Do you have a question about the GRAVOGRAPH L-Solution 700 and is the answer not in the manual?

Details EC marking and EEC directives like security, EMC, and low voltage.

Covers mains plug connection to a neutral socket and safety regulations.

Specifies compliance with safety standards EN 292-1, EN 292-2, and EN 12626.

Lists EMC standards and warns about potential radio interference in domestic environments.

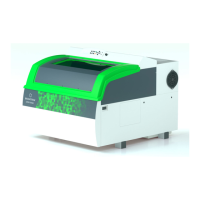

Introduces the L-SOLUTION machine and its innovative design features.

Lists essential warnings and prohibited actions for safe operation.

Details the steps for safely unpacking the machine, including lifting and guard removal.

Lists all items included in the machine's packaging, such as the machine, CD-ROMs, and tool box.

Explains the machine's LASER classification and the function of safety interlocks.

Describes the safety labels affixed to the LASER system and their locations.

Identifies and describes the components visible on the front of the LASER machine.

Details the various connection sockets and ports located on the rear of the machine.

Guidelines for placing the machine in a suitable environment and ensuring proper ventilation.

Requirements for proper ventilation and fume extraction systems for safe operation.

Specifies the requirements for the optional air compressor for the air assist function.

Details the minimum PC hardware and software specifications needed for the LASER system.

Provides recommendations on font types (True Type) for optimal engraving quality.

Guidelines for power connection, ensuring proper voltage and avoiding electrical interference.

Step-by-step instructions for connecting the machine's cables, including exhaust and power.

Procedures for safely starting, stopping, and troubleshooting the machine.

Instructions for connecting the LASER machine to a computer for data transfer.

Specific steps for connecting the L-SOLUTION to a PC using the USB port.

Specific steps for connecting the L-SOLUTION to a PC using the parallel port.

Specific steps for connecting older L-SOLUTION models via the serial port.

Guide to configuring machine settings such as language and display unit.

Step-by-step guide for installing the LASER machine's printer driver on Windows.

Configuration steps for establishing serial communication between PC and machine.

Explanation of the various controls and tabs within the printer driver interface.

Adjusting power, speed, resolution, and engraving modes within the LASER settings.

Settings for rubber stamps, wood engraving, and handling engraved objects.

Handling bitmaps, saving/opening jobs, defining plates, and managing graphics.

Configuration options for optional accessories like cylinder attachment and exhaust.

General advice for configuring graphics software to work with the LASER system.

Mapping colors to LASER power settings for engraving and cutting.

How the driver interprets graphic elements for cutting (vector) and engraving (raster).

Methods to reduce engraving time by optimizing graphic orientation and color usage.

Guidelines for handling monochrome, grayscale, and color bitmaps for engraving.

Explains the machine's main parts: DC supply, UC board, PUI board, control panel, LASER tube, motion system.

Details on indicator lights, buttons, LCD display, and how to navigate the menu system.

How to access and use Parameters, File, Info, and Configuration menus for engraving jobs.

Setting up inputs/outputs for integrating the machine into an automated production line.

Initial steps including powering on the computer and machine, and creating the engraving graphic.

Configuring driver settings and transferring the graphic file to the LASER system.

Loading material onto the engraving table and adjusting the LASER focus.

Initiating the engraving process and safety checks during operation.

Steps for safely removing finished material and preparing for the next job.

Solutions for problems encountered during serial and parallel data transmission.

Description and use of the attachment for engraving cylindrical objects like mugs.

Accessory allowing cylindrical objects to be engraved at a slant.

Components to support material during cutting, minimizing surface contact area.

Details on the compressor kit for providing compressed air to the air assist function.

A table that supports material and aids in smoke removal during cutting.

Warnings on material handling, fume hazards, and prohibited materials like PVC.

Advice on adjusting power, speed, and PPI based on material properties.

A list of materials compatible with the LASER system for engraving and cutting.

List of recommended cleaning agents, tools, and maintenance supplies.

Instructions for cleaning machine parts like the engraving table, windows, and enclosure.

How to clean lenses and mirrors, and a suggested schedule for system maintenance.

Steps to re-align the machine's focus system after potential issues or handling.

Detailed procedure for manually adjusting the Z-axis and setting the focus using a wedge.

Explanation of the 'Tickle' parameter and when its adjustment might be necessary.

Step-by-step guide to adjust the Tickle parameter using a test file and specific keys.

Details on machine dimensions, weight, packaging, and engraving area sizes.

Engraving speeds, repeatability, sound levels, and operating temperature/humidity.

Information on lenses, LASER source type, wavelength, and beam diameter.

Power requirements, insulation, electromagnetic compatibility, and connection types.

Details on firmware, driver compatibility, and available optional accessories.

Specifications for cylinder attachment, slant stand, cutting kit, and honeycomb table.

| Brand | GRAVOGRAPH |

|---|---|

| Model | L-Solution 700 |

| Category | Printer |

| Language | English |

Loading...

Loading...