G0513 Series Bandsaws (Mfd. Since 07/18)

-23-

Using Wood Blocks

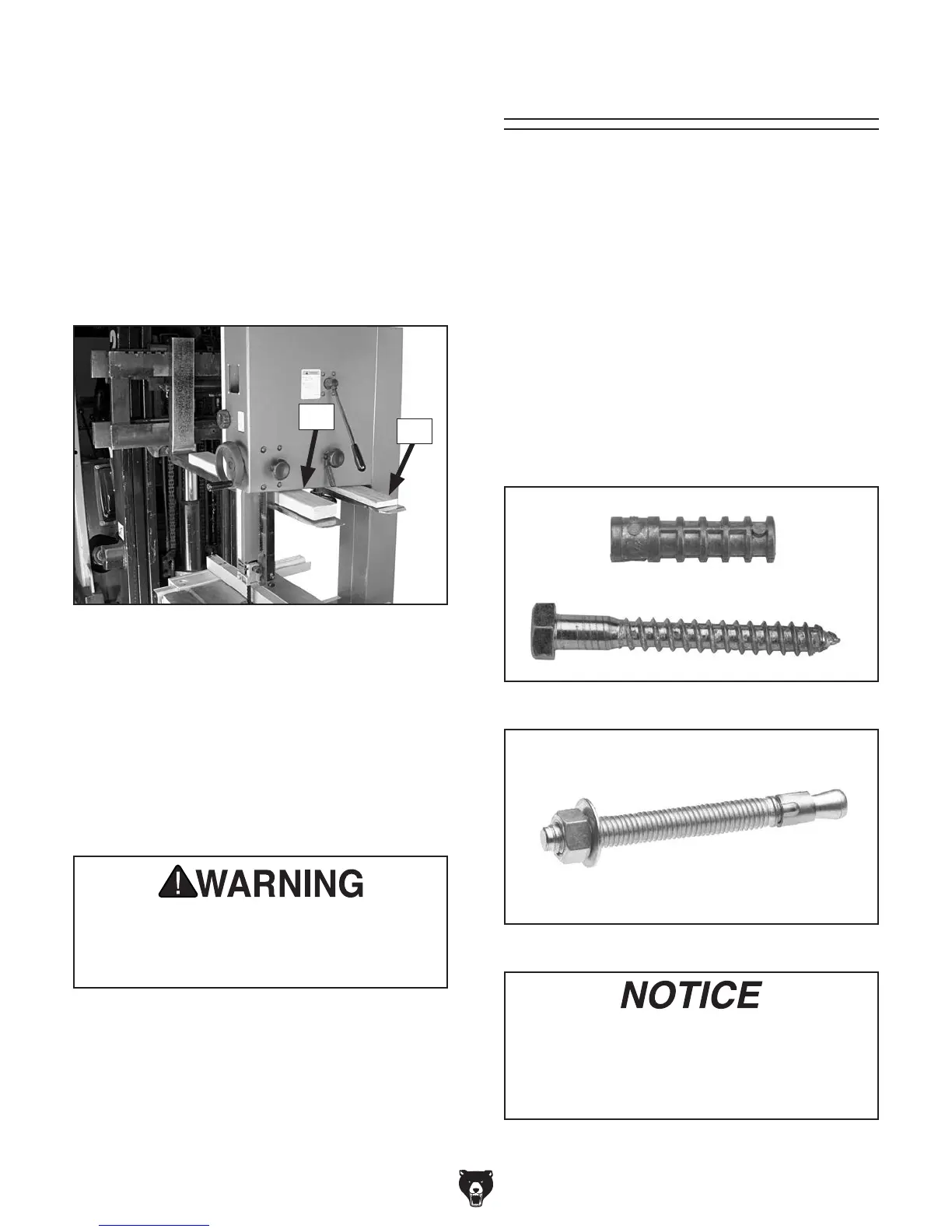

1. Move the crate to the prepared location, then

remove the crate from the shipping pallet.

2. Unbolt the bandsaw from the pallet.

3. Carefully place the forklift forks under the

head and insert a 1x4 block between the head

and the left fork and a 2x4 block between the

head and right fork so the bandsaw is level,

as shown in Figure 18.

4. Lift the bandsaw off of the pallet, remove the

pallet, then slowly set the bandsaw into posi-

tion.

Note: If you are concerned about your forklift

forks hitting the tension handwheel, remove the

handwheel before positioning the forks, then rein-

stall it after placing.

Figure 18. Example photo of lifting bandsaw with

forklift using wood shims.

2x4

1x4

Serious injury could occur if you connect

machine to power before completing setup

process. DO NOT connect to power until

instructed later in this manual.

We recommend mounting your new machine to

the floor. Because floor materials may vary, floor

mounting hardware is not included. You may also

mount your machine to a mobile base that has

wheel locking or wheel retracting capabilities that

keeps the mobile base from rolling when not in

use.

Bolting to Concrete Floors

Lag shield anchors with lag bolts (see Figure 19)

and anchor studs (see Figure 20) are two popular

methods for anchoring an object to a concrete

floor. We suggest you research the many options

and methods for mounting your machine and

choose the best that fits your specific application.

Mounting

Figure 19. Typical lag shield anchor and bolt.

Figure 20. Typical anchor stud.

Anchor studs are stronger and more per-

manent alternatives to lag shield anchors;

however, they will stick out of the floor,

which may cause a tripping hazard if you

decide to move your machine.

Loading...

Loading...