Troubleshooting

4.Checkfunctionalityofthedirectionalvalve

(207).

a.Conrmthatthedirectionalvalvecable

isconnectedproperlyfromHCMport15

tothedirectionalvalvebody(207)and

isnotdamaged.Inspectwiringinside

thecoverofthedirectionalvalve.See

ElectricalSchematics,page105.

b.Duringoperation,thedirectionindicator

lightsonthedirectionalvalvebody(207)

shouldswitchonbasedonthevalvethat

isopen.

c.Turnonthemotorandstallthepumpsat

thelowestpressuresetting(compensator

knobturnedfullycounter-clockwise).

ThepumpwilltravelineithertheAor

Bdirectionuntilthepressuresettingis

reached.

d.Identifythesolenoidthatisoperating

byviewingthedirectionindicatorlights

onthecoverofthedirectionalvalve

(207).Measurevoltageacrossthe

associatedterminalstodetermineif

propervoltageisreachingthevalve

(approximately200to240VAC).See

ElectricalSchematics,page105,and

thetablebelow,toidentifytheproper

terminalstomeasureacross.

e.Triggereachproximityswitch(211)with

theshaftofascrewdriver,conrming

eachsolenoidwithinthedirectionalvalve

(207)operatesasdescribedintable

below.

f.Ifoneorbothsidesarenotoperating

properly,accordingtothetable,rst

reconrmwiringtodirectionalvalve

(207)perElectricalSchematics,page105,

thenreplacedirectionalvalve(207).

For For

For

given given

given

pump pump

pump

movement movement

movement

direction: direction:

direction:

Pump Pump

Pump

driving driving

driving

left left

left

(toward (toward

(toward

park park

park

position) position)

position)

Pump Pump

Pump

driving driving

driving

right right

right

(away (away

(away

from from

from

park park

park

position) position)

position)

