English (GB)

12

4.4.3 Dosing control (Flow Monitor)

The pressure sensor (Flow Monitor pump option) is used as a

dosing controller and to monitor the pressure for the whole power

ranges.

The Flow Monitor for dosing control consists of a pressure sensor

integrated in the dosing head.

The pressure sensor is available as Flow Monitor pump option.

The pressure sensor is fitted to the pump on delivery. Upgrades

are not possible.

4.4.4 Flow compensation

The flow compensation is a function to keep the dosing flow

constant with changing system pressure. Pressure changes are

detected by the pressure sensor and the motor speed is adjusted

accordingly.

To use this function, pressure control or dosing control (Flow

Monitor) has to be activated in the electronics.

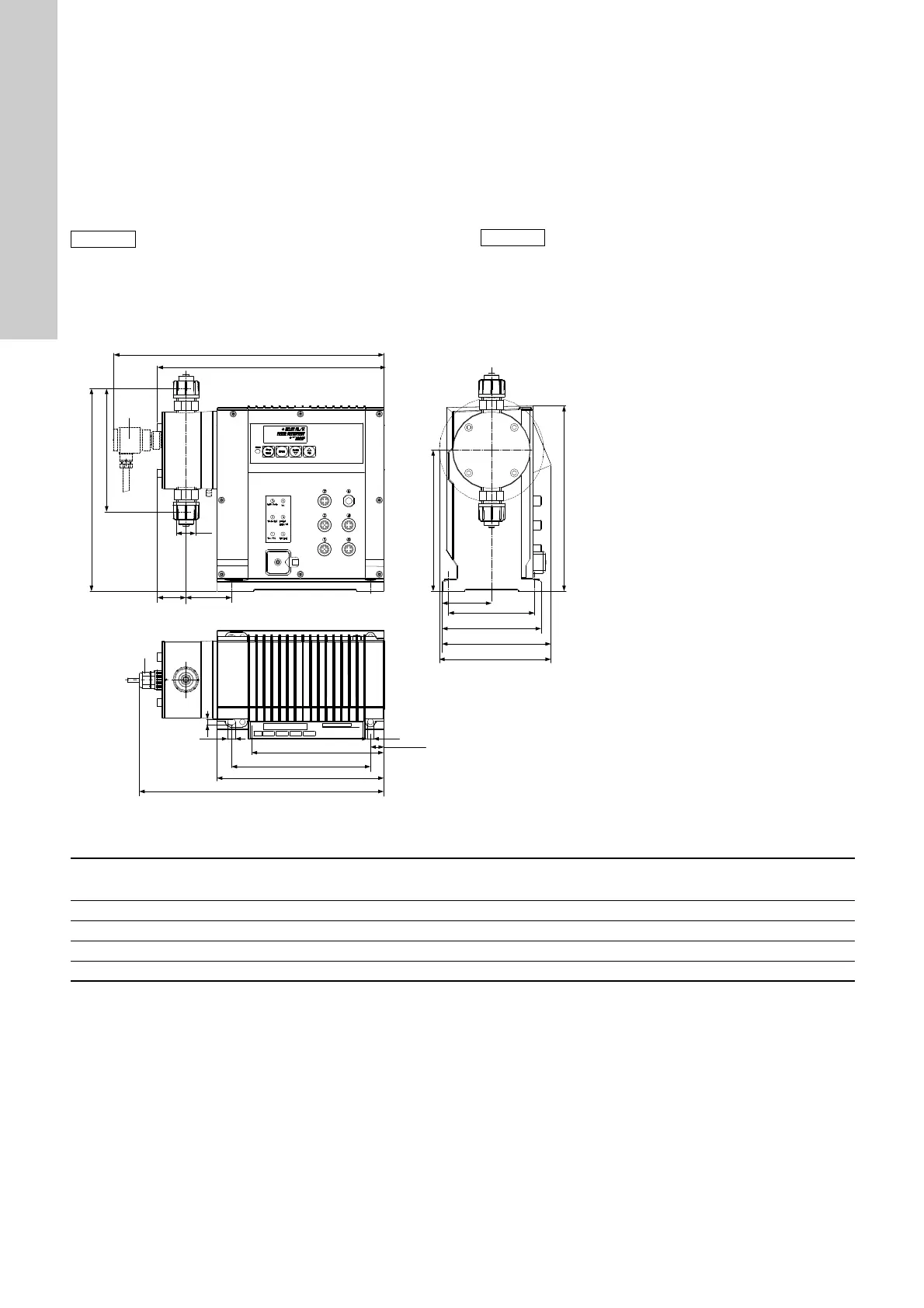

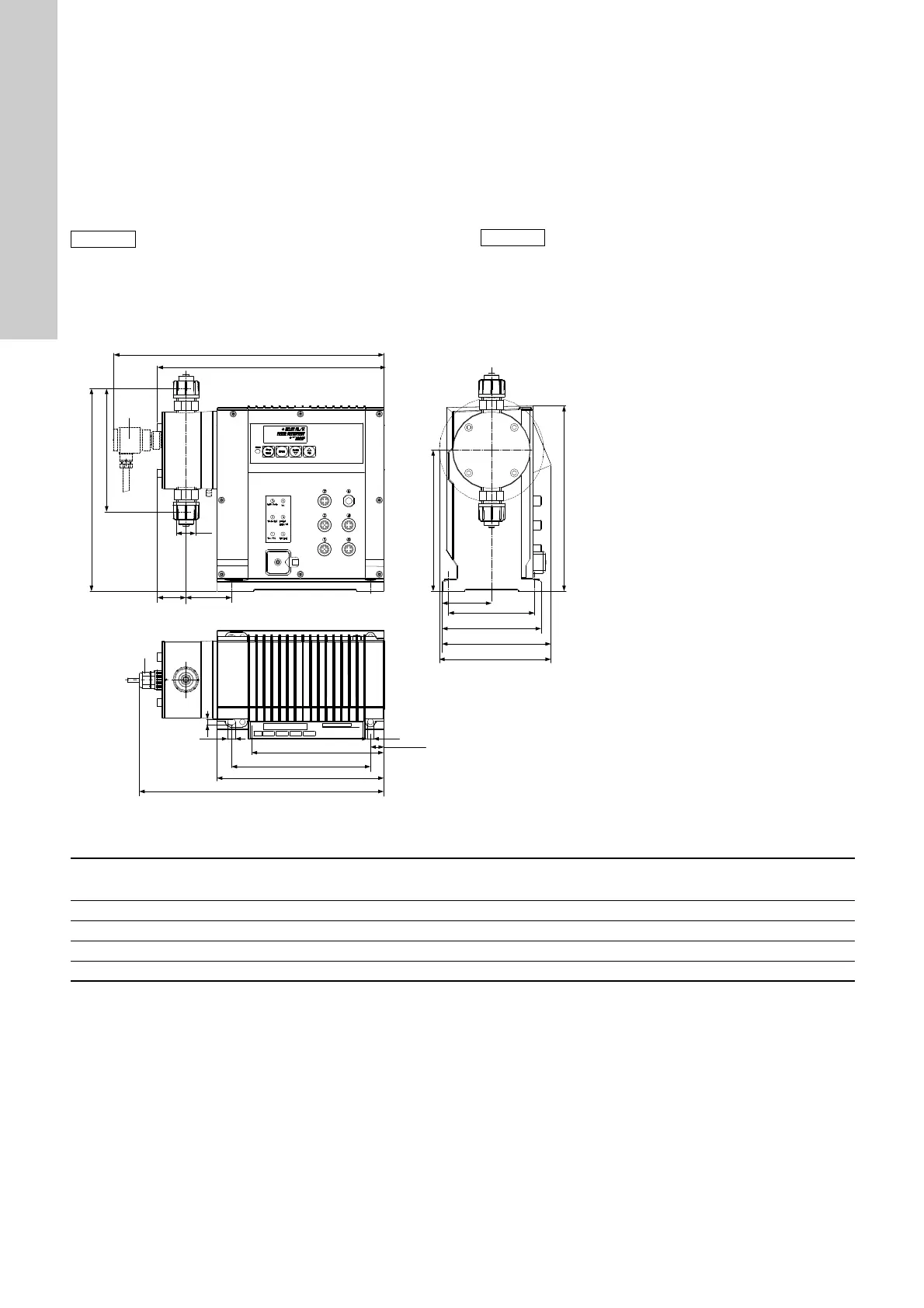

4.5 Dimensional sketches

Fig. 4 DDI 222

Dimensions for DDI 222

Pressure control is primarily used to protect the

pump. This function is not a substitute for the

overflow valve.

When dosing media with a viscosity similar to water,

the pump needs not to be calibrated, as the pump

already responds to the possible change of the

system pressure.

When dosing media with a viscosity different from

water or after a software update, the pump has to be

calibrated.

TM03 6663 4506

A4

A3

H2

D1

C4

C1

207

172.5

16.5

Ø7

10

7

61.5

105

123

B3

B4

230

175

(159)

A5

H3

MLS

DS

MBS: Diaphragm leakage sensor (optional)

DS: Pressure sensor (Flow Monitor pump option)

A3

[mm]

A4

[mm]

A5

[mm]

B3

[mm]

B4

[mm]

C1

[mm]

C4

[mm]

D1

H2

[mm]

H3

[mm]

DDI 60-10 283 338 306 137 - 58 37 R 5/8 252 153

DDI 150-4 315 372 350 137 139 90 39 R 1 1/4 265 179

DDI 60-10 / HV 295 350 328 137 - 68 38 R 1 1/4 246 143

DDI 150-4 / HV 315 372 350 137 139 90 39 R 1 1/4 265 179

Loading...

Loading...