Wheel Alignment AXIS500

AXIS500 Manual Instructions

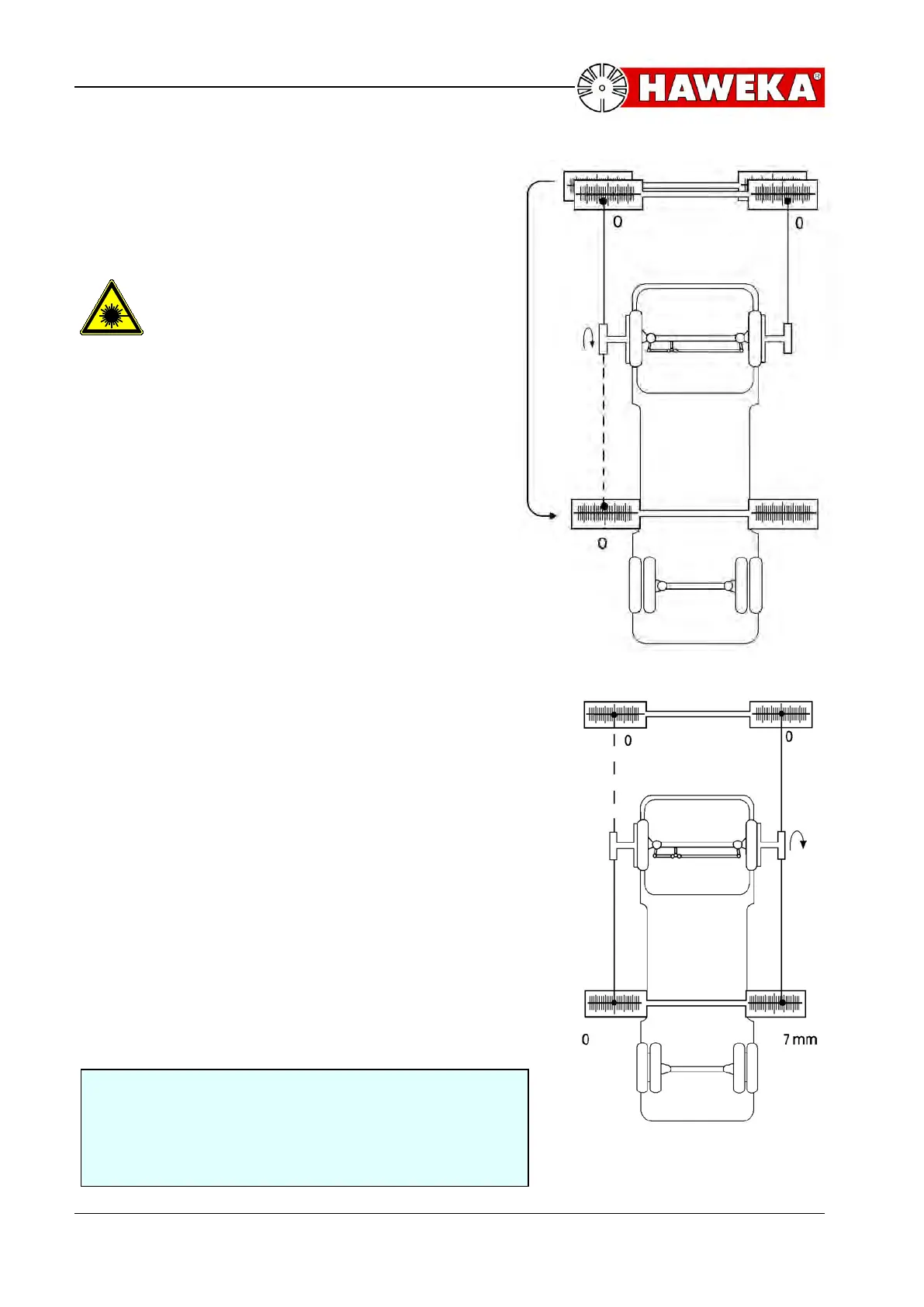

Front Wheel Alignment

Set-up of Toe Scales (continued)

• The toe scales are shifted on the chalk marking

in front of the front axle until both scales indicate

zero.

Turn the laser housing so that the laser

beam can travel above the floor.

• Fix the length of the toe scale by using the wing

screw and repeat procedure with the second toe

scale – both scales are now of identical length

(illustration 7).

• Now take one scale onto the marking behind the

front axle. – without changing the length.

• Turn the left-hand laser to the rear and shift the

total scale to zero.

