3) Method for managing rotor life data

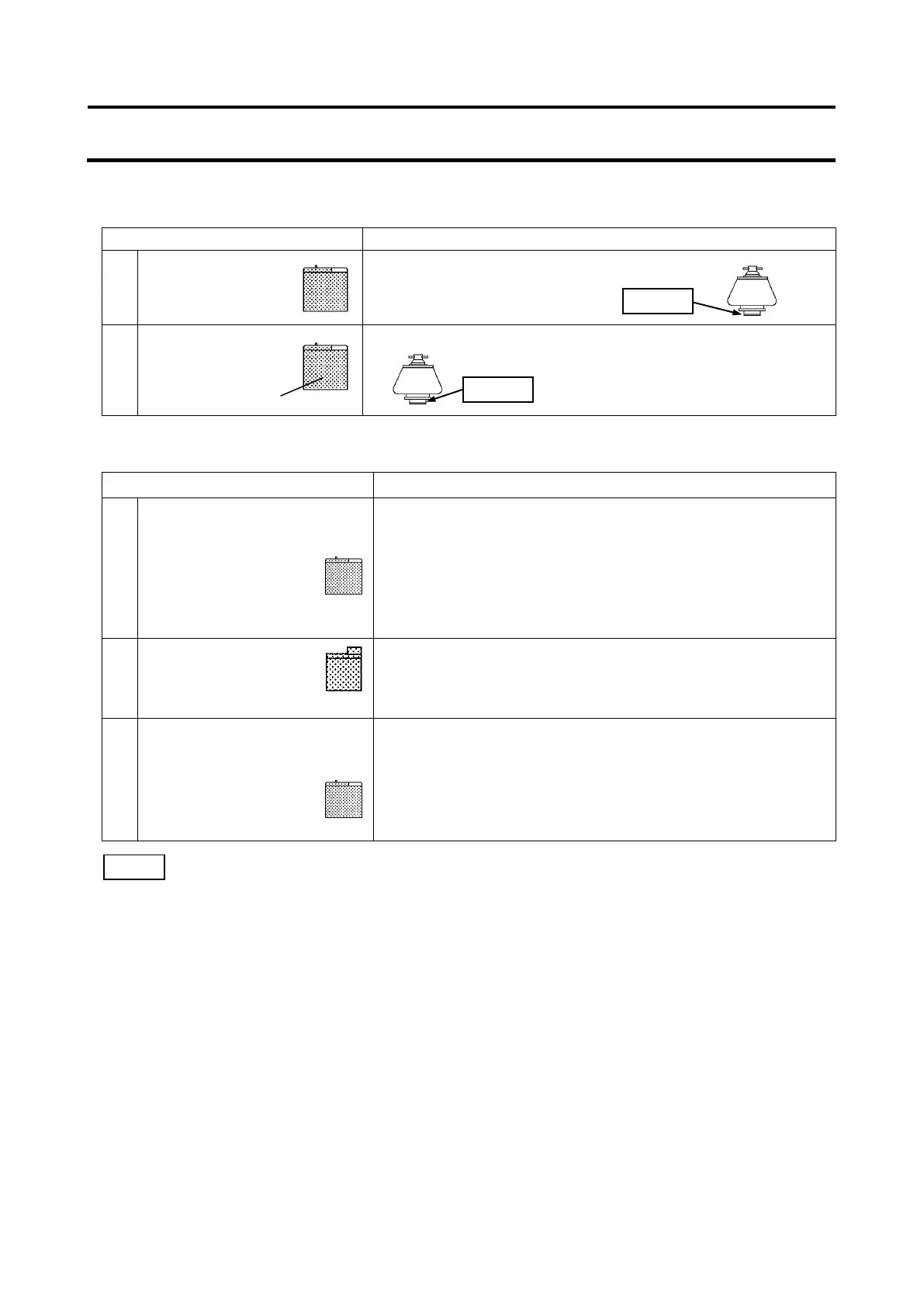

(1) For rotors with an RLM adapter used in multiple CP-NX centrifuges (automatic life management)

Data stored in RLM adapter memory

1

Total data for use in No. 1: A

2

Total data for use in No. 2: B

These steps are repeated for each

use to update the data in each

instrument.

