Service Manual iFLEX5

© Hirschmann Rev. I 0522/17 190154_I.DOC

6 LENGTH SENSING

The system measures the length of the main boom of the machine with a length sensor. The length

sensor is contained within the cable reel, located on the left side of the main boom.

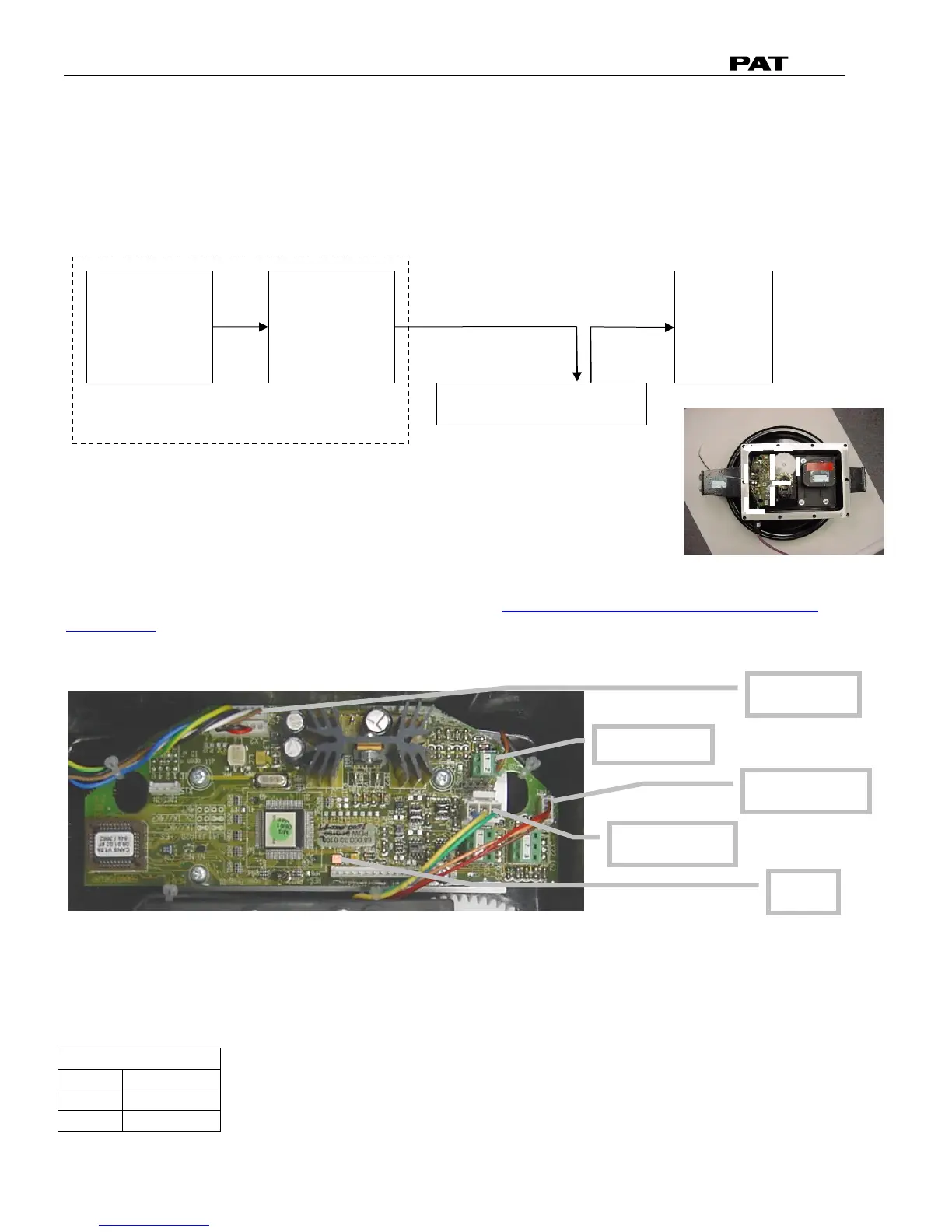

Block Diagram

The signal runs from the length sensor to the CAN-Bus converter board, both

located in the cable reel. From there, it travels as digital information on the

CAN-Bus to the pressure transducer, which acts as a T-connector to the main

CAN-Bus running to the central unit.

So, what do you do when you are having a problem with your length read-out?

