55

3. User Setup

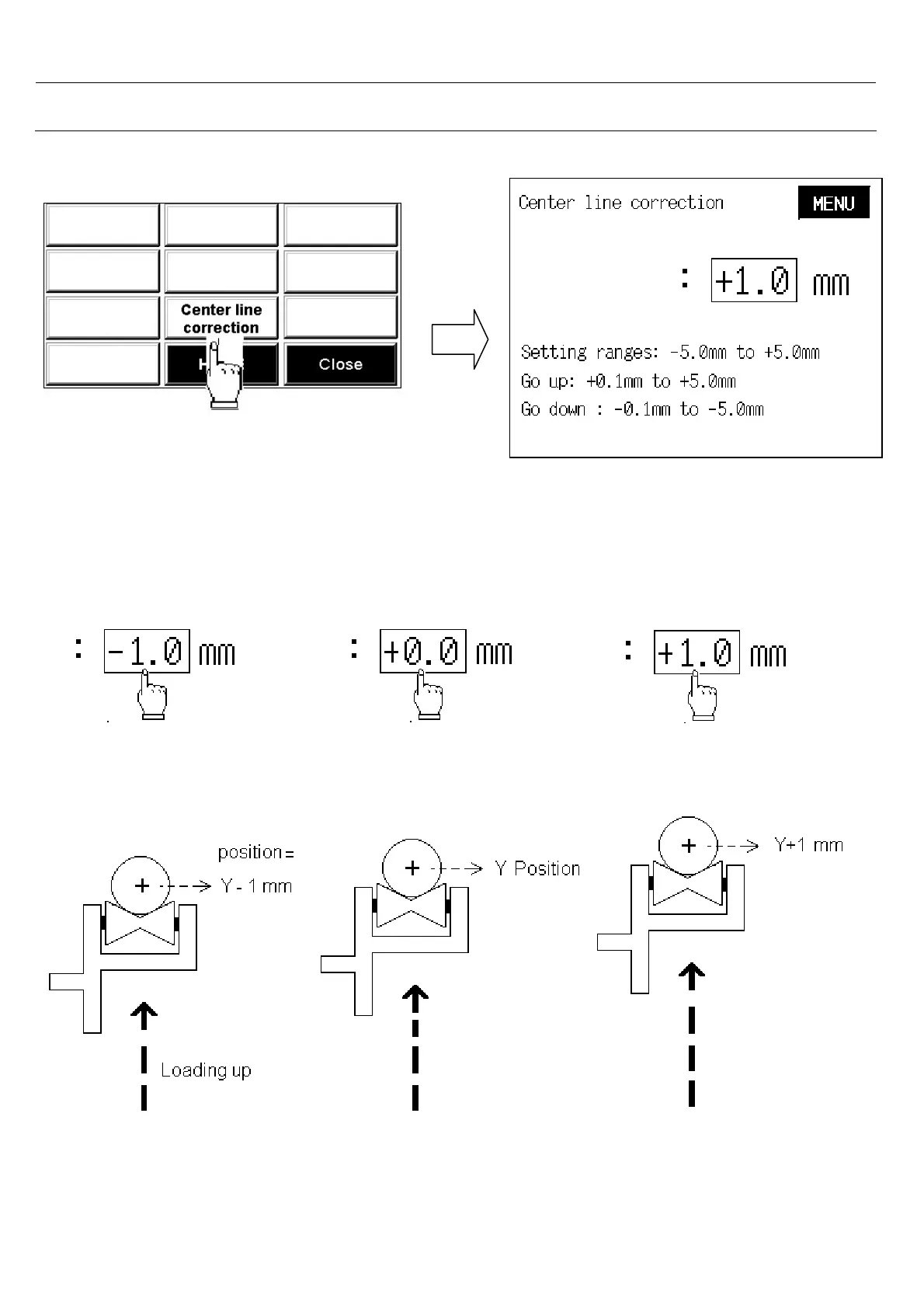

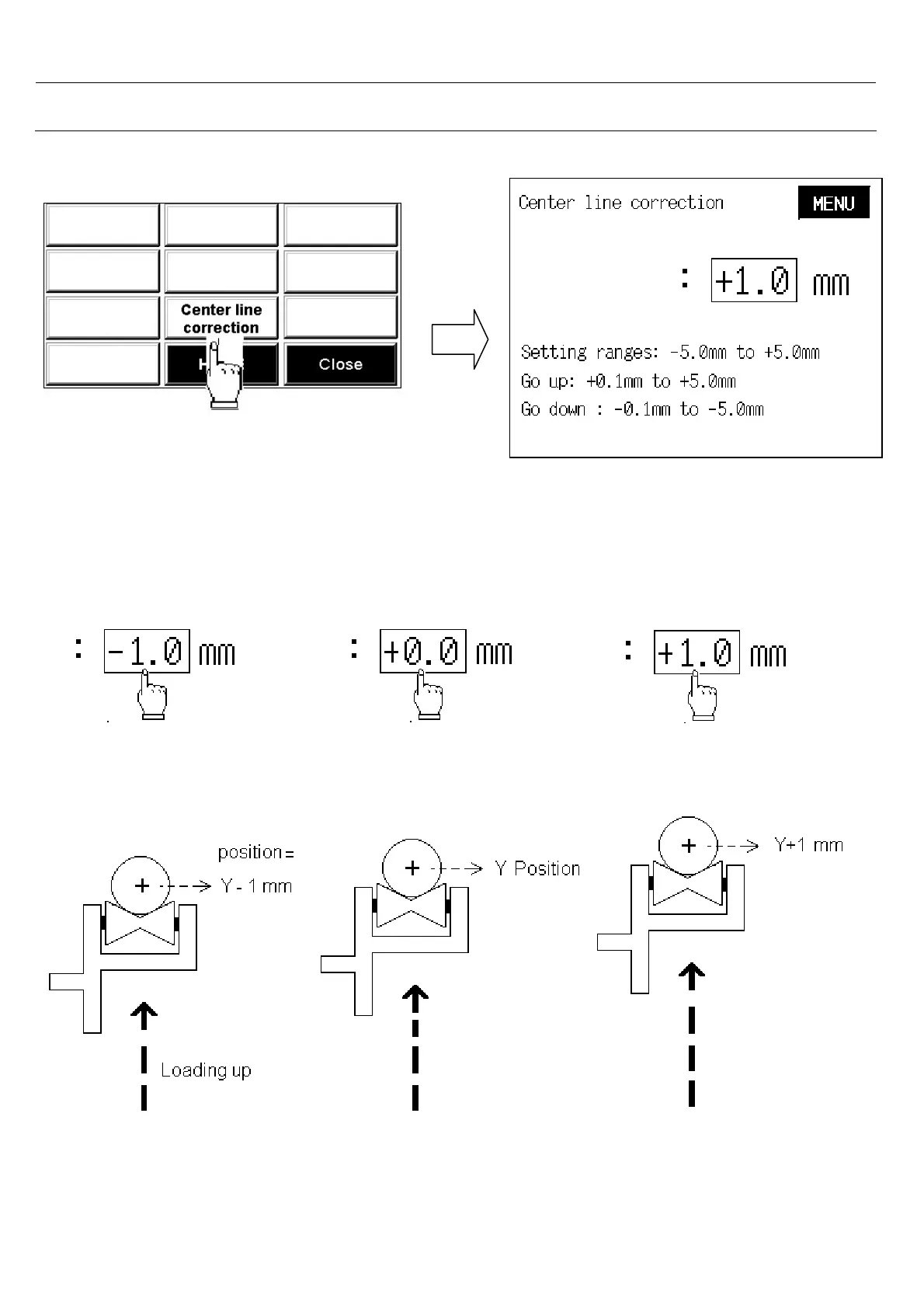

3.9 Center line correction

Select < Center line correction>

When you loading mechanism moves up

until centring active bar diameter, you

may use the Center line correction” to

compensate the error happen on the

loading up position

Loading...

Loading...