PARTS

7-6 powermax

45

Service Manual

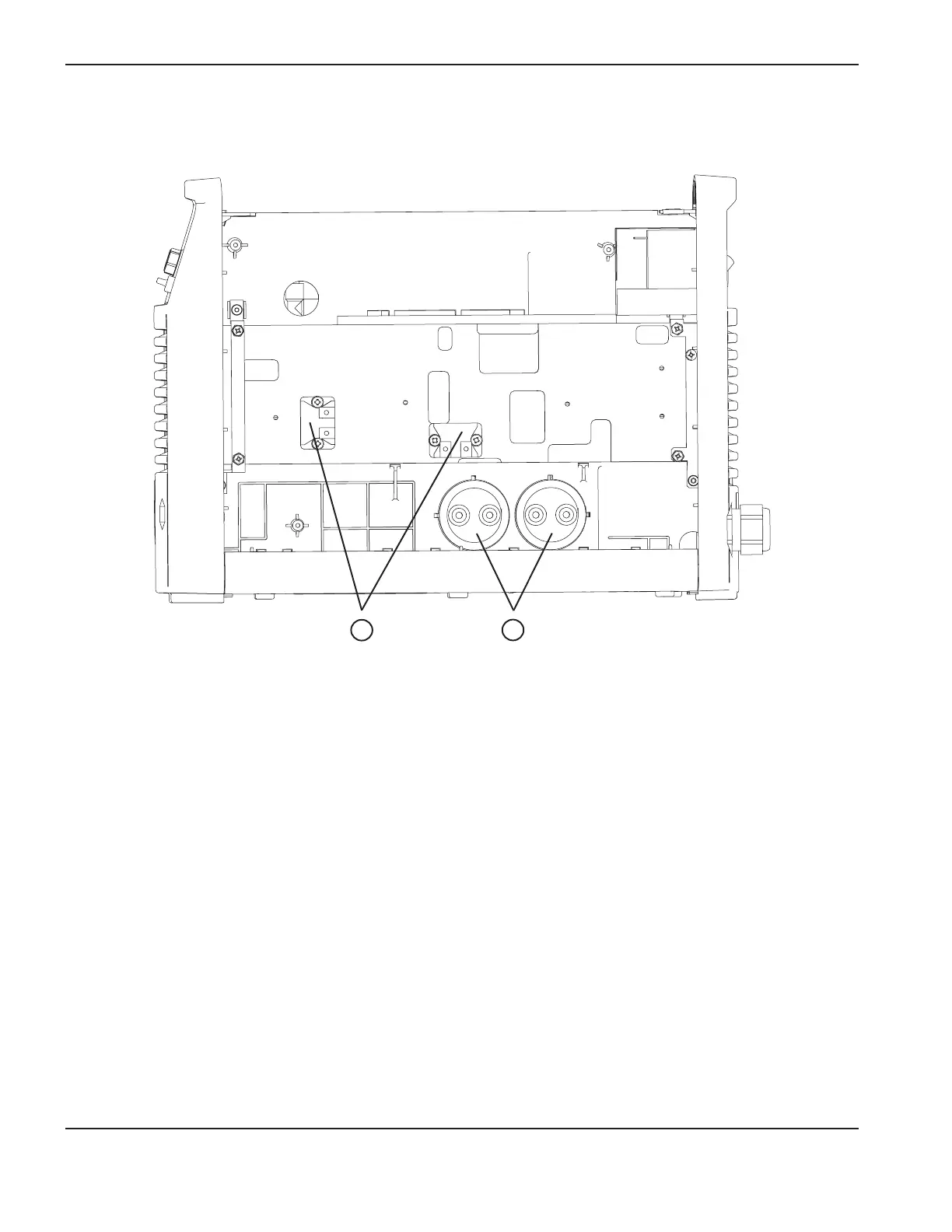

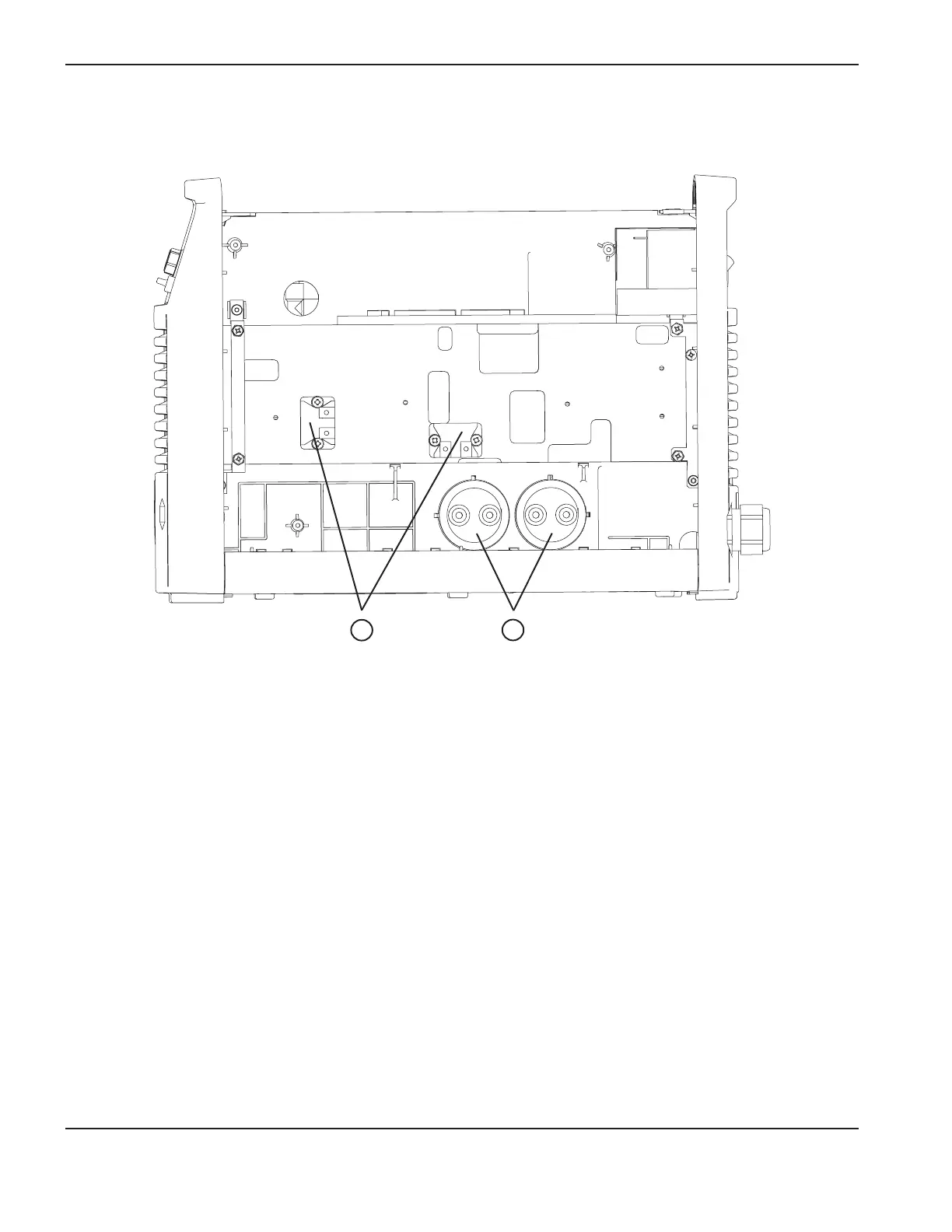

Interior, heat sink side

1

Item Part number Description Qty.

1 428065 Kit: Snubber resistors 2

2 228301 Kit: Capacitors, 200–240V CSA and 230V CE 2

228426 Kit: Capacitors, 400V CE 2

428080 Kit: Capacitors, 480V CSA 2

Loading...

Loading...