OPERATION: ARGON-HYDROGEN MANIFOLD

HySpeed HT2000 Instruction Manual 7-7

20

S2

MV4

PG3

Turn Power Supply On and Adjust Voltage/Current

1. Turn main disconnect switch ON. See Status Indicators Before

Startup in Section 6.

2. Turn on the power supply by depressing the POWER ON (1) button

(PB1) on the power supply. Ensure that the green POWER ON

indicator lights. If the POWER ON light fails to come on, see Section

4 for proper setup.

3. Set the VOLTAGE and CURRENT on the DR V/C module. Select the

arc current and arc voltage from the Cut Charts on pages 6-14

through 6-35 for the type and thickness of metal to be test cut.

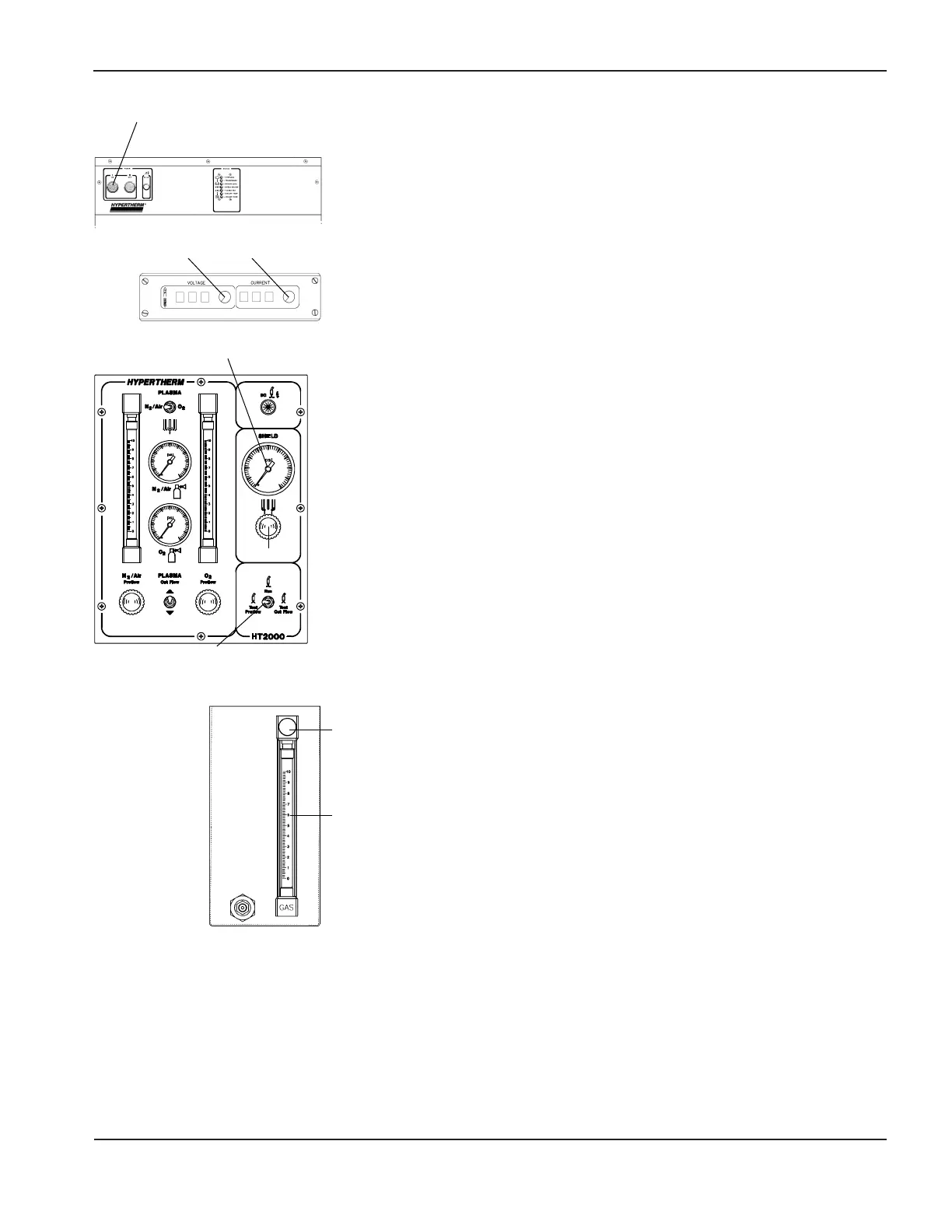

Adjust H35 Gas Flow

1. Set S2 on the gas console to Test Preflow. Verify that the argon-

hydrogen supply regulator reads 120 psi (8.2 bar).

2. Look at the flowmeter (FM1) on the argon-hydrogen manifold and set

the Preflow plasma gas flow rate % by referring to the Cut Charts and

turning the argon-hydrogen flowmeter adjust knob (MV1).

3. Look at the shield gas pressure gauge (PG3) on the gas console, and

set to the Cut Chart specifications by turning the shield gas adjust

knob (MV4).

4. Set S2 to Run after the test preflow rate has been set.

The system is now ready to run.

PB1

VOLTAGE CURRENT

MV1

FM1

Loading...

Loading...