Preventive Maintenance

Chapter 6: General Procedures

Prima™ Procedural Light Service Manual (man247ra) Page 6 - 7

6

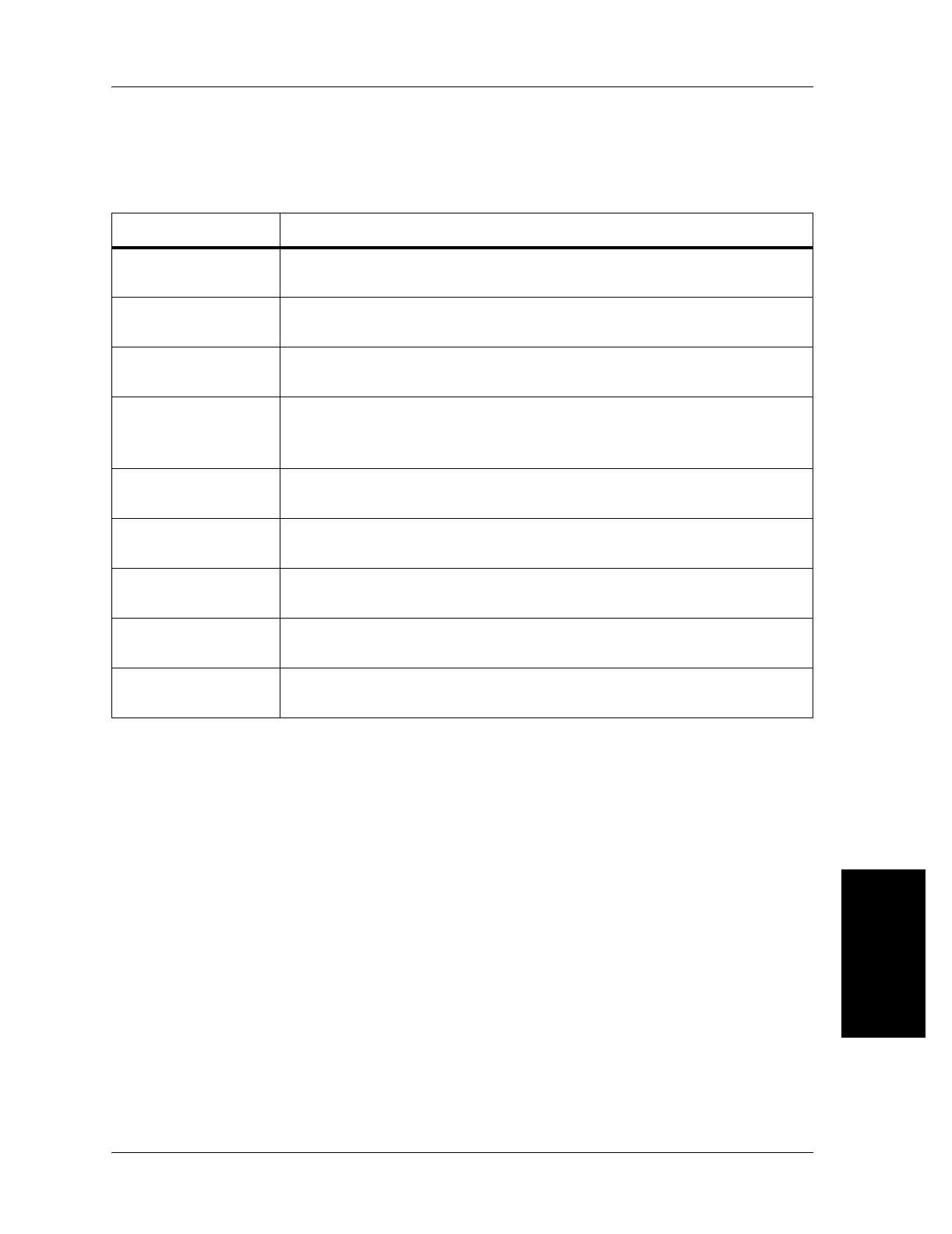

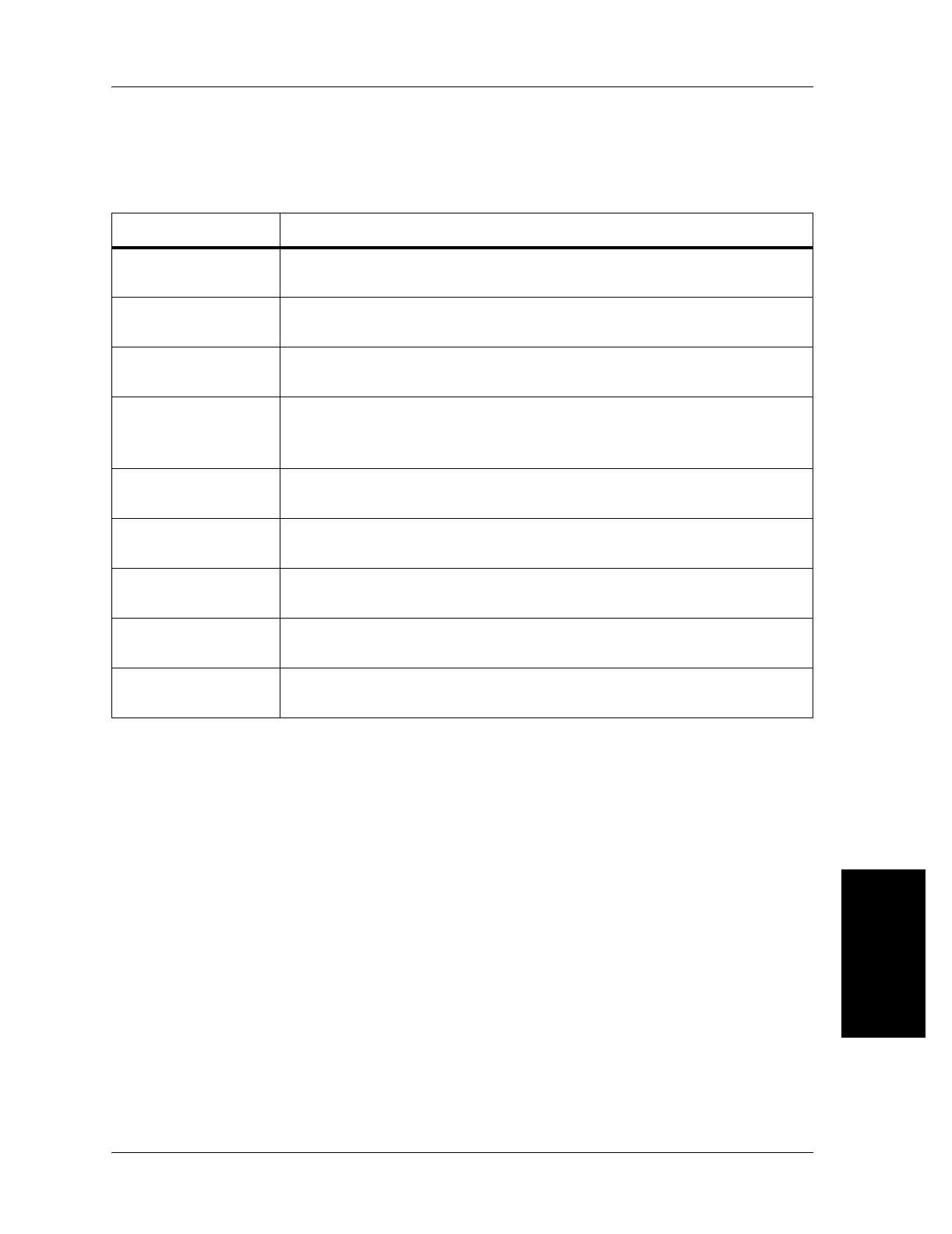

Preventive Maintenance Schedule

Table 6-1. Preventive Maintenance Schedule

Function Procedure

Lamp Ensure that the lamp is seated properly into the socket. See “Lamp”

on page 4-7.

Lamp head/yoke

assembly

Rotate and reposition the lamp head assembly. Verify that the assem-

bly moves freely and stays in position.

Lens Ensure the lens is mounted securely in the housing. Check the lens for

cracks or breaks, and replace if necessary. See “Lens” on page 4-10.

Rotating arm Move the rotating arm in all directions. Verify that the arm moves

freely and stays in position. Adjust the spring tension if the arm drifts

after positioning. See “Rotating Arm” on page 4-15.

Power cord Check for frayed power cord and components. Replace the damaged

parts if necessary. See “Power Cord” on page 4-20.

Performance Plug the unit into an appropriate power source. Turn the switch to the

on position. Check illumination of the lamp.

Electrical safety Check the unit for normal appearance and operation. Remove the unit

from service if it does not meet specifications.

Leakage Current

Test

With the ground wire open, the Prima™ Procedural Light must be

less than 65 microamperes to continue in service.

General appearance Check the cleanliness and aesthetics of the Prima™ Procedural Light.

See “Cleaning and Care” on page 6-3.

Loading...

Loading...