G0513 Series Bandsaws (Mfd. Since 07/18)

-61-

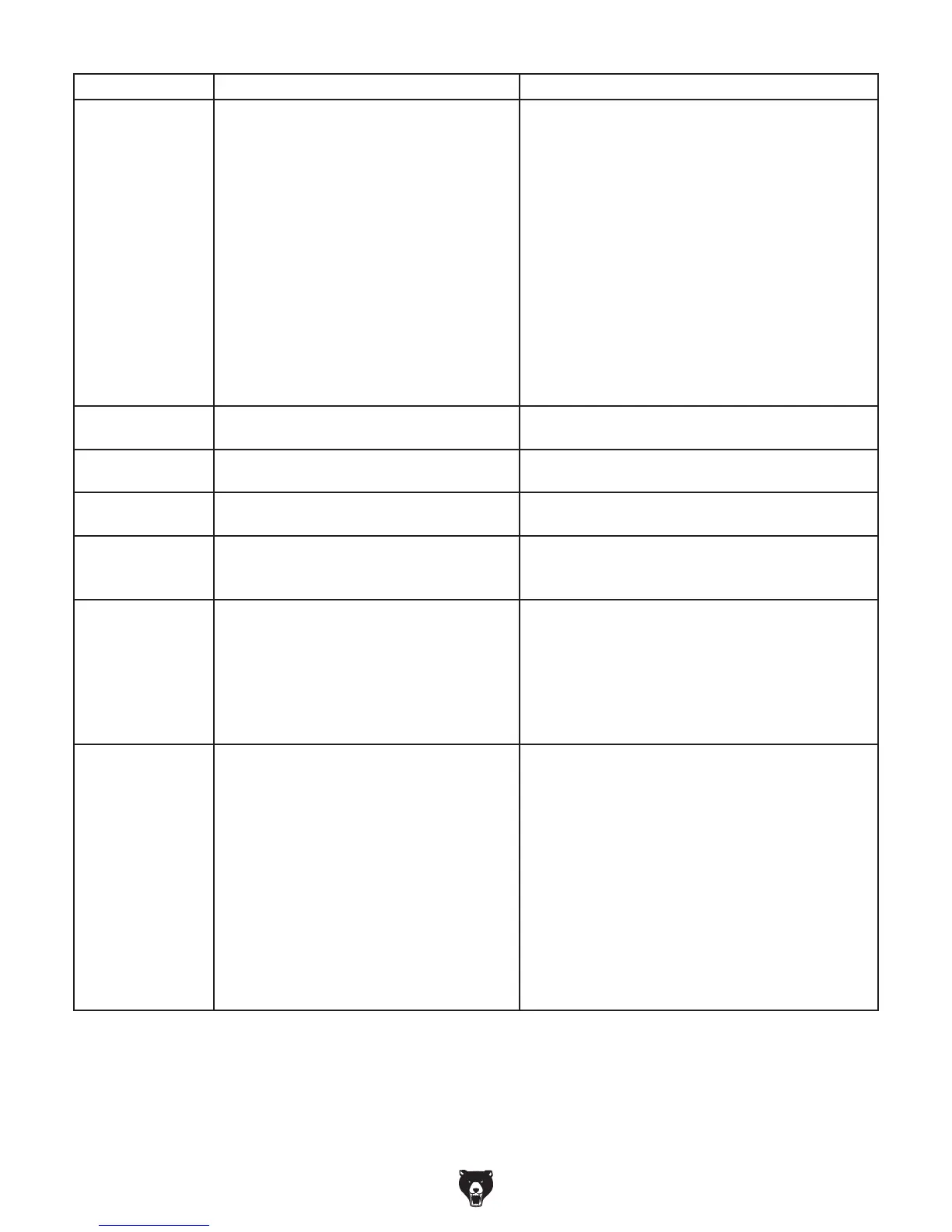

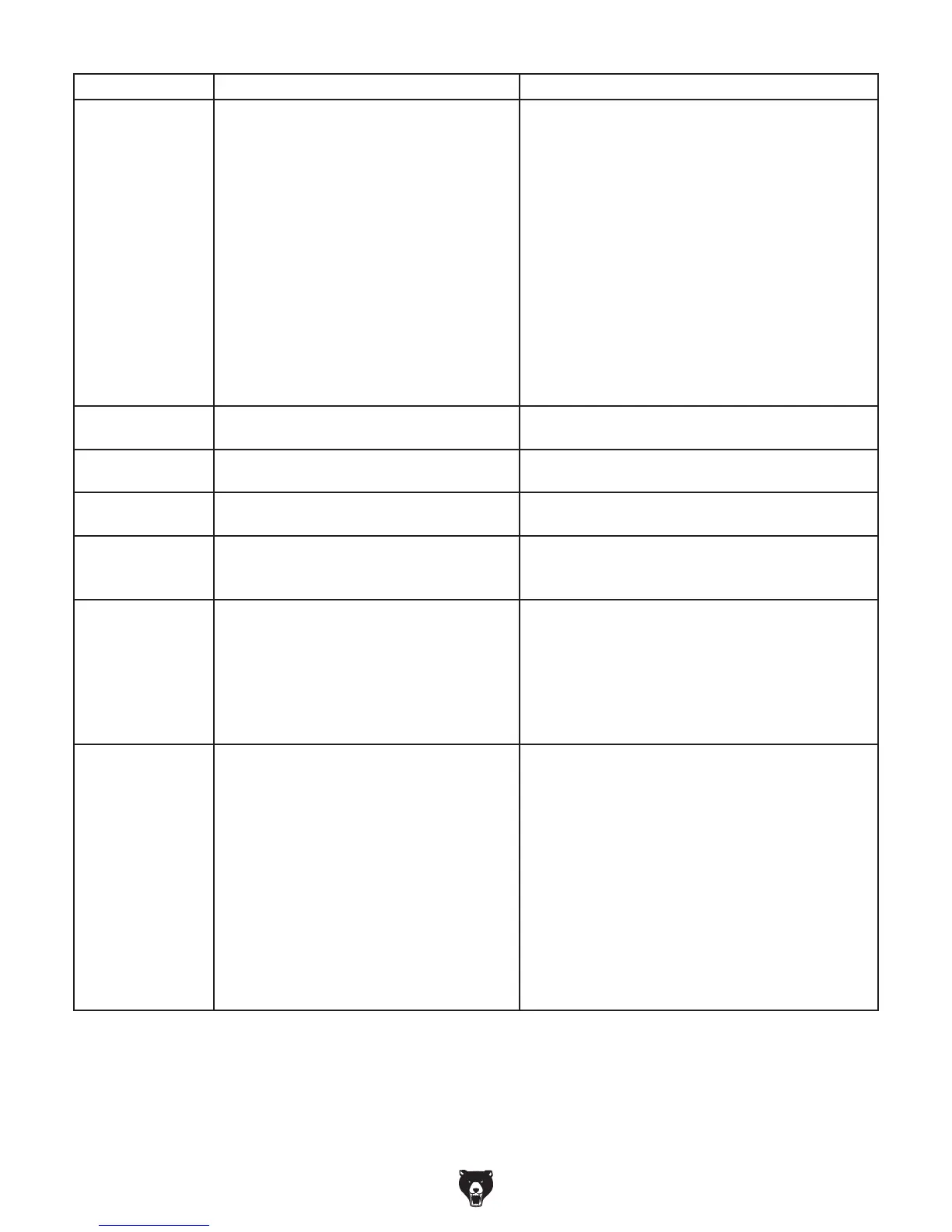

Symptom Possible Cause Possible Solution

Machine stalls

or slows when

operating.

1. Too much pressure against workpiece.

2. Workpiece too moist or unsuitable.

3. Workpiece is warped.

4. Fence incorrectly adjusted.

5. V-belt slipping.

6. Run capacitor at fault.

7. Motor connection wired incorrectly.

8. Motor overheated.

9. Contactor has poor contacts or is at fault.

10. Centrifugal switch at fault.

11. Motor at fault.

1. Decrease the feed rate or workpiece pressure.

2. Only cut wood and ensure moisture is below 20%.

3. Straighten workpiece or use a different one.

4. Adjust/calibrate fence (Page 40).

5. Tension/replace V-belt (Page 63); ensure pulleys

are aligned.

6. Test/repair/replace.

7. Wire motor correctly. Refer to diagram inside junction

box or the wiring diagrams beginning on Page 71.

8. Let cool, clean motor, and reduce workload.

9. Test all legs for power, test field coil, and fix contacts

or replace if at fault.

10. Adjust/replace centrifugal switch if available.

11. Test for shorted windings, bad bearings and repair

or replace.

Miter bar binds in

miter slot.

1. Miter slot dirty or gummed up. 1. Carefully clean miter slot.

Table does not tilt

to 0 degrees.

1. Pointer or scale calibrated incorrectly.

2. Positive stop bolt not set correctly.

1. Calibrate pointer/scale at true 0 degrees.

2. Adjust positive stop bolt (Page 29).

Table does not tilt

to 45 degrees.

1. Pointer or scale calibrated incorrectly.

2. Machine component blocking path.

1. Calibrate pointer/scale at true 45 degrees.

