Wheel Alignment AXIS500

AXIS500 Manual Instructions

Adjustment by Run-out compensation

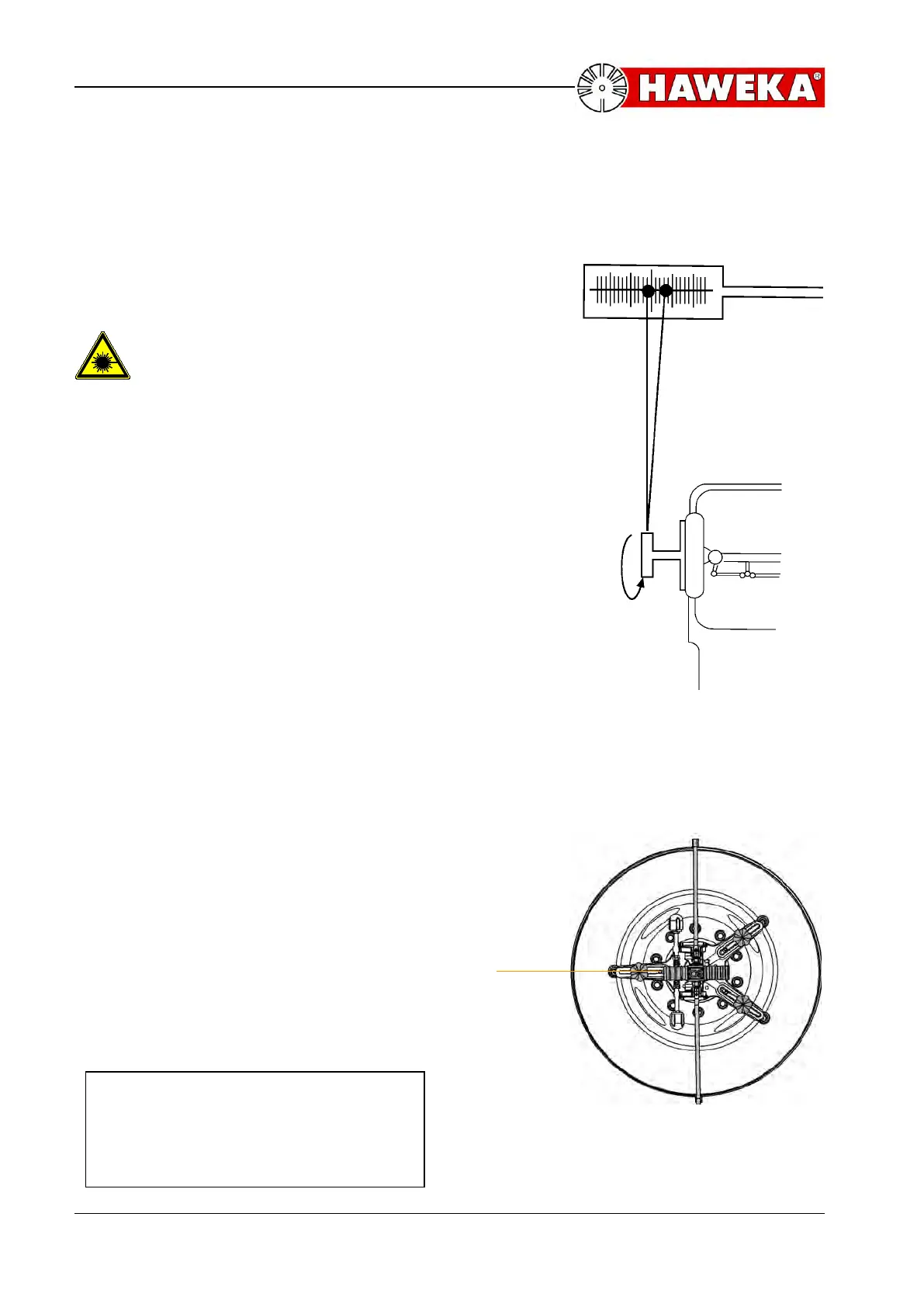

Runout adjustment of the laser head:

A toe scale is put in front of the vehicle at a

distance of three meters. Switch the laser on.

Pay attention to laser beam output

opening before switch on!!

The laser point is directed towards the scale

and the latter is set at zero. The rim is turned by

360° while the laser beam points at the scale.

Example: while turning, the point on the scale

travels to the right side of „0“, the fourth scale

line being the maximum value, and to the left

side of „0“, the second scale line being the other

maximum value, resulting in the point’s

travelling over a path of six scale units

A maximum value is set by turning the wheel

again. Memorize from which direction - left or

right - the point approaches the set maximum.

This value is fixed again by shifting the toe

scale to „0“. Afterwards a new value, i.e. half

the distance the point moved during the

revolution, is set on the scale by adjusting the

measuring adaptor. This is done with each

adapter by turning the knurled rings. They have

to be turned to the opposite direction from

which the point approached its maximum. The

three adjusting feet are adjusted up to three

lines. Turn again and check whether the point

still moves on the scale. If this is the case, the

adjustment has to be repeated until the point

no longer moves on the scale when turning the

wheel.

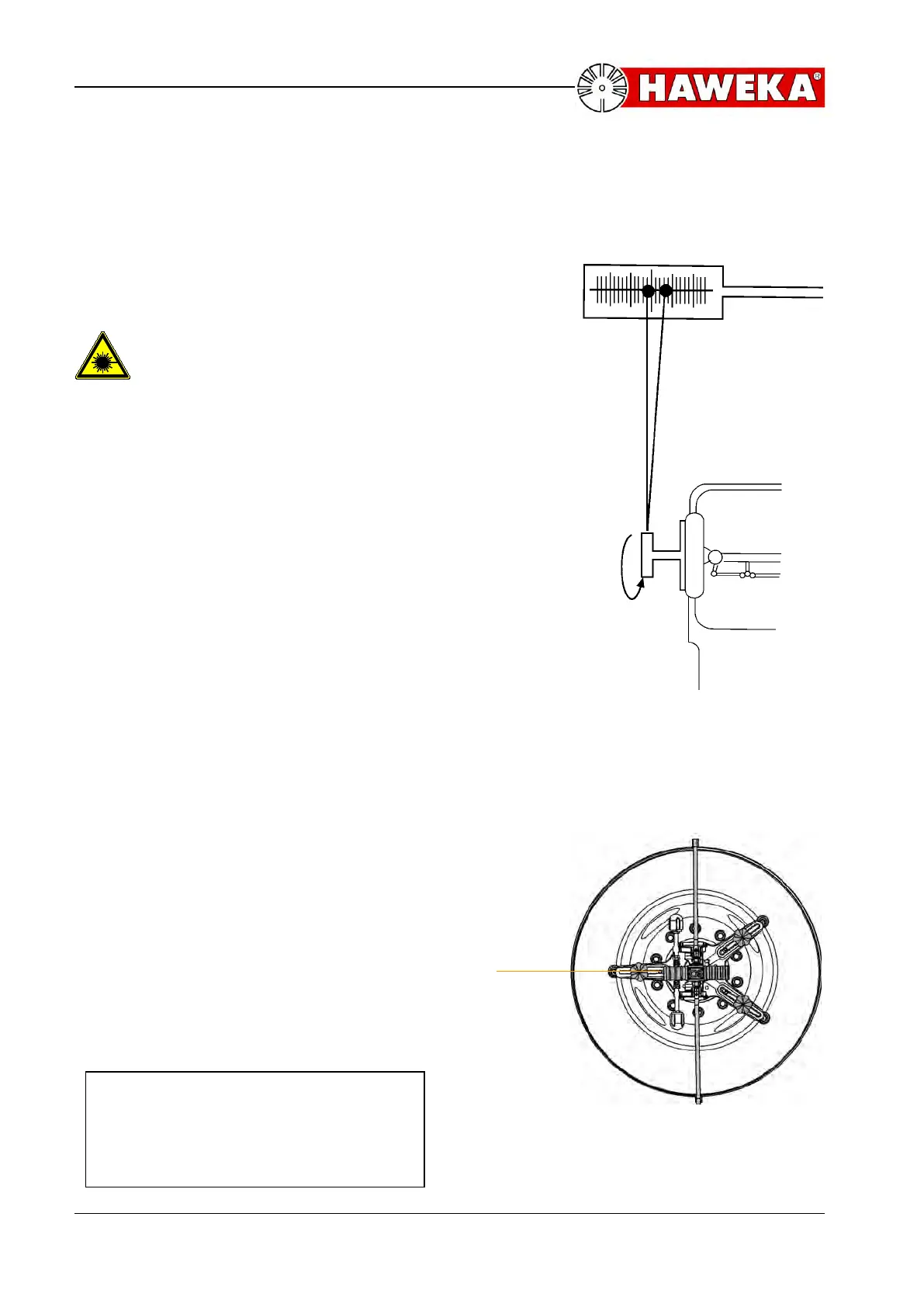

The position is always correctly adjusted, if one

adaptor is located in the same direction on the

layer beam.(Illustration 39)

Final Check:

The laser point must not move

laterally on the toe scale when

turning the wheel.

Loading...

Loading...