44 SEBU7833-03

Maintenance Section

Refill Capacities

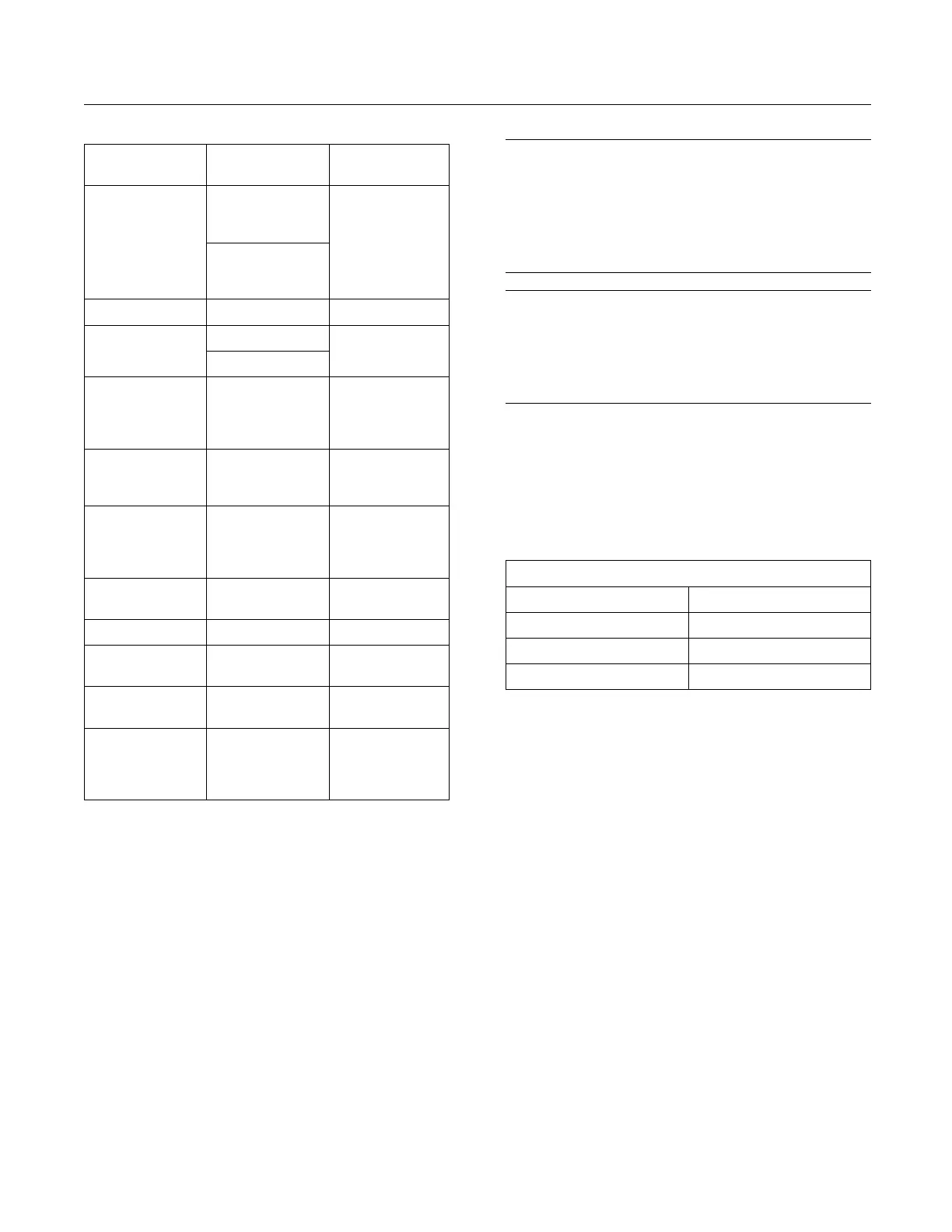

(Table 14, contd)

Copper Strip

Corrosion

No. 3 maximum

“D130”

