Service Screen For Sensor Calibration

© Hirschmann Rev. I 05/22/17 190154_I.DOC

17.2 ZERO-SETTING THE TRANSDUCER INPUTS

NOTE: The only thing adjustable for the pressure transducers is the zero point, which is the voltage

the transducer outputs when there is no (zero) pressure sensed.

CAUTION: Ensure there is no pressure in the hydraulic line when disconnecting the hoses from

pressure transducers.

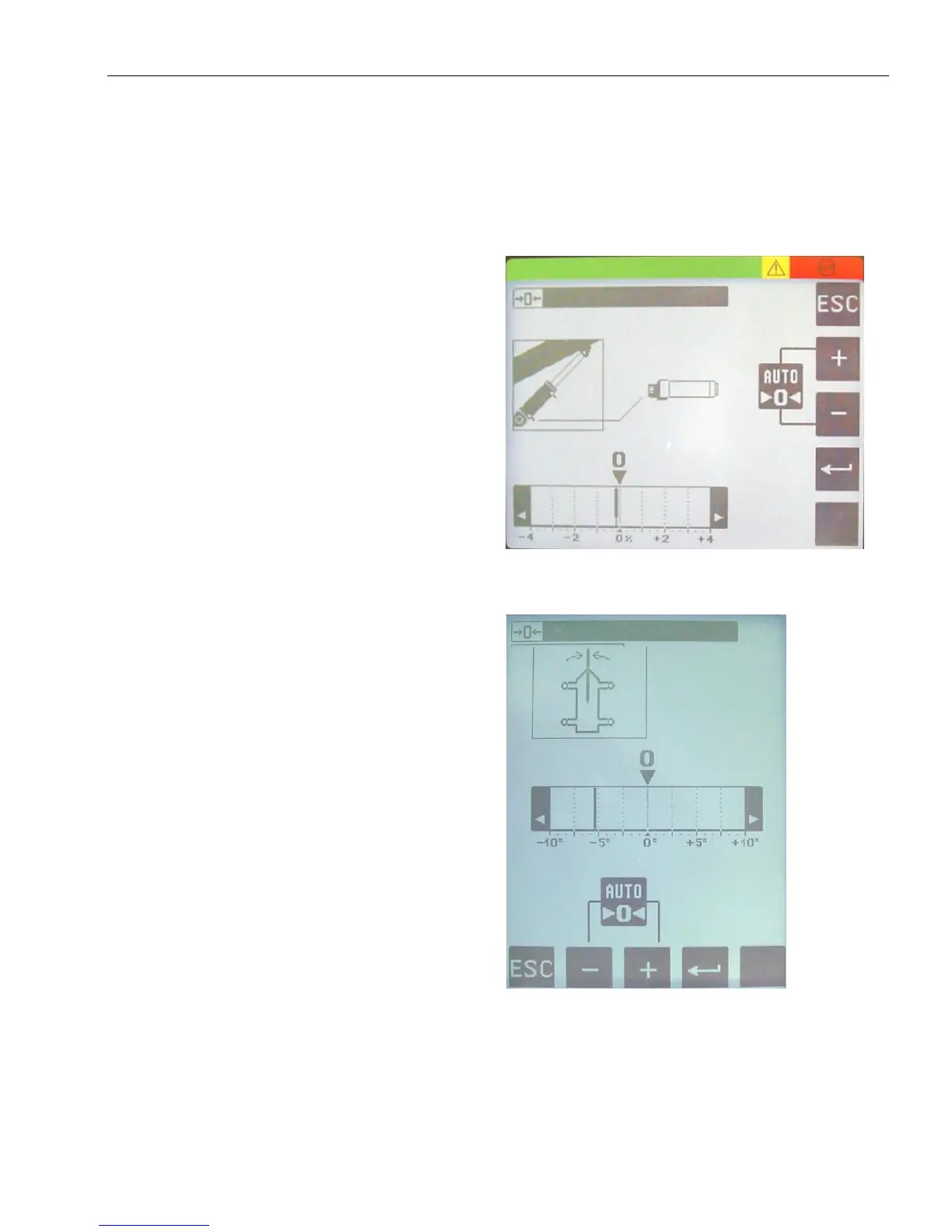

The display shows which transducer (piston-

side, rod-side or force) is being zeroed and a

horizontal dial marks the present pressure (or

force) difference in %. NOTE: there are 2

screens piston and rod transducers. By pressing

the + key, the input pressure (or force) is

adjusted upwards, and by pressing the minus (-)

key, the input value is adjusted downwards.