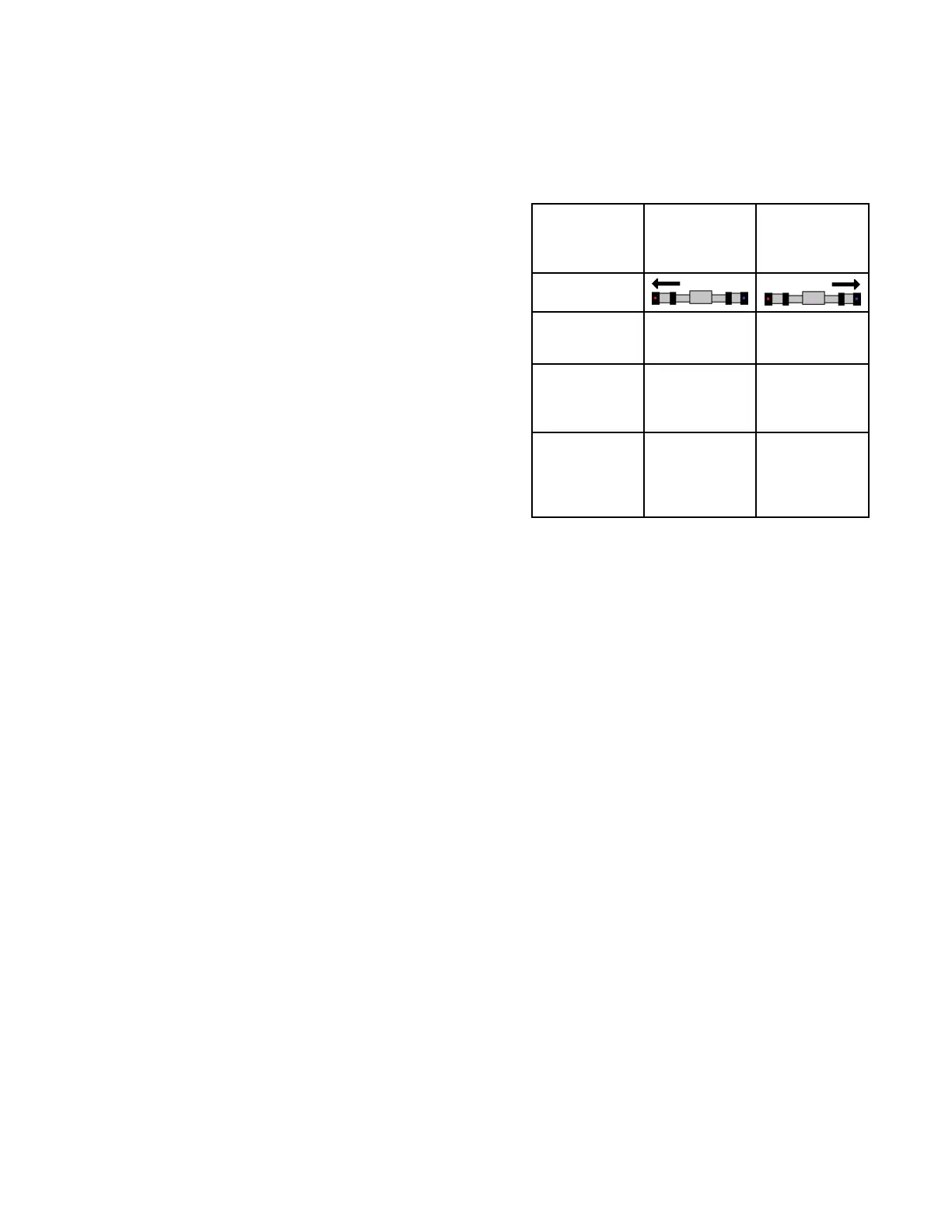

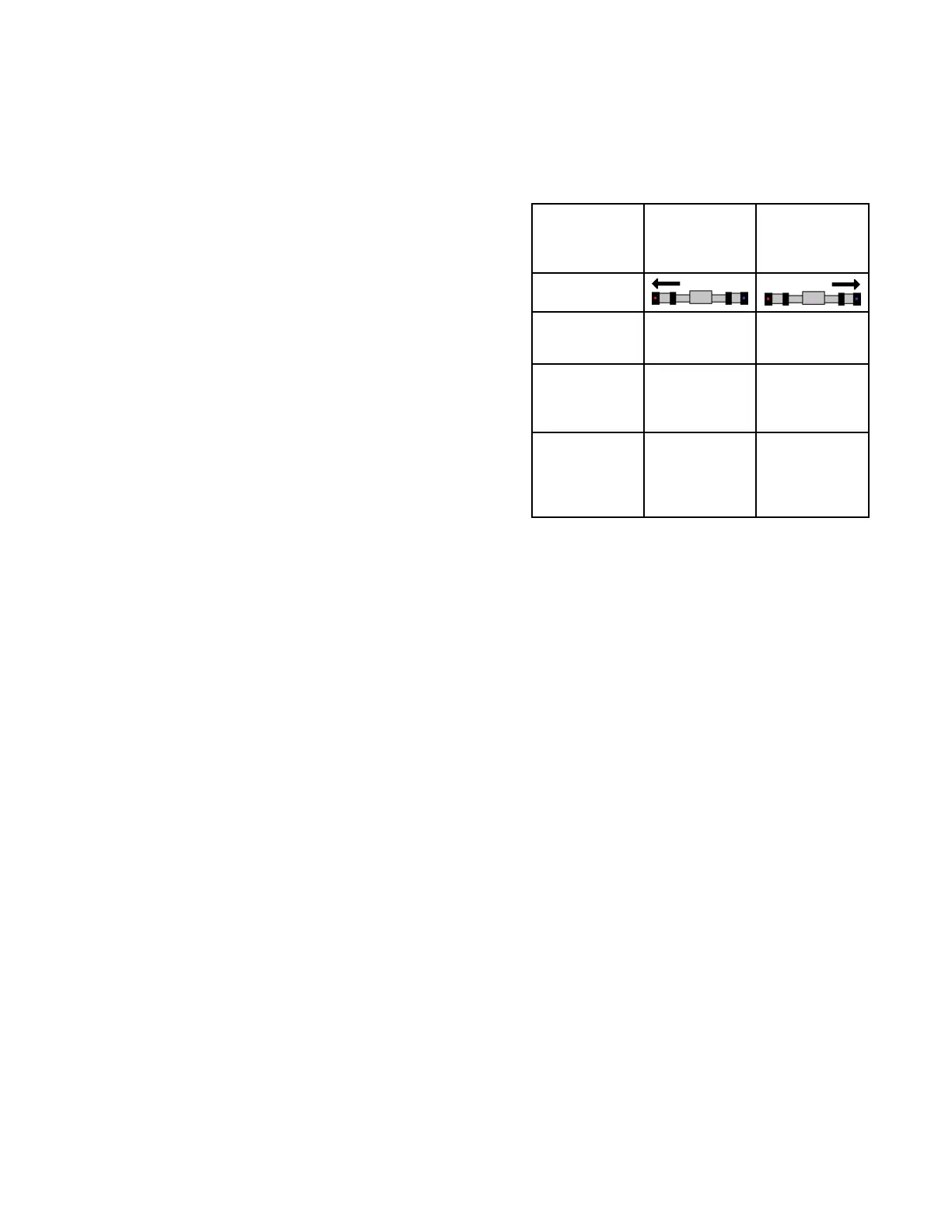

ADM

indicates

Indicatorlight

ondirectional

valvecover

Leftarrow,

labeled“b”

Rightarrow,

labeled“a”

Last

proximity

switch

triggered

Rightside

proximity

switch

Leftside

proximity

switch

Terminalsin

directional

valve

energized

Terminals

associated

withredand

orangewires

Terminals

associated

withblack

andwhite

wires

NOTE: NOTE:

NOTE:

Fordiagnosticpurposes,itispossible

tomanuallyoverridethedirectionalvalve

byusingasmallscrewdrivertodepressthe

buttoninthecenterofeitherdirectional

valveendcap.Depressingthebuttoninthe

rightendcapshouldcausethepumpto

traveltotheright.Depressingtheleftbutton

shouldcausethepumptotraveltotheleft.

5.Ifyouhavedeterminedthatthecauseis

noneofthepreviouspossiblecauses,check

foraloosepistonpackingretainingbolt.

Thiscausesthepistontocontacttheinner

faceofthepumpinletangebeforethe

switchingplateactivatestheproximity

switch.Shutdowntheunitanddisassemble

theappropriatepumpforrepair.

Following Following

Following

step step

step

1, 1,

1,

if if

if

the the

the

proximity proximity

proximity

switch switch

switch

indicating indicating

indicating

lights lights

lights

do do

do

not not

not

light: light:

light:

6.Checkforlooseorfaultyproximity

switchcableorconnections.Conrmthe

connectionstotheproximityswitchesare

tightandinternallyfreefromoilandother

contaminates.

7.Swapthecablestotheproximityswitchesto

seeiftheproblemfollowstheswitchorisin

thecable.Replaceeitherthefailedswitch

orthecable.

8.ReplacetheHCM.SeeReplaceHCM,page73.

334946J

43

Loading...

Loading...