2. Remove component blocking table.

Table hard to tilt. 1. Sawdust or pitch trapped between trunnion

and base.

2. Metal burrs on trunnion.

1. Clean/lubricate sliding surfaces of trunnions

(Page 59).

2. Remove burrs.

Cuts are rough or

show scoring.

1. Blade is overloaded and twists.

2. Blade TPI is too coarse or speed incorrect.

3. Blade is loose and slipping on wheels.

4. Blade tracking is incorrect.

5. Blade has missing or bent teeth.

6. Blade has a faulty weld.

1. Decrease the feed rate or workpiece pressure.

2. Use correct blade for application (Page 47).

3. Re-tension blade (Page 33).

4. Adjust blade tracking (Page 28) or adjust wheels

coplaner (Page 68).

5. Replace the blade (Page 51).

6. Replace the blade (Page 51).

Blade or teeth

break.

1. Blade tension too high.

2. Incorrect blade for application.

3. Feed rate or blade speed is too fast.

4. Operator is cutting corners too sharply.

5. Blade is dull.

6. Blade tracking is wrong.

7. Blade guides adjusted incorrectly.

8. Inadequate blade support near cutting

area.

9. Blade weld at fault.

10. Wheel tires worn or damaged.

11. Fence or miter slot not aligned with blade.

1. Decrease blade tension (Page 33).

2. Use correct blade for application (Page 47).

3. Reduce feed rate or increase blade speed.

4. Use a wider arc on outside cuts, or use relief cuts to

make tight inside cuts.

5. Replace blade (Page 51).

6. Adjust blade tracking (Page 46).

7. Re-adjust blade guides (Page 36).

8. Adjust upper blade guide closer to workpiece

(Page 36).

9. Replace blade (Page 51).

10. Replace tires.

11. Align miter slot and fence with blade (Page 39).

Loading...

Loading...