Repair

36 3A8572B

Repair the Overmolded

Diaphragms

Required Tools:

• 10 mm socket wrench (for all i30 (QTC) models, i80

(QTD) plastic models, and i120 (QTE) plastic

models)

• 13 mm socket wrench (for i80 (QTD) metal models

and i120 (QTE) metal models)

• Torque wrench

• 25 mm open-end wrench

• Lubriplate

®

Synxtreme HD-2 grease (or equivalent

NLGI Grade 2 synthetic grease with calcium

sulfonate base)

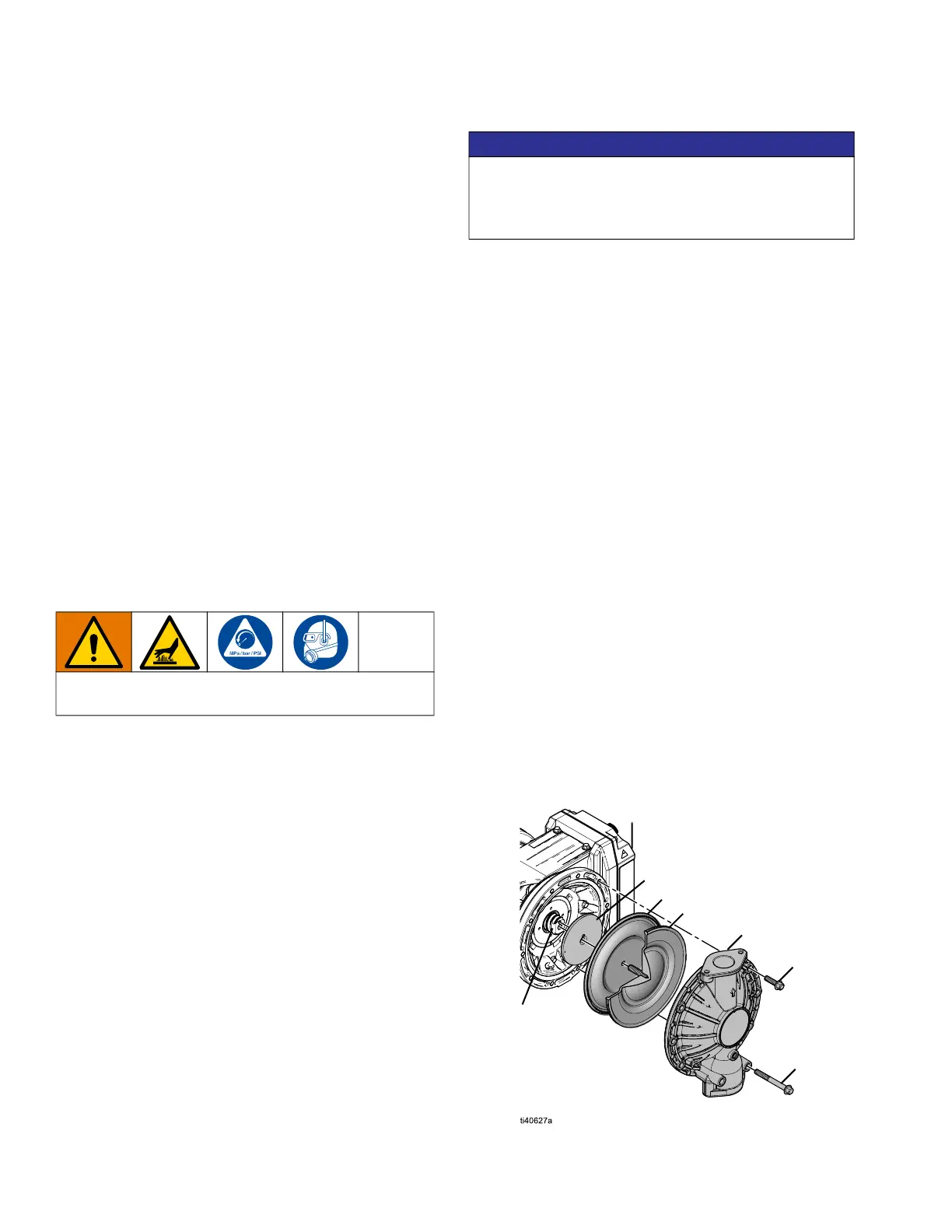

See F

IG. 18–FIG. 20.

NOTE: Lubricate the motor rotor when replacing

diaphragms. See your related motor manual. See

Related Manuals, page 2.

Disassemble the Overmolded Diaphragms

1. Follow Prepare Equipment for Repair, page 32.

2. Follow Disassemble Check Valves, page 33.

3. Remove all fasteners (7, 7b, if applicable) from the

fluid covers (3). Remove the fluid covers (3).

4. Firmly grip the outer edge of a diaphragm (13) to

hold in place. At the same time, securely grip the

outer edge of the opposite diaphragm (13) and

rotate counterclockwise to loosen. Remove the

diaphragm (13).

NOTE: If needed, leave one fluid cover fastened.

With one diaphragm exposed, use both hands to

loosen the exposed diaphragm.

NOTE: Do not remove the diaphragm shaft (1a)

from the motor (1).

5. Remove the remaining diaphragm (13).

If the first loosened diaphragm (13) is on the

side of the shaft (1a) with the wrench flat:

a. Use an applicable wrench to firmly hold the flat

of the shaft (1a) in place. At the same time,

securely grip the outer edge of the opposite

diaphragm (13) and rotate counterclockwise to

loosen.

If the first loosened diaphragm (13) is opposite

the wrench flat on the shaft (1a):

a. Follow the procedure to lubricate the rotor in

your related motor manual to access the flat of

the shaft (1a). See Related Manuals, page 2.

b. After the flat of the shaft (1a) is accessible, use

an applicable wrench to firmly hold the flat of

the shaft (1a) in place. At the same time,

securely grip the outer edge of the opposite

diaphragm (13) and rotate counterclockwise to

loosen.

6. Clean and inspect parts for wear or damage.

Replace parts as needed.

7. Lubricate the rotor. See your related motor manual.

See Related Manuals, page 2.

FIG. 18: Overmolded Diaphragms

To avoid severe burns, do not touch hot fluid or hot

equipment.

NOTICE

To avoid damage to the rotor or equipment, do not

remove the shaft (1a) from the motor (1). Removing

the shaft will cause the rotor balls to dislodge from

the rotor and the rotor will not function properly.

3

7

7b

13

1

1a

21

14

Loading...

Loading...