INSTALLATION

4-34 HySpeed HT2000 Instruction Manual

19

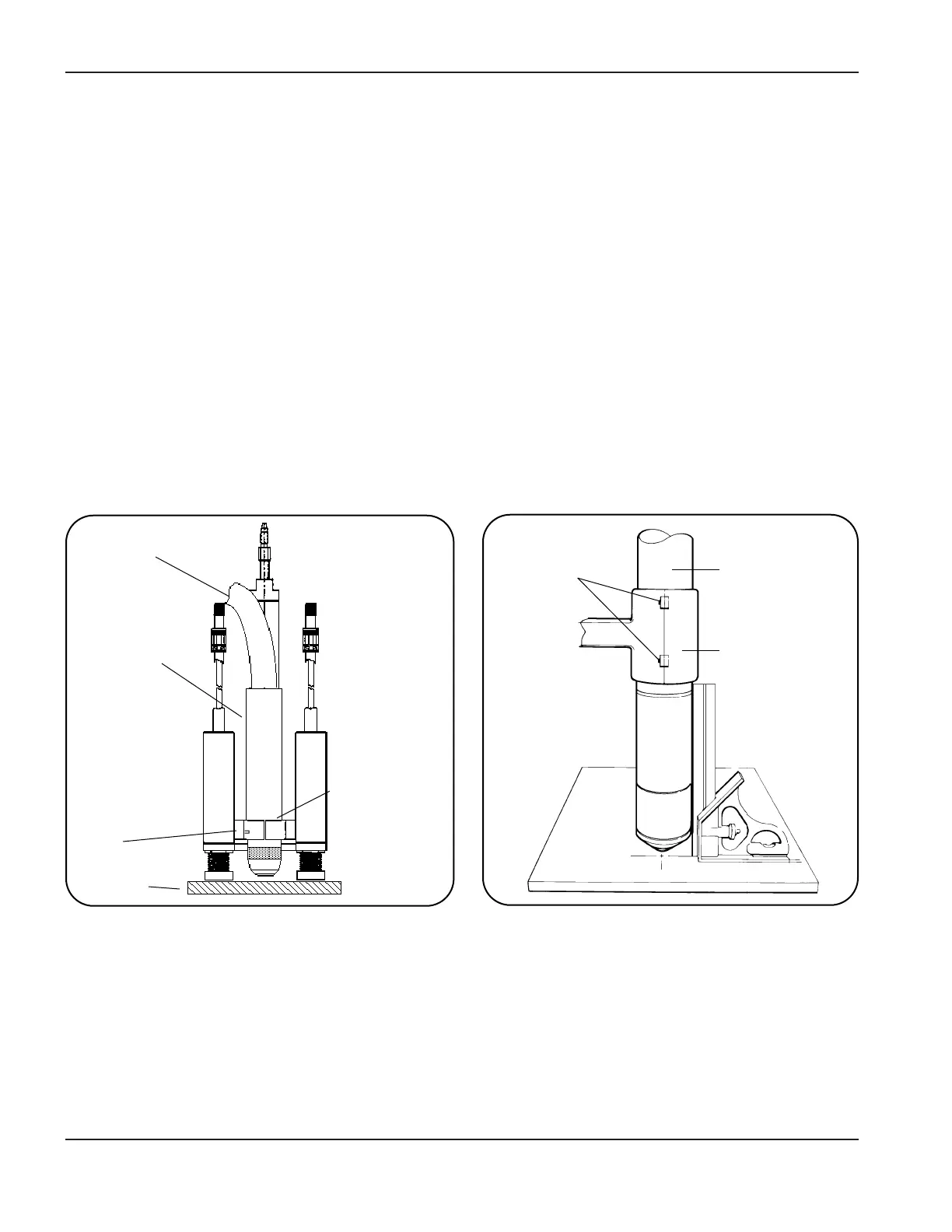

Torch Alignment

Prior to cutting with the machine torch, ensure that the torch is at right angles to the workpiece to get a clean,

vertical cut. Use a square to align the torch. The torch should be aligned at 0° and 90° (Figure 4-20).

Figure 4-20 Torch Alignment

(shown without IHS probes)

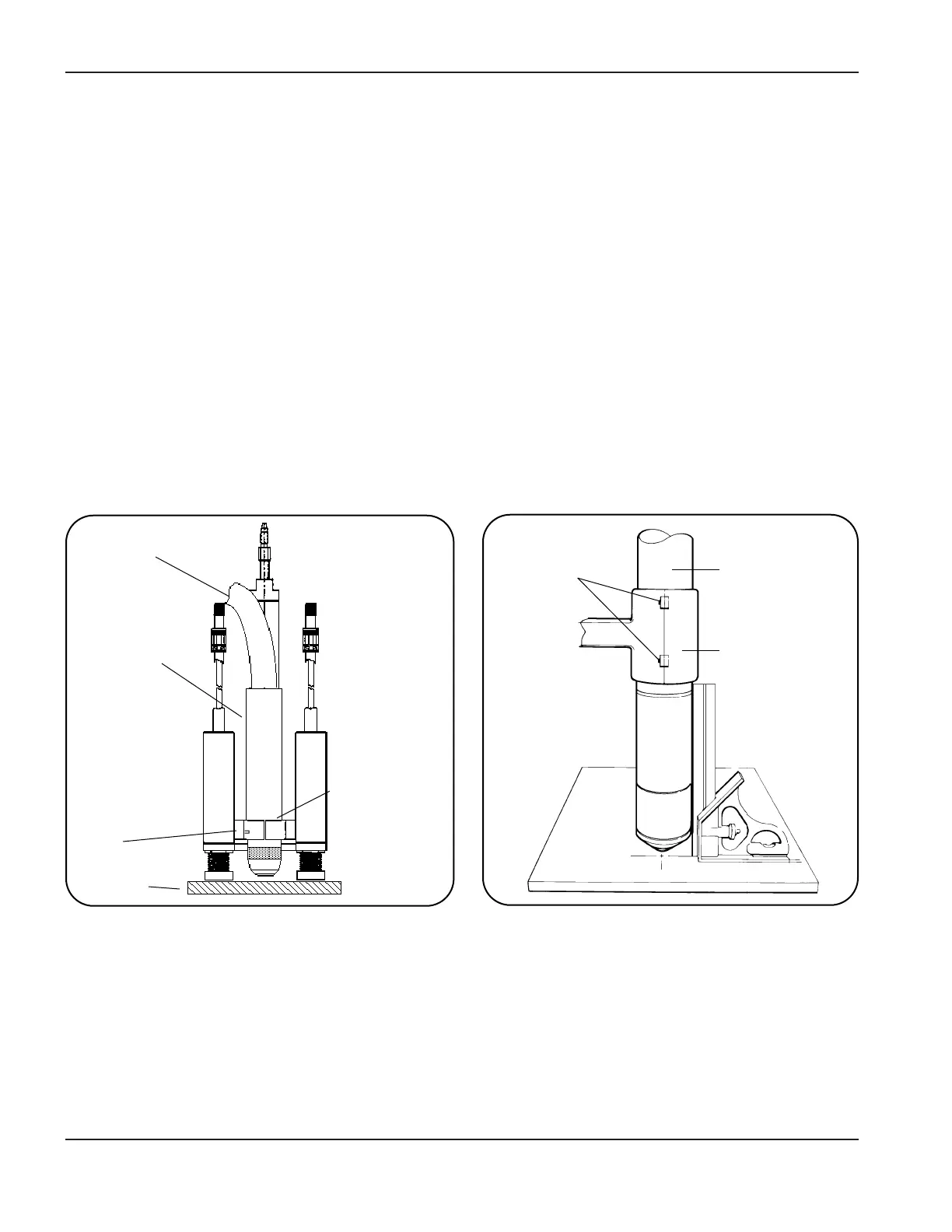

Figure 4-19 Mounting the Machine Torch

(shown with IHS probes)

Torch leads

Torch sleeve

Securing

screw

Torch mounting

bracket with IHS

Workpiece

Securing screws

Torch sleeve

Torch mounting

bracket without IHS

Mounting the Machine Torch

1. Loosen Securing screw(s) and install the machine torch (with torch leads attached) in the torch mounting

bracket or the torch mounting subassembly if IHS is used. See Figure 4-19 for torch mounting bracket with

IHS, and Figure 4-20 for torch mounting bracket without IHS.

2. Position the torch until the torch body extends all the way through the bracket, so that the bracket is now

around the plastic Torch sleeve and not touching the stainless steel torch body. Position the torch

approximately .25 " (6mm) from the work surface.

3. Tighten the securing screw(s). Final adjustment of the torch height is detailed in Section 5: Post-

Installation.

Argon-Hydrogen Connections

See Section 7: Operation: Argon-Hydrogen Manifold.

Loading...

Loading...