MAINTENANCE

8-20 HySpeed HT2000 Instruction Manual

19

8. If chopper still does not output 280V after completing step 7, there may be a problem with the control

signal or the chopper module. The chopper drive signal comes through the analog board PCB3 as an

analog level from 0 to +8 VDC, which varies the duty cycle and subsequent output current of the chopper.

These analog signals are on pins 3&4 REC1 of PCB3 for CH1, and 5&6 REC1 for CH2.

To determine if there is a problem with the chopper modules or with control board PCB2 or analog board

PCB3, proceed as follows:

• Ensure that high frequency is still disabled (see step 1).

• Disconnect PL3.1 from REC1 on PCB3.

• Place voltmeter across output of chopper and press the START command.

• If the voltmeter reads +280 VDC, then replace either control board PCB2 or analog board PCB3.

• If the voltmeter reads 0 volts, then replace corresponding chopper module CH1 or CH2.

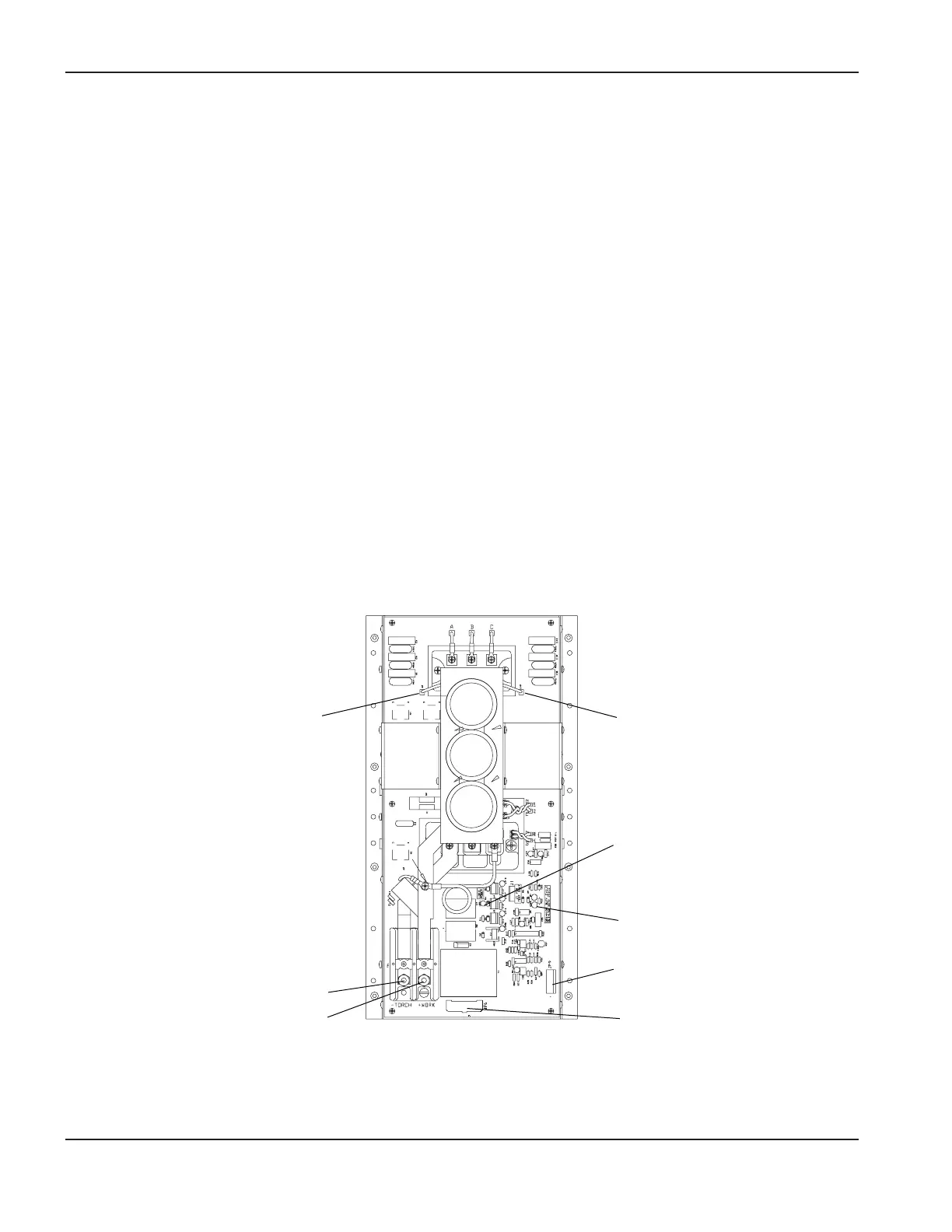

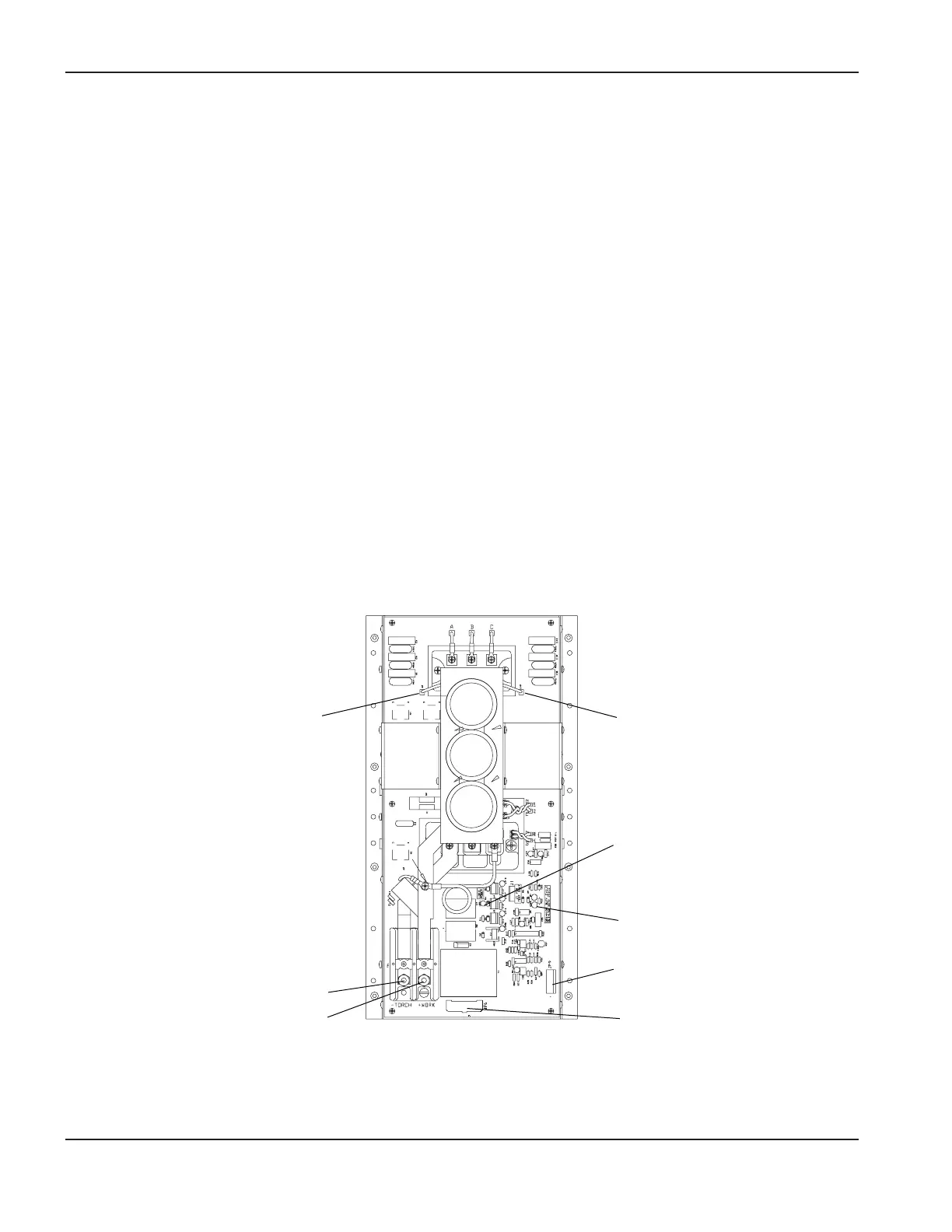

Figure 8-3 Chopper Module – Front View

Bridge (+)

- TORCH

+ WORK

Bridge (–)

LED3

LED1

JP9

JP6

Loading...

Loading...