When the plus (+) and minus (-) keys are

pressed simultaneously, the zero setting occurs

automatically. Manual adjustments may be

preformed using + or -.

17.3 ZERO-SETTING THE SLEWING INPUTS

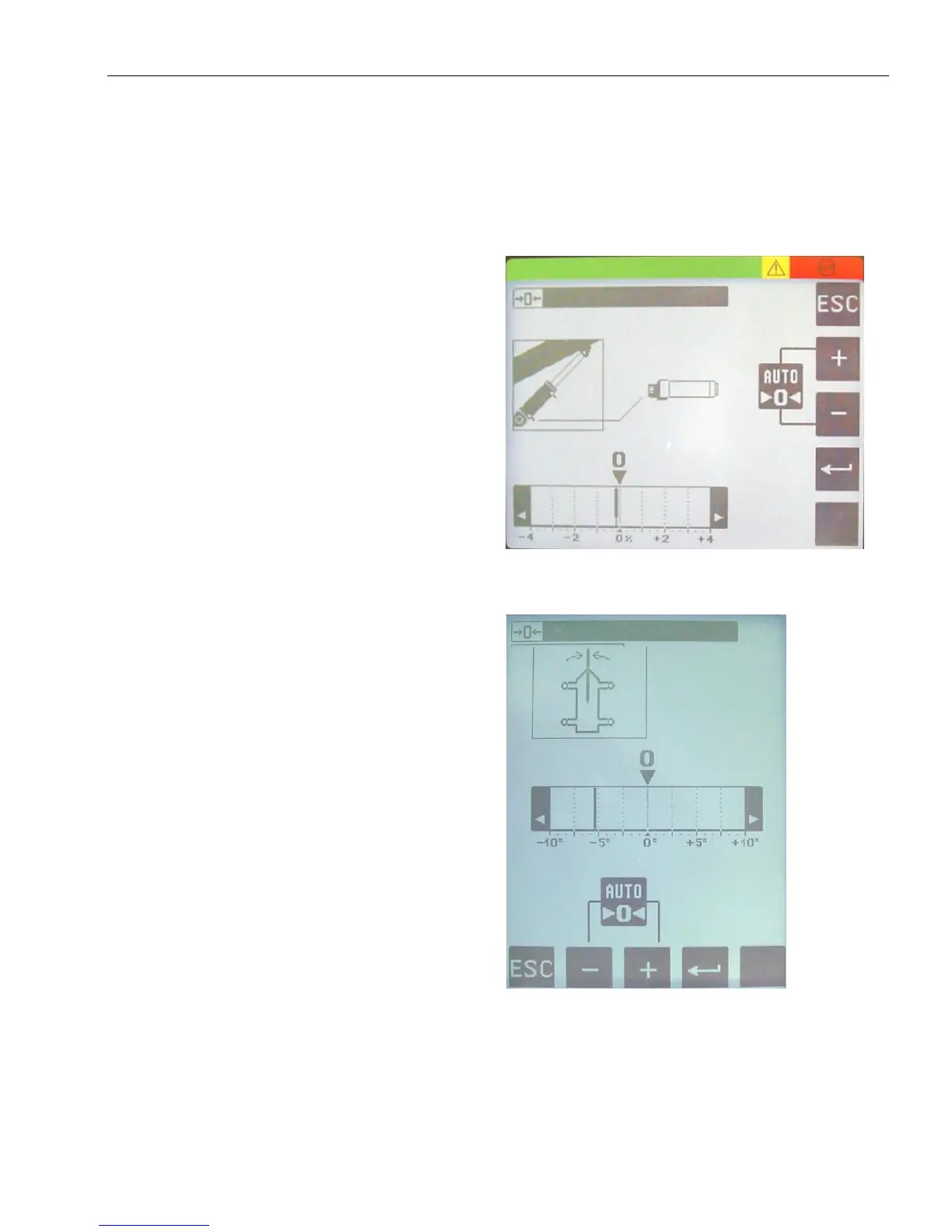

Now, having successfully entered a valid

password, the piston-side zero-point setting

function is activated. Press enter through the

piston and rod zero adjustment screens to the

slew zero-point adjustment function is activated.

An indicator line shows the current position of

the slew pot signal. Note: the indicator line must

be shown in the display scale from -10° to +10°

for this zeroing procedure.

By pressing the two center keys simultaneously,

the zero setting occurs automatically. Note: The

indicator line will move to zero on the bar graph.

When the operator is finished, pressing the EXC or INFO key returns the console display to normal.

Loading...

Loading...