Start by verifying the length display. Refer to the section “Troubleshooting A Sensor Problem Using

The Display” to call up the sensor signal on your console display. The CAN-Bus is digital and as such

will either transmit the signal correctly or not at all. If your readings are off, you have to determine

what is causing the problem (reference the following flow charts).

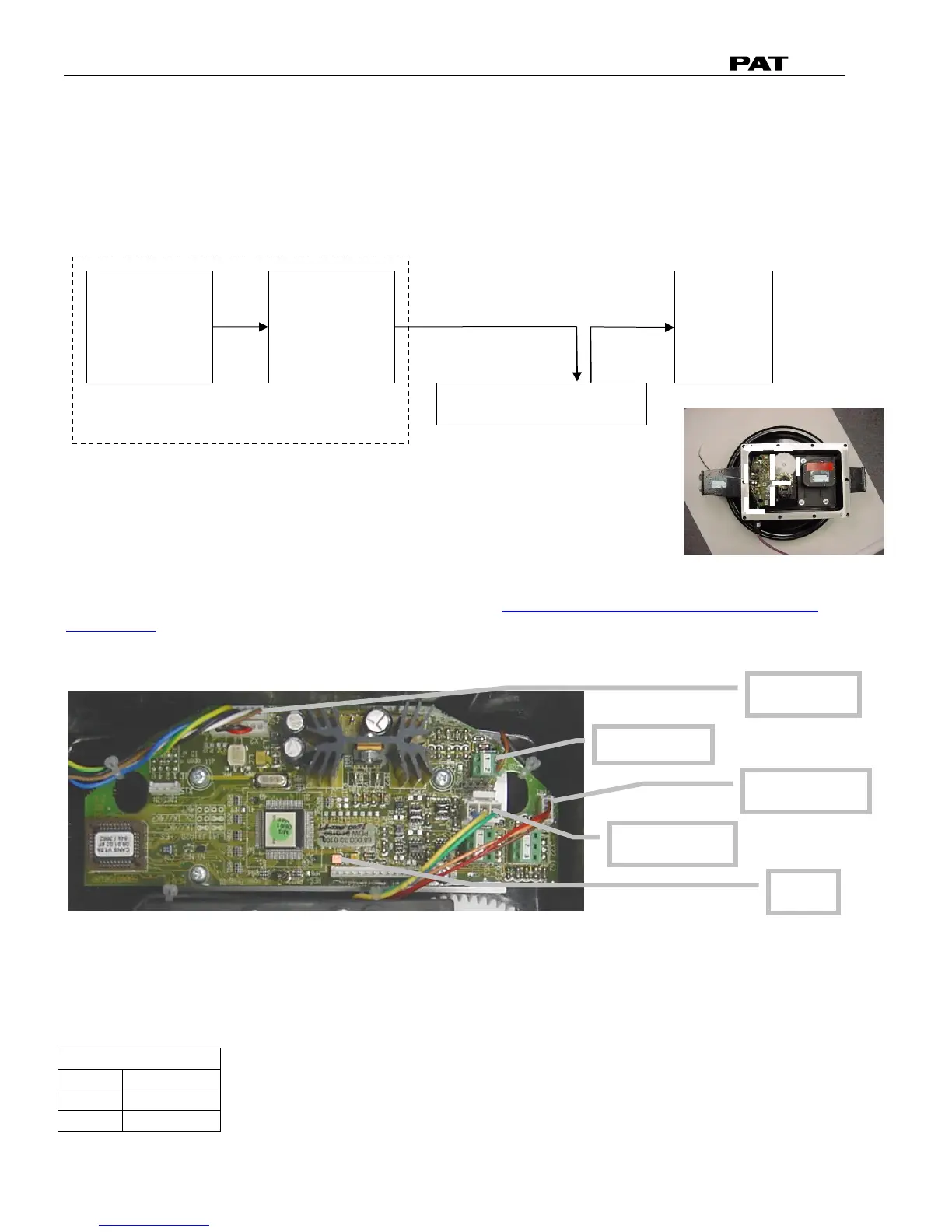

CAN-Bus electronics in cable reel.

The length sensor has a potentiometer built in that is driven by a gear drive from the cable drum. As

the length changes, the cable drum will turn and with it the potentiometer’s axle. The converter board

supplies a voltage of about 4.7V to the length potentiometer and in return monitors the output voltage

of the potentiometer. The terminal used is X20. The length sensor is connected as follows:

Loading...

Loading...