

assembly. Close drain valve once air is relieved.

8. Turn main power switch on control panel to the OFF

position.

9. If you have followed the previous steps and suspect

that a valve, hose, or dispense nozzle is clogged or

that pressure has not been fully relieved, very slowly

remove the dispense tip, clean the orifice, and

continue relieving pressure.

10. If this does not remove the clog, cover the hose end

coupling with a rag then very slowly loosen the hose

end coupling to relieve pressure gradually, then

loosen the coupling completely. Clear the valves or

hose. Do not pressurize the system until the block-

age is cleared.

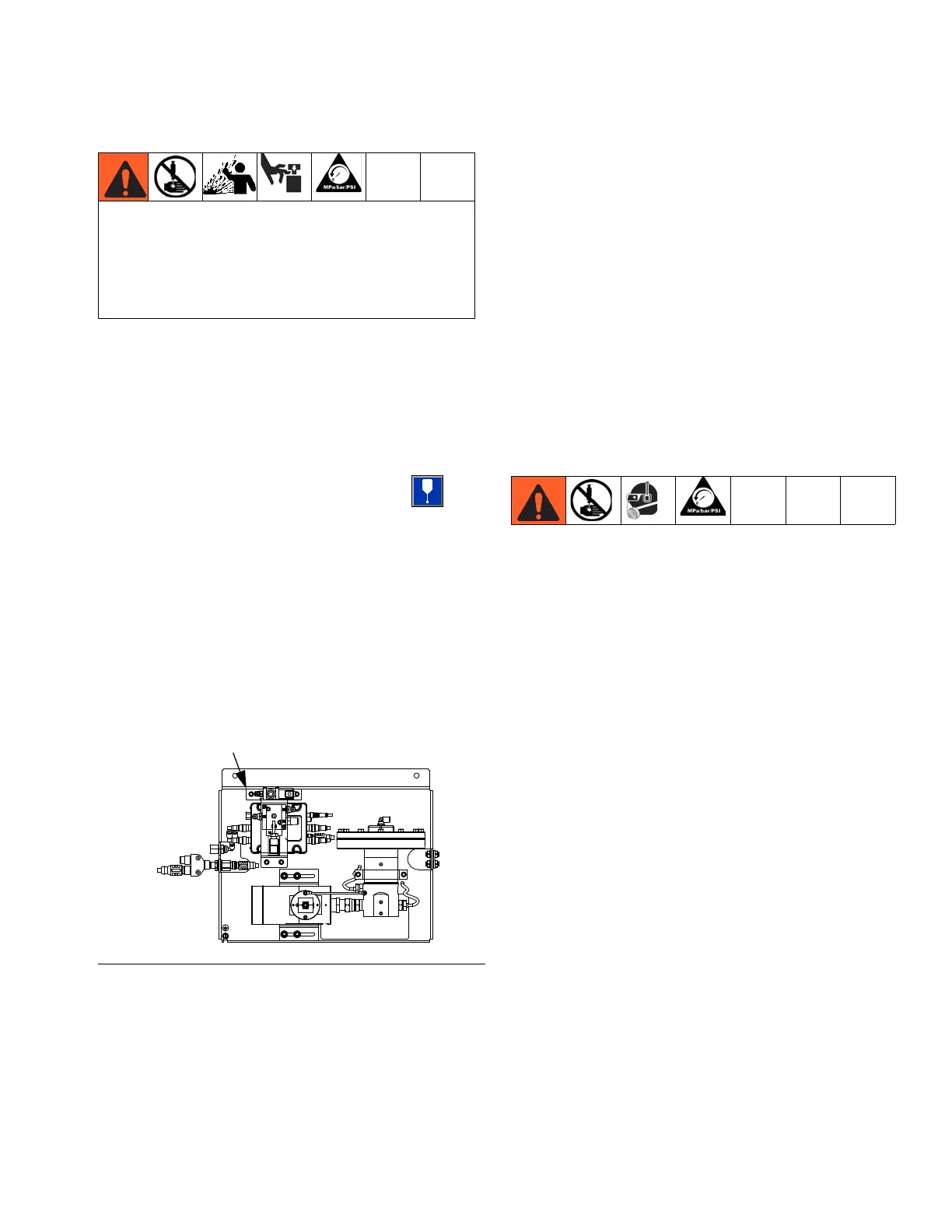

The equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief Pro-

cedure when you stop dispensing and before clean-

ing, checking or servicing the equipment.

F

IG. 39: Dispense Valve Air Solenoid

Dispense Valve Air Solenoid

Loading...

Loading...