10% at 282 °C

(540 °F)

maximum

Distillation

90% at 360 °C

(680 °F)

maximum

“D86”

Flash Point legal limit

“D93”

30 minimum

API Gravity

45 maximum

“D287”

Pour Point

6°C(10°F)

minimum

below ambient

temperature

“D97”

Sulfur

(1)

0.2% maximum “D3605”

or

“D1552”

Kinematic

Viscosity

(2)

2.0 cSt minimum

and 4.5 cSt

maximum at

40 °C (104 °F)

“D445”

Water and

Sediment

0.1% maximum

“D1796”

Water

0.1% maximum “D1744”

Sediment

0.05% maximum

(weight)

“D473”

Gum and Resins

(3)

10 mg per 100

mL maximum

“D381”

Lubricity

(4)

0.38 mm

(0.015 inch)

maximum at

25 °C (77 °F)

“D6079”

(1)

Perkins fuel systems and engine com ponents can operate

on high sulfur fuels. Fuel sulfur levels affect exhaust

emissions. High sulfur fuels also increase the potential

for corrosion of inte rnal com ponents. Fuel sulfur levels

above 0.5 percent ma y significantly s horten the oil chang e

interval. For additional information, see this publication, “Fluid

Recommendations/Engine Oil” topic (Maintenance Section).

(2)

The values o f the fuel viscosity are the values as the fuel

is delivered to the fuel injection pumps. If a fuel with a low

viscosity is used, cooling of the fuel may be required to maintain

a 1.4 cS t viscosity at the fuel injection pump. Fuels with a high

viscosity might require fuel heaters in order to bring down the

viscos ity to a 20 cSt viscosity.

(3)

Follow the test conditions and pr ocedures for gasoline (motor).

(4)

The lubricity of a fuel is a concern with low sulfur fuel. To

determine the lubricity of the fuel, use either the “ASTM D60 78

Scuffing Load Wear Test (SBOCLE)” or the “ASTM D6079 High

Frequency Reciprocating R ig (HFRR)” test. If the lubricity of a

fuel does not m eet the minimum requirements, consult your

fuel supplier. Do not treat the fuel without consulting the f uel

supplier. Some additives are not c ompatible. These additives

can cause problem s in t he fuel system.

NOTICE

Operating with

fuels that do not meet the Perkins rec-

ommendations can cause the following effects: Start-

ing difficulty, poor combustion, deposits in the fuel in-

jectors, redu

ced service life of the fuel system, de-

posits in the combustion chamber, and reduced ser-

vice life of the engine.

NOTICE

Heavy Fuel Oil (HFO), Residual fuel, or Blended fuel

must NOT be used in Perkins diesel engines. Severe

component wear and component failures will result if

HFO type fuels are used in engines that are configured

to use distillate fuel.

In extreme cold ambient conditions, you may use the

distillate fuels that are specified in Table 15. However,

the fuel that is selected must meet the requirements

that are specified in Table 14. These fuels are

intended to be used in operating temperatures that

are down to −54 °C (−65 °F).

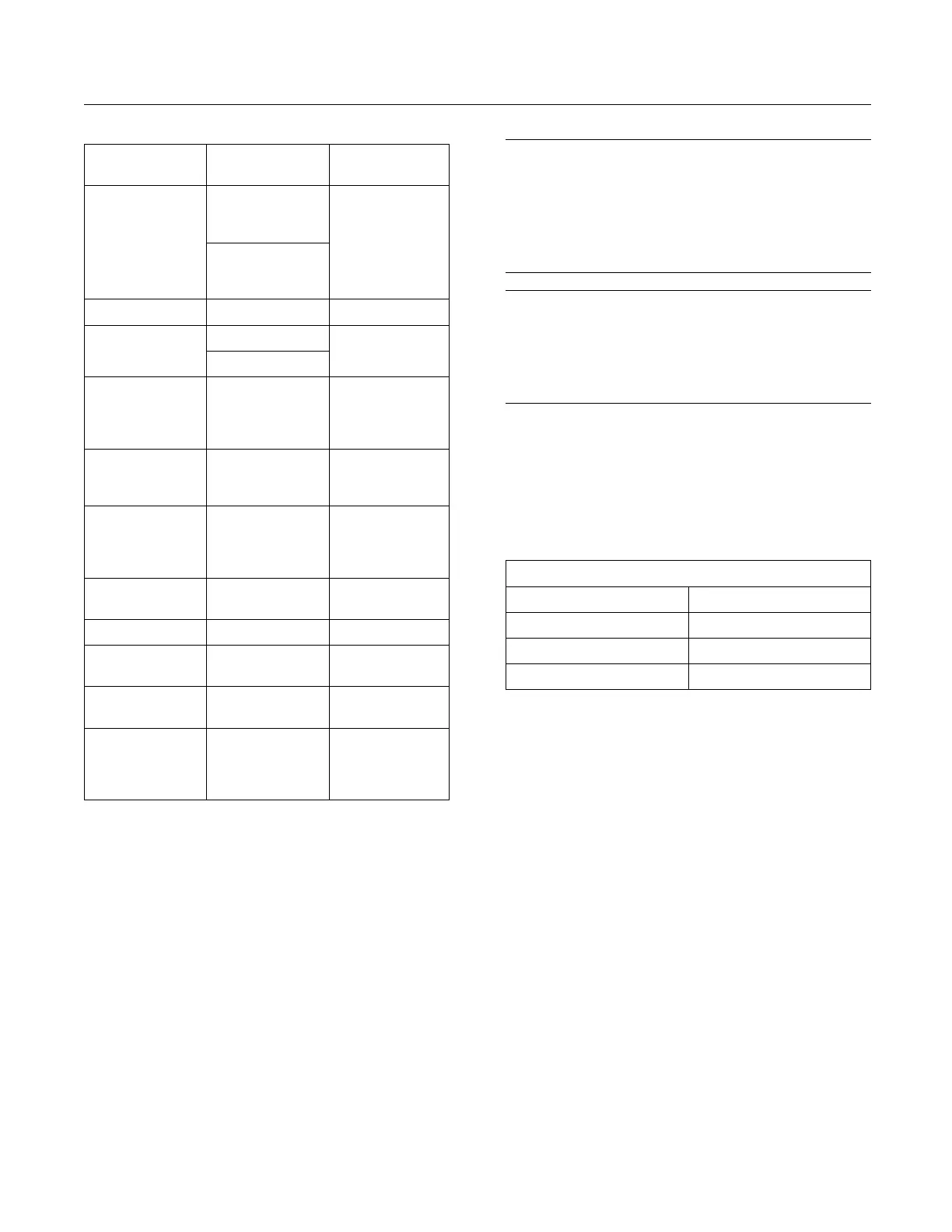

Table 15

Distillate Fuels

(1)

Specification Grade

“MIL-T-5624R” JP-5

“ASTM D1655” Jet-A-1

“MIL-T-83133D” JP-8

(1)

The fuels that are listed in this Table may not m eet the

requirements that a re specifie d in the “P erkins Specifications

for Distillate Diesel Fuel” Ta ble. Consult the supplier for the

recommended additives in order to m aintain the correct fuel

lubricity.

These fuels are lighter than the No. 2 grades of fuel.

The cetane number of the fuels in Table 15 must be

at least 40. If the viscosity is below 1.4 cSt at 38 °C

(100 °F), use the fuel only in temperatures below

0°C(32°F).Donotuseanyfuelswithaviscosity

of less than 1.2 cSt at 38 °C (100 °F). Fuel cooling

may be required in order to maintain the minimum

viscosity of 1.4 cSt at the fuel injection pump.

There are many other diesel fuel specifications that

are published by governments and by technological

societies. Usually, those specifications do not

review all the requirements that are addressed

in this specification. To ensure optimum engine

performance, a complete fuel analysis should be

obtained before engine operation. The fuel analysis

should include all of the properties that are listed in

Table 14.

This document is printed from SPI². Not for Resale.

Loading...

Loading...