English (GB)

15

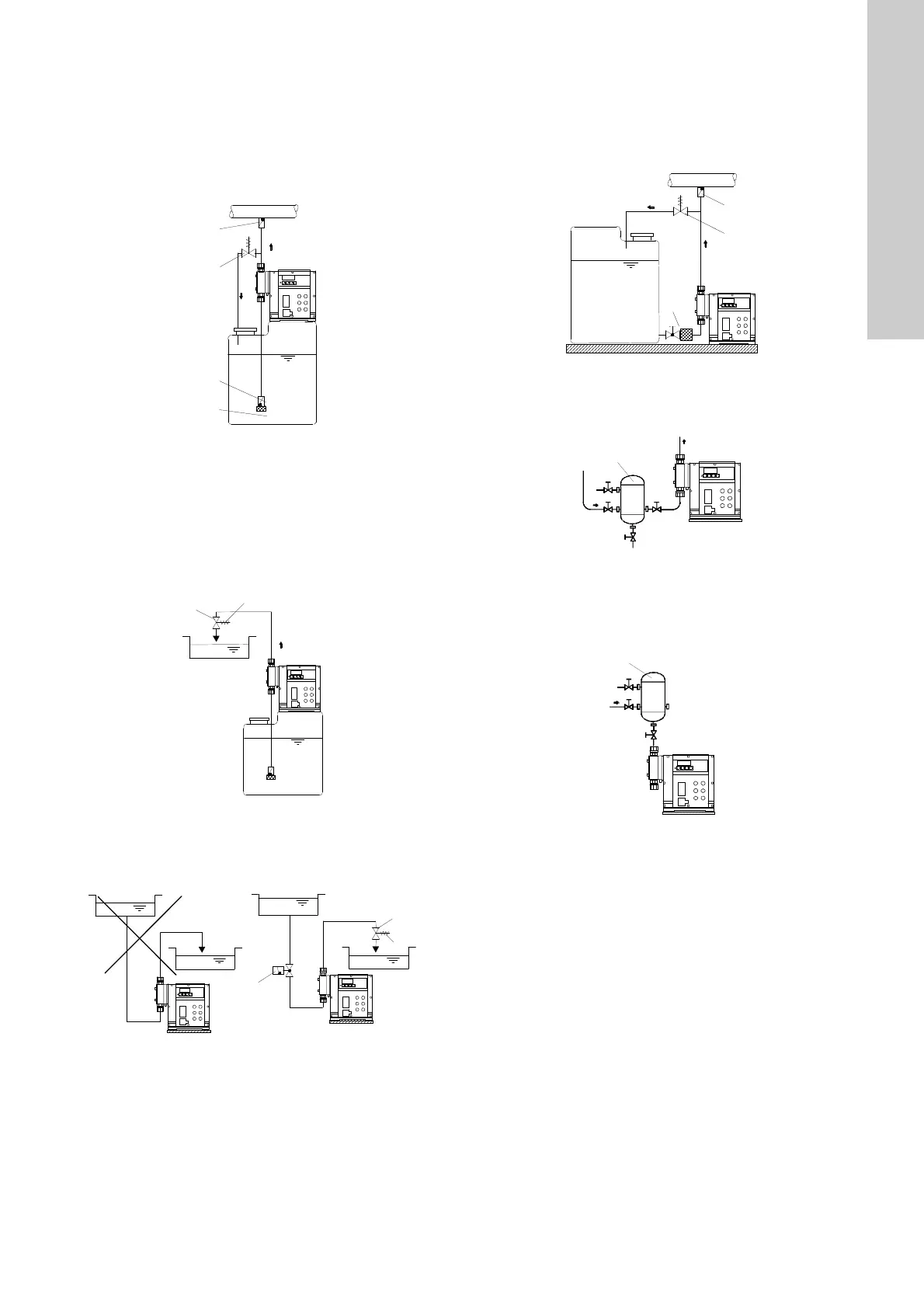

5.4.1 Installation tips

• For non-degassing media with a viscosity similar to water, the

pump can be mounted on the tank (observe the permissible

suction lift).

• Flooded suction preferred.

• For media with a tendency to sedimentation, install the suction

line with filter (15i) so that the suction valve remains a few

millimetres above the possible level of sedimentation.

Fig. 7 Tank installation

With open outflow of the dosing medium or low

counter-pressure

A positive pressure difference of at least 1 bar must be ensured

between the counter-pressure at the injection point and the

pressure of the dosing medium at the pump suction valve.

• If this cannot be ensured, install a pressure-loading valve (7i)

immediately before the outlet or the injection unit.

Fig. 8 Installation with pressure-loading valve

• To avoid the siphon effect, install a pressure-loading valve (7i)

in the discharge line and, if necessary, a solenoid valve (14i) in

the suction line.