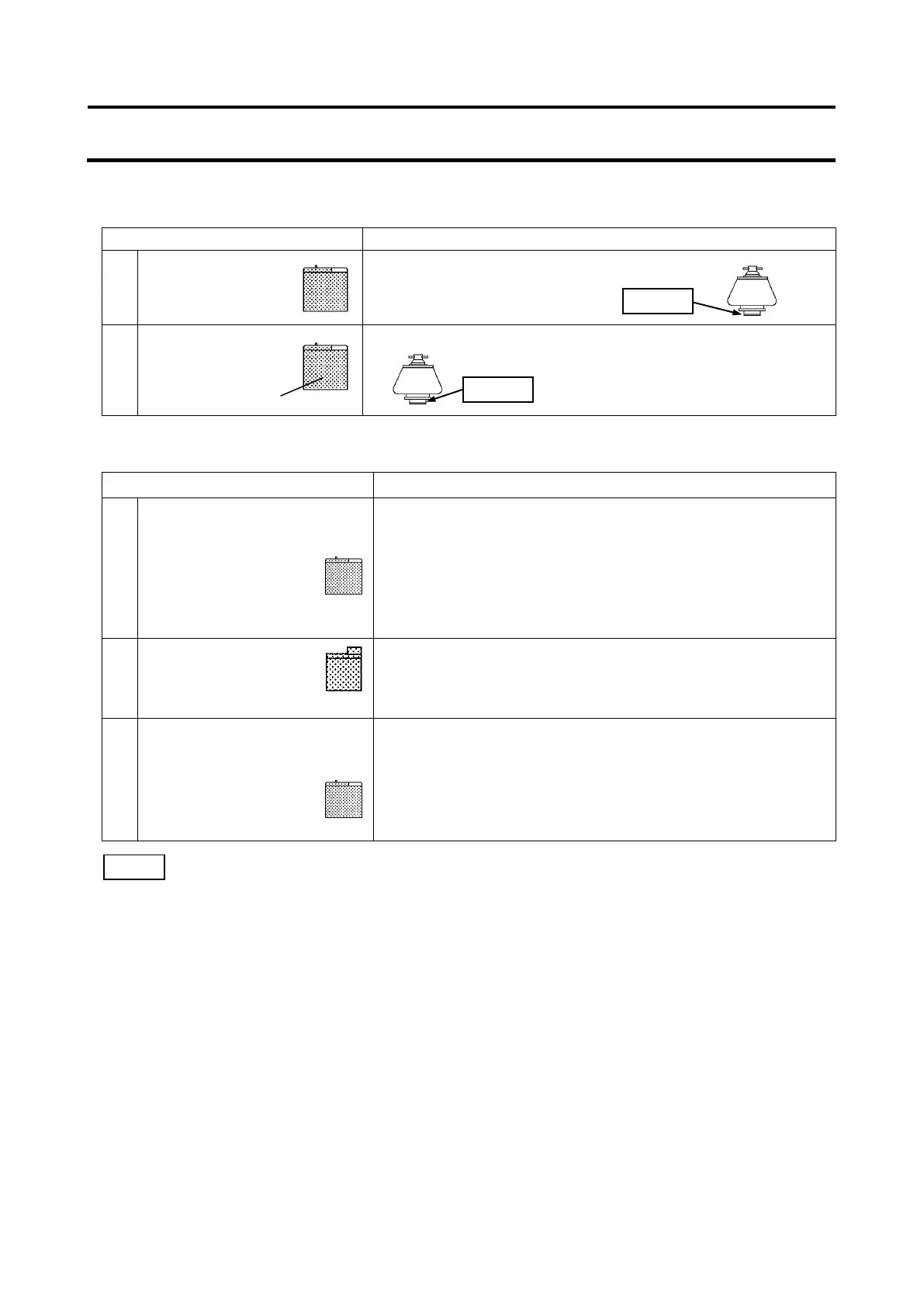

(2) For use of legacy rotors with optical disks without a life management function with the CP-NX

1

When used with multiple

CP-NX centrifuges

1) Register the rotor and its serial number in the instrument as

described in 4) "Method for registering rotors with optical

disks."

2) During operation, select the rotor you want to use referring

to the Section 3-2-3 "Rotor Selection." (Operation results

are recorded.)

3) Enter operation data in a "rotor log."

2

Using a legacy product

without life management

function in multiple

Enter operation data in a "rotor log."

3 When used in the CP-NX

again

1) Add the total number of runs and total run time of legacy

products and enter the results in the CP-NX as described in

4) "Method for registering rotors with optical disks." The

operation results are updated and recorded in the

instrument.

2) Record data in a "rotor log."

NOTE

A rotor with an RLM adapter records all the data required for rotor life management in the adapter

and the data is updated with each run. This enables automatic life management of the rotor

eliminating the need for manual log entries.

When the rotor nears the end of its life, a message to this effect appears on screen.

A rotor with an RLM adapter allows automatic life management when used with multiple CP-NX

Series, CP-WX series or CP-MX Series centrifuges.

The life of a rotor with an RLM adapter can be prolonged by lowering the maximum speed. This is

because a run performed at a speed lower than maximum speed is not counted as 1 run, but as

one or more tenths of one run, for example, as five tenths (0.5).

When the rotor reaches its primary life, the maximum permitted speed automatically changes and

an asterisk (*) appears to the right of the [krpm] indication in the Rotor management screen (refer

to Section 3-2-3 Rotor Selection") simultaneous with the change in maximum permitted speed.

(The rotor should be sent to the factory for an inspection when it reaches its primary life.)

Like a rotor with an RLM adapter, a rotor with an optical disk will notify when it reaches the end of

its life as long as the rotor is registered and correctly selected each time.

Be sure to make entries in a "rotor log" each time a rotor with an optical disk is used. The rotor

life management data stored in the instrument is not covered by the warranty. Note that failure to

properly maintain a "rotor log" may void the warranty.

3-93

Loading...

Loading...