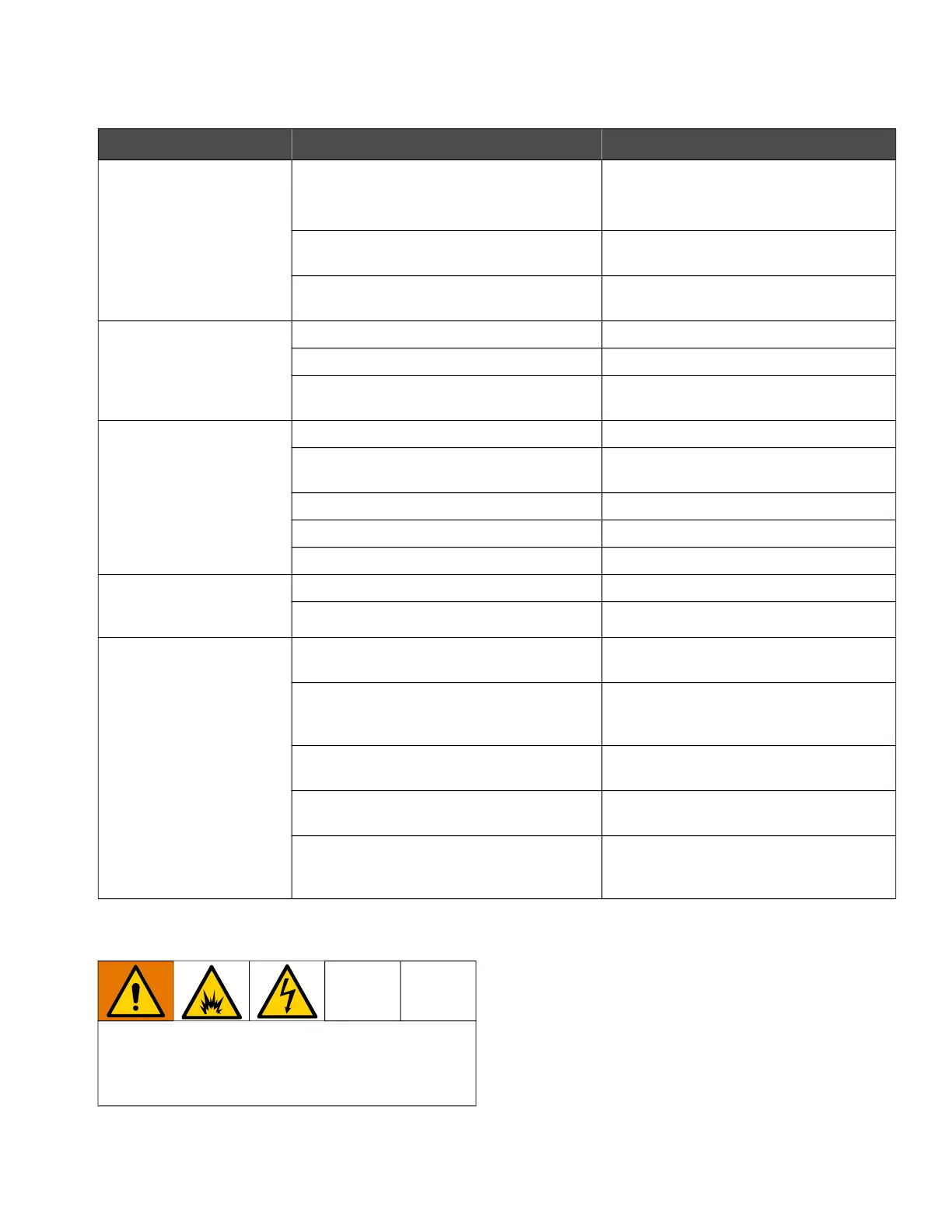

Troubleshooting

3A8572B 31

Equipment stalled, will not

cycle

Fluid line clogged or valves closed. Inspect; clear.

Open valves downstream of the

equipment.

Motor or controller wired improperly. Wire per instructions in your related motor

manual. See Related Manuals, page 2.

Leak sensor tripped. Check diaphragm for rupture or incorrect

installation. Repair or replace.

Reduced performance Fluid line clogged. Inspect; clear.

Checks are sticky or leaking. Clean or replace.

Diaphragm (or backup diaphragm, if

applicable) ruptured.

Replace.

Air bubbles in fluid Fluid line is loose. Tighten.

Diaphragm (or backup diaphragm, if

applicable) ruptured.

Replace.

Loose manifolds. Tighten manifold fasteners or clamps.

Damaged seats or seals. Replace seats or seals.

Loose diaphragm shaft fastener. Tighten.

Fluid leaking from lower

ports on the equipment or

fluid on the floor.

Loose diaphragm shaft fastener. Tighten.

Diaphragm rupture. Leak in the equipment. Replace.

Equipment suddenly stops

operating or shuts down.

Ground fault circuit interrupter (GFCI)

tripped.

Remove controller from the GFCI circuit.

Poor supply power. Check connections. Determine and fix the

source of the problem with the supply

power.

Exceeded operational parameters. See Troubleshoot LED Indicator Event

Errors, page 26, for event codes.

Leak sensor* alert. Leak detected in the

equipment.

Check the diaphragm for rupture or

incorrect installation. Repair or replace.

The leak sensor* disconnected. Ensure the leak sensor is properly

installed. See your related leak sensor

manual.

* A leak sensor is not provided with the equipment. Accessory kits are available (purchase separately). See Related Manuals,

page 2.

Problem Cause Solution

‡

Do not modify or repair explosion proof joints.

Modifying explosion proof joints will invalidate the

Hazardous Location Certification of the equipment

and may produce an explosion hazard.

Loading...

Loading...