Fig. 9 Installation to avoid the siphon effect

• To protect the dosing pump against excessive pressure

build-up, install a relief valve (6i) in the discharge line.

• For degassing media:

– Flooded suction.

– Install a filter (15i) in the suction line to prevent the valves

being contaminated.

Fig. 10 Installation with relief valve and filter

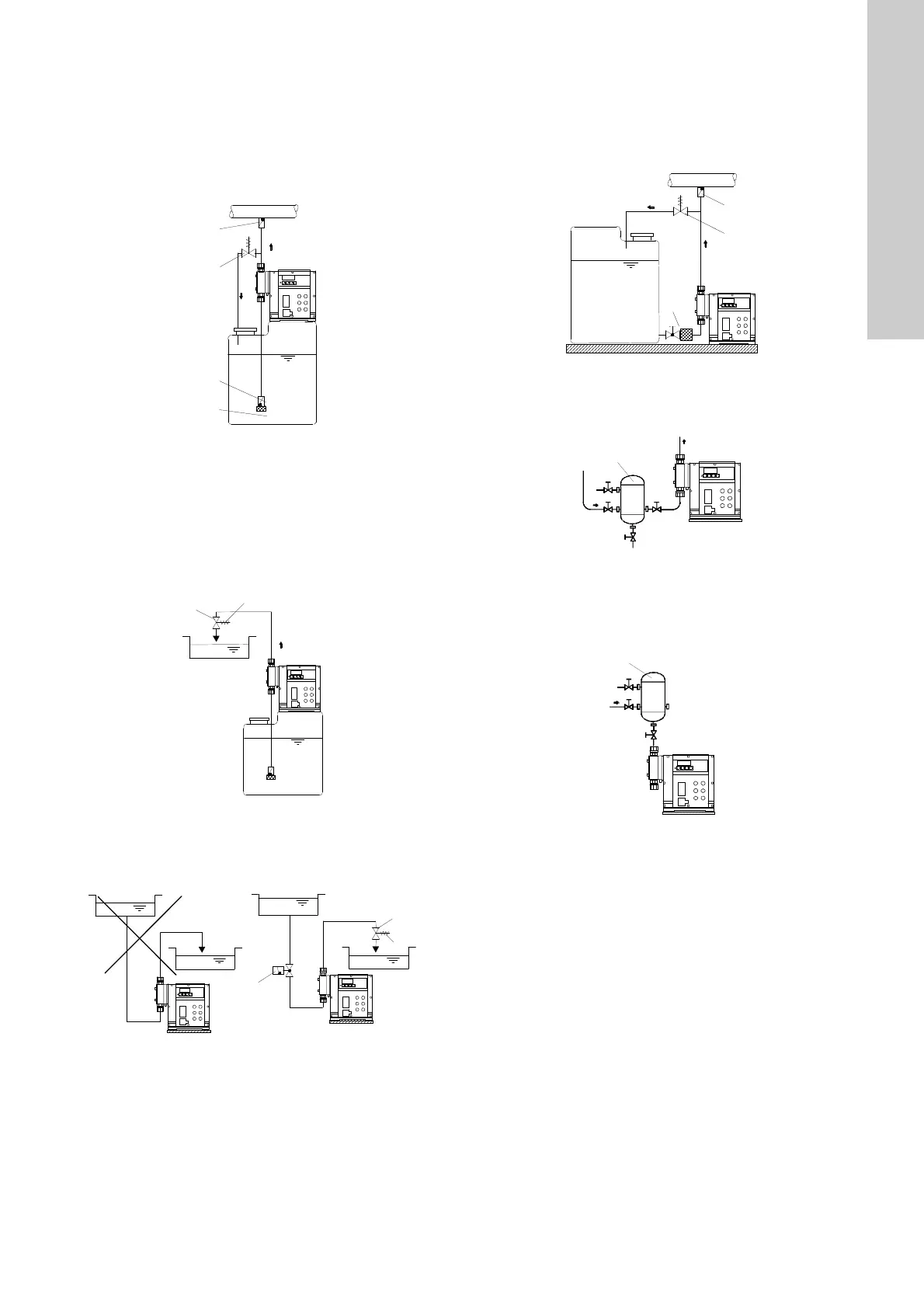

• For line lengths above 1 metre a suction pulsation damper (4i)

may be required, depending on the flow rate.

Fig. 11 Installation with suction pulsation damper

• For damper and line lengths above 3 metres and for flexible

pipework and line lengths above 5 metres, a pulsation damper

(8i) must be used to protect the system.

Fig. 12 Installation with pulsation damper

TM03 6666 4506TM03 6667 4506TM03 6668 4506

TM03 6669 4506TM03 6670 4506TM03 6671 4506

Loading...

Loading...