39

Section 6 Maintenance and Troubleshooting

6.1 Maintenance

6.1.1 Maintenance schedule

This following table shows the recommended maintenance schedule for the ORBISPHERE

3100 instrument. This proposed schedule should be modified according to operating conditions.

6.1.2 Instrument batteries

The instrument is designed to operate on rechargeable batteries. When battery power becomes

low, the batteries can be recharged by connecting the instrument to the mains power supply

using the supplied power adapter and cable. When connected, the batteries are automatically

recharged.

6.1.3 Oxygen sensor

WARNING

If the instrument is being powered by mains power, disconnect the instrument from the

power supply before carrying out this procedure.

Based on instrument usage of 8 hours/day and 365 days/year, the sensor spot will need to be

replaced about once every 4 years. The procedure is very simple and takes no more than a few

minutes.

Before starting, ensure you have the replacement flow chamber assembly as supplied with the

maintenance kit (part number

DG33228). Switch the instrument OFF and make sure it is

disconnected from any mains power supply.

Follow these instructions:

Interval Item

Daily

Clean outside of the instrument with a damp cloth and run clean water

through the instrument to clean the internal passageways

Weekly

Clean outside of the instrument with a damp cloth and run 20 mL of ethanol

(EtOH) through the instrument to clean the internal passageways

Monthly

Run warm water through the instrument followed by 20 mL of ethanol (EtOH).

Dry by flowing dry air or N

2

through the instrument

Yearly Calibrate the oxygen sensor

Every 4 years Replace the oxygen sensor spot and perform a sensor calibration

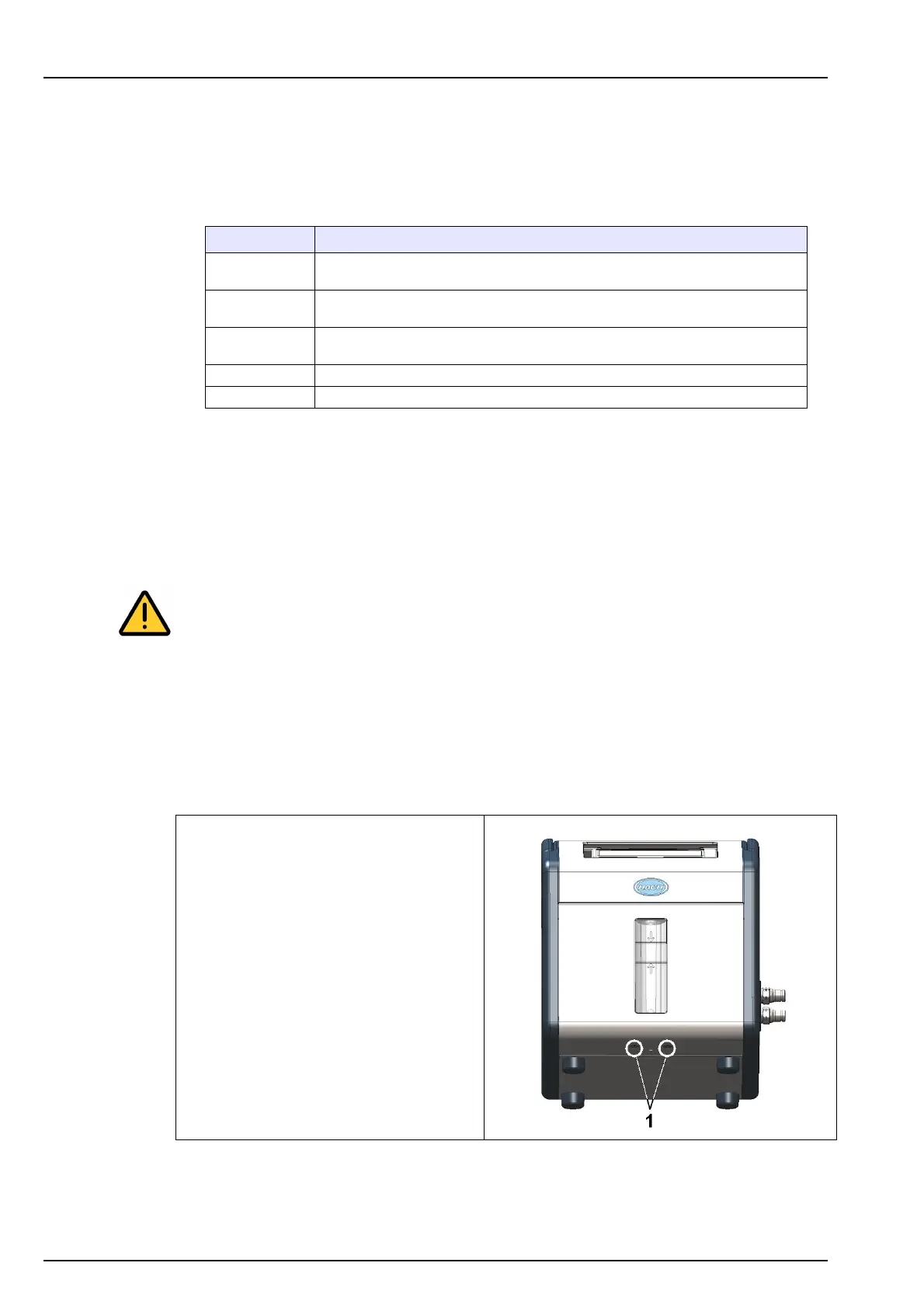

1. Remove the front panel from the

instrument by unscrewing the 2 screws

underneath the instrument (No. 1) that

secure it in place.

Use the cross screwdriver supplied in

the tool kit for this purpose.

Loading...

Loading...