Value rear left = 0

Value front left = 0

Value front right = 0

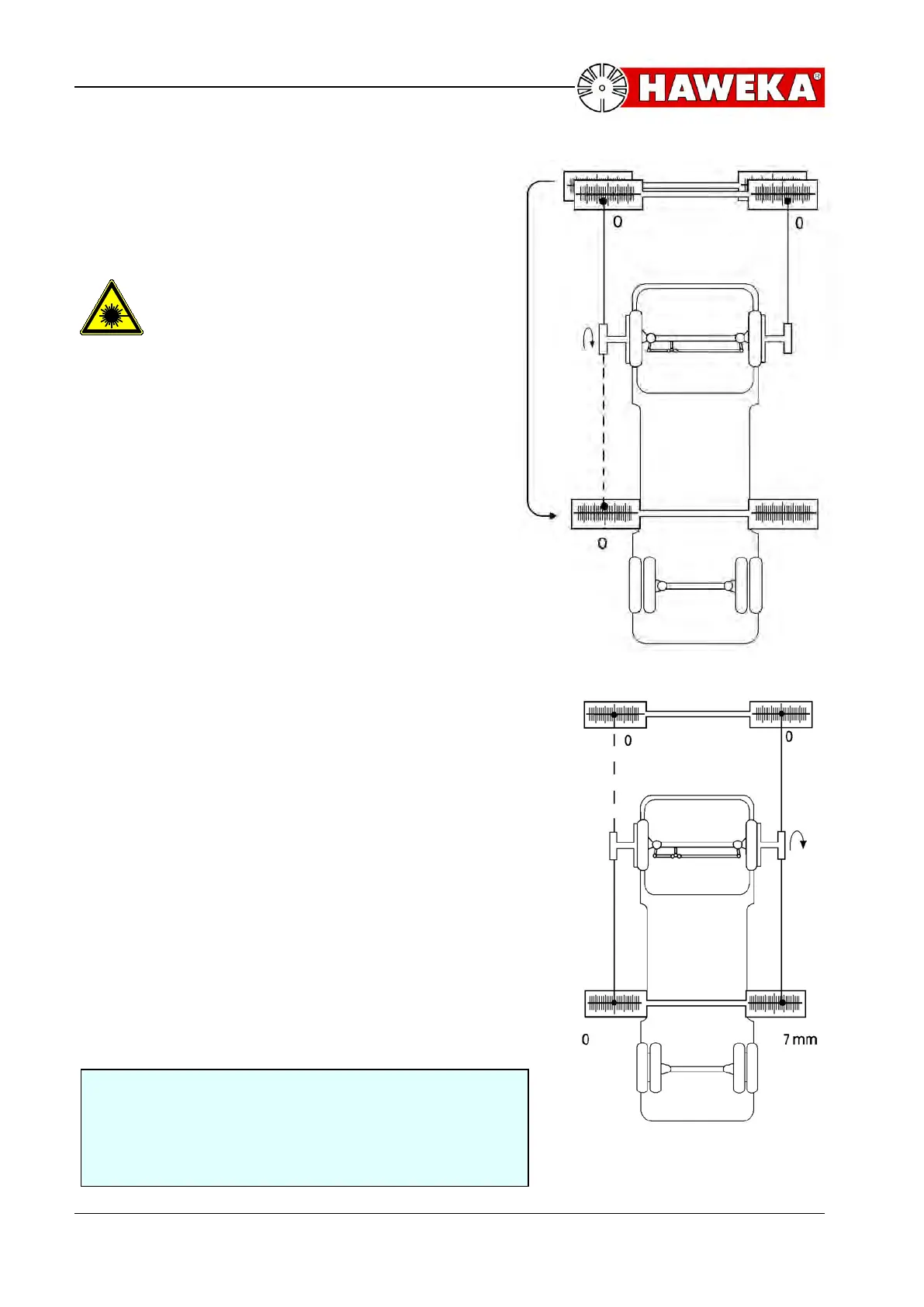

5.4 Toe Measurement and Alignment

Reading of Total Toe:

• Direct the right-hand laser to the rear onto the

toe scale.

• Read the measuring result:

1 long scale line

1,00 mm

1 half scale line

0.50 mm

1 quarter scale line

0.25 mm

The laser point points at zero = The toe is zero

The laser point points inward from zero= toe-out

The laser point points outward from zero= toe-in

• Proceed as follows, if the toe corresponds to the

specified values:

• Note measured value in the test record.

• Check „straight ahead position“ and steering

wheel center position

• look point 5.2 (Alignment of „Straight ahead

position“)

• If the toe does not correspond to the specified

values, toe alignment.

Example:

The laser point on the right-hand side behind the front

axle points at the 7th long outward scale line, i.e. the

front axle has a toe-in of 7 mm.(Illustration 8)

Loading